- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2KW

-

Dimension(L*W*H):

-

1100*800*1750mm

-

Weight:

-

150KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Material:

-

stainless steel 304

-

Heat Exchange Surface:

-

0.5m2

-

Temperature:

-

max:260℃

-

Vacuity:

-

min:1-100bar

-

Film system:

-

Roll wipers or block wipers

-

Rotation Speed:

-

4-40rpm

-

Certification:

-

ISO9001

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Dea

-

Voltage:

-

220V

-

Power:

-

2KW

-

Dimension(L*W*H):

-

1100*800*1750mm

-

Weight:

-

150KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Material:

-

stainless steel 304

-

Heat Exchange Surface:

-

0.5m2

-

Temperature:

-

max:260℃

-

Vacuity:

-

min:1-100bar

-

Film system:

-

Roll wipers or block wipers

-

Rotation Speed:

-

4-40rpm

-

Certification:

-

ISO9001

|

TYPE |

BML-LS-50 |

|

MATERIAL |

stainless steel 304 |

|

TEMPERATURE |

Room temp~260 ℃( heating not included ) |

|

DIAMETER |

150(mm) |

|

HEAT EXCHANGER HTA |

0.5( m2 ) |

|

FEED AMOUNT |

10~50 (L/h) |

|

ROTATION SPEED |

4-40rpm |

|

FILM SYSTEM |

Roll wipers or block wipers |

|

VACUITY |

1-100mbar(depend on the nature of material and vacuum pump) (vacuum pump not included ) |

|

COLD TRAP |

NONE |

|

FLOOR AREA |

length*width*height=1100*800*1750 (mm)(without pump) |

|

POWER |

2KW (without pump) |

|

VOLTAGE |

220V (we offer voltage transformer) |

If you want ger more details ,email us.

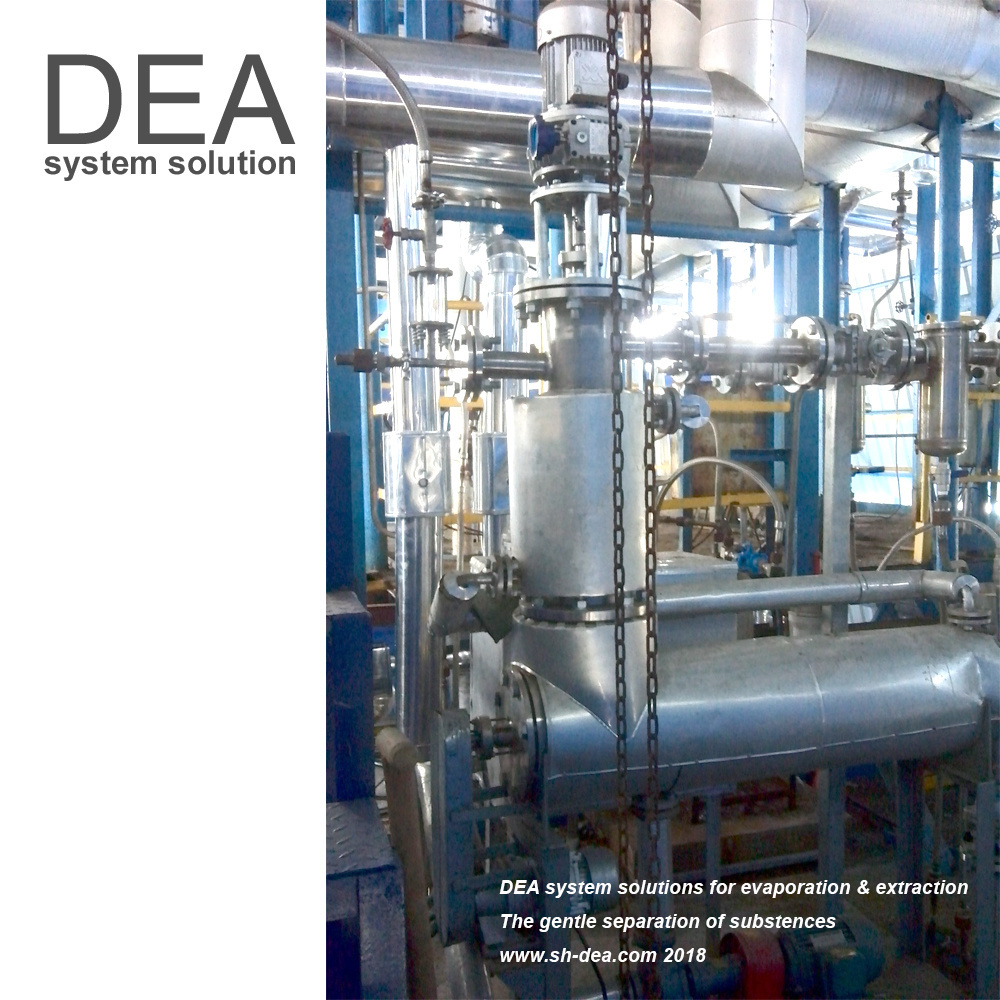

Our website:www.sh-dea.com

Our equipment has been assembled and tested prior to shipping finished, so it is a whole package, which can be used directly after unpacked. Please measure the size of the door in order to handle the equipment to the right position. For self-assembly, please inform in advance.

——Design

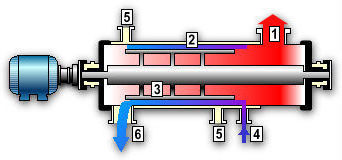

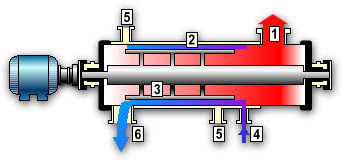

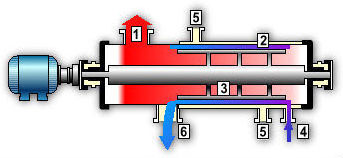

In conventional vertical mounted thin film evaporators or falling film evaporators the product film is running down the heated evaporator wall. The residence time in these vertical evaporators is depending on flow rate and viscosity, and varies between a few seconds and one minute. Depending on the wiper system, the evaporation rate is limited by the low product load at the lower part of the evaporator. In order to increase the residence time of the product in the evaporator or to increase the possible evaporation rate or increase the percent distillate, it makes sense to use horizontal evaporators, so that gravity has less influence on the product stream. In a horizontal thin film evaporator, the product is distributed at the heated evaporator wall by the rotor so that a turbulent circular ring forms at the whole evaporator surface.

1.Steam outlet

2.Evaporationg surface

3.Slicker

4.Feedstock

5.Heating inlet & outlet

6.Material outlet on the bottom

——Particular features

Possible to vary the required residence time within wide ranges.

Very high evaporation rates and also very high percent distillate splits can be achieved on horizontal thin film evaporators.

Can be used to carry out continuous reactions and reactive distillation in the thin and turbulent film at vacuum conditions by increasing the product residence time .

Suitable for reactive distillation.

Can be used as drying equipment.

Combination with a column to increase the number of stages is possible