- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DY

-

Voltage:

-

380v,50Hz

-

Dimension(L*W*H):

-

As per order

-

Weight (KG):

-

350 kg

-

Name:

-

wheat bulgur spiral screw auger inclined conveying machine

-

Keyword:

-

Screw Conveyor

-

Bucket capacity:

-

52L

-

Price:

-

Reasonable

-

Quality:

-

High level

-

Operating:

-

Easy manipulation

-

Visit factory:

-

Supply

-

Business nature:

-

Manufacture

-

Installation:

-

Engineer guide

-

OEM:

-

Accepted

Quick Details

-

Power:

-

As your requirement

-

Warranty:

-

1.5 years

-

Width or Diameter:

-

customized

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DY

-

Voltage:

-

380v,50Hz

-

Dimension(L*W*H):

-

As per order

-

Weight (KG):

-

350 kg

-

Name:

-

wheat bulgur spiral screw auger inclined conveying machine

-

Keyword:

-

Screw Conveyor

-

Bucket capacity:

-

52L

-

Price:

-

Reasonable

-

Quality:

-

High level

-

Operating:

-

Easy manipulation

-

Visit factory:

-

Supply

-

Business nature:

-

Manufacture

-

Installation:

-

Engineer guide

-

OEM:

-

Accepted

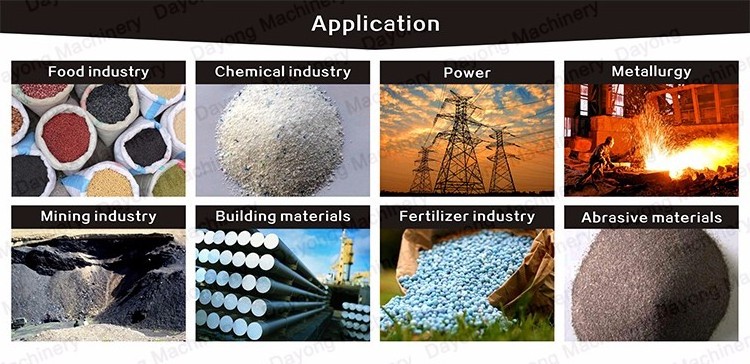

Wheat bulgur spiral screw auger inclined conveying machine

Description

B) outside tube complete with one inlet, one outlet, end flange, ball joint , inspection window.

C) standard fitting parts, middle bearing, end bearing, splined shaft coupling.

D) Lifting eyes on each tube section, convinient for transport and installtion.

E) small diameter, great efficiency, high throughout rates.

2.Conveyor has big transport capacity, long distance available.

3.Stable and controllable start, continuous and highly efficient operation.

4.The conveying could be the level or the inclined.

5.The blade could be entity spiral or belt spiral.

|

Model |

LSY 100 |

LSY 120 |

LSY 140 |

LSY 160 |

LSY 200 |

LSY 250 |

LSY 300 |

LSY 400 |

||

|

Diameter of screw (mm) |

90 |

115 |

135 |

163 |

185 |

237 |

285 |

362 |

||

|

Speed of main axis (r/min) |

300 |

300 |

300 |

308 |

260 |

200 |

170 |

170 |

||

|

Diameter of main case(mm) |

108 |

133 |

159 |

194 |

219 |

273 |

325 |

402 |

||

|

Max capacity (t/h) |

7 |

10 |

15 |

25 |

40 |

60 |

90 |

120 |

||

|

Max conveying length (m) |

8 |

10 |

12 |

15 |

18 |

25 |

25 |

25 |

||

|

Working angle (degree) |

0~60 |

0~60 |

0~60 |

0~60 |

0~60 |

0~60 |

0~60 |

0~60 |

||

|

Motor |

model |

Length≤7M |

Y90S-4 |

Y100L1-4 |

Y100L2-4 |

Y132S-4 |

Y132M-4 |

Y160L-6 |

Y180M-4 |

Y180M-4 |

|

Power (kw) |

1.1 |

2.2 |

3 |

5.5 |

7.5 |

11 |

18.5 |

18.5 |

||

|

model |

Lengtth≥7M |

Y100L1-4 |

Y100L2-4 |

Y112M-4 |

Y132M-4 |

Y160M-4 |

Y180L-6 |

Y180L-4 |

Y180L-4 |

|

|

Power ( kw) |

2.2 |

3 |

4 |

7.5 |

11 |

15 |

22 |

22 |

||

1. High efficiency, delicate design, durable, applicable to many different types of powders or viscous liquids.

2. Easy to change the mesh, easy to operate, easy to clean.

3. The materials don’t block the mesh holes. Powders don’t fly upwards. Able to sieve 500 mesh or 0.028mm

4. Able to work continually. Foreign or large particles are discharged automatically.

5. Durable, quick to change the mesh (3 to 5 minutes)

6. Small size, easy to move.

7. 5 levels can be designed at most. However, we recommend 3 levels.