- Product Details

- {{item.text}}

Quick Details

-

Finished Products:

-

Egg Box

Quick Details

-

Production Capacity:

-

6900PCS/H

-

wechat:

-

+86 13583567600

-

Color:

-

Customized Color

-

Finished Products:

-

Egg Box

Product Description

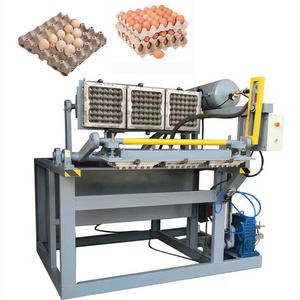

1. The production line adopts a molding machine control system in which the servo motor drags the forming machine drum

intermittently.

2. It has the advantages of accurate position and high precision.

3. High degree of automation and less people. It is currently the most advanced egg tray production line in China.

intermittently.

2. It has the advantages of accurate position and high precision.

3. High degree of automation and less people. It is currently the most advanced egg tray production line in China.

|

Capacity

|

6000pcs/h

|

|

Overall size

|

40m*12m*3m

|

|

Total power

|

371.6KVA

|

|

Total weight

|

84.1T

|

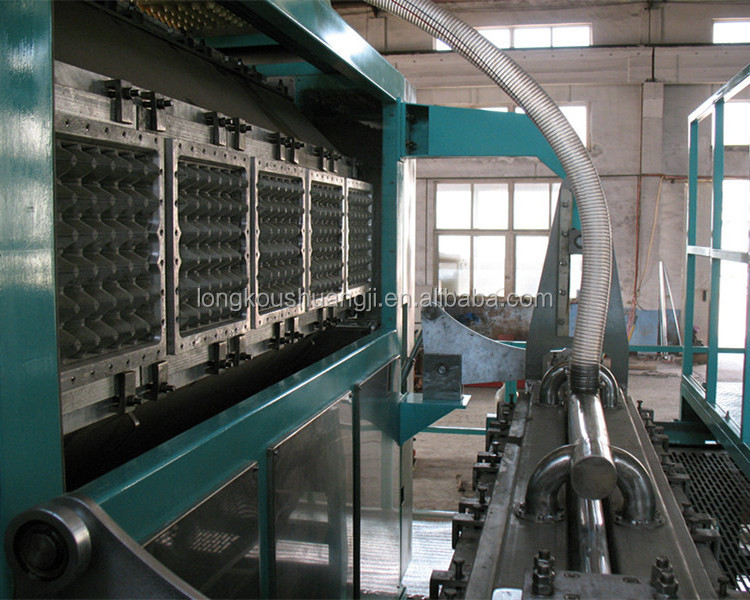

pulp making system :

Put the waster paper in to the hydrapulper, the paper and water will mix in hydrapulper ,then go to the refiner machine, refiner machine make

the pulp more small and uniform, then the pulp pump absorb the pulp to the pulp pool.

after the second mix in the pulp pool, the pulp will go to the

form machine pulp tank.

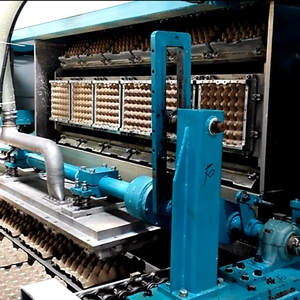

1.The vacuum pump will give the vacuum to make the forming mould absorb the pulp from the pulp tank.

2.there is a PLC control the pulp

absorb time,the finished product will be shaped on the forming mould, then the transfer mould transfer the products to the drying line, the air compressor will give the

absorb time,the finished product will be shaped on the forming mould, then the transfer mould transfer the products to the drying line, the air compressor will give the

air to blow the products, then the products

will be fall from the mould.

3.the products delivery to the drying line automatic. the water will be go back to the

water pool. will be recycle.

water pool. will be recycle.

drying system (can use gas,dissel,coal on the drying line)

1

.There are burners and blowers on the drying line.

2. burner give the hot power and the blower increase it, there will be hot air mouth

in the drying line also blow the hot air.

3.the drying line is protect by the insulation board. the degree can reach 200

degree.

degree.

automatic counting:

1. After drying line, the egg trays go to the automatic counting and stacking system, you can preset the quantity of one pile, such as

100pcs or 200pcs.

2. when the quantity ok, will be alarm. the products stacked at the same time. you can packaged them directly.

2. when the quantity ok, will be alarm. the products stacked at the same time. you can packaged them directly.

Detailed Images

Related Products

Packing&Shipping

After Sales Service

1.Engineers will go to buyer's factory for installing whole line.

2.After producing , test run of whole line.

3.The main parts of production line are one year guarantee of quality.

4.The installation and start up manual will be supplied in English.

5.Any questions will be solved at any time.

2.After producing , test run of whole line.

3.The main parts of production line are one year guarantee of quality.

4.The installation and start up manual will be supplied in English.

5.Any questions will be solved at any time.

Company Introduction

FAQ

Q:. Why we choose your company?

A: a, We are China Leading foam machine Manufacturer.

b,Our company have made foam machine about 20 years with strong experience and

advanced technics

c, Best Quality & Best Service with Competitive price.

d, 100% inspection Before Shipment. And we have got CE certificate

e, We have Professional technical team, will supply 24 hours service

f, Our machine have good quality, 1 year guarantee and lifetime maintenance

Q:What should we prepare except material?

A:You should prepare workshop, water tower, electric line, air compressor (if you need I can help you buy air compressor)

We can supply workshop layout drawing.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Longkou city, Shandong province, you can fly to Yantai or Qingdao airport, yantai airport is nearer

than Qingdao airport.

When you confirm flight No. and time please tell me then we can pick up you

A: a, We are China Leading foam machine Manufacturer.

b,Our company have made foam machine about 20 years with strong experience and

advanced technics

c, Best Quality & Best Service with Competitive price.

d, 100% inspection Before Shipment. And we have got CE certificate

e, We have Professional technical team, will supply 24 hours service

f, Our machine have good quality, 1 year guarantee and lifetime maintenance

Q:What should we prepare except material?

A:You should prepare workshop, water tower, electric line, air compressor (if you need I can help you buy air compressor)

We can supply workshop layout drawing.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Longkou city, Shandong province, you can fly to Yantai or Qingdao airport, yantai airport is nearer

than Qingdao airport.

When you confirm flight No. and time please tell me then we can pick up you

Hot Searches