- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V, 380V or customized

-

Dimension(L*W*H):

-

6m*5m*2.5m

-

Power (kW):

-

34

-

Weight (KG):

-

5000 KG

-

application:

-

motorcycle seat, bike bicycle seats, ect

-

required labor:

-

2~4 people

-

mold heating system:

-

water recycling heating

-

mold station system:

-

pneumatic controlled

-

electrical appliance:

-

Siemens

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

luzhou

-

Machine Type:

-

pu foam machine

-

Voltage:

-

220V, 380V or customized

-

Dimension(L*W*H):

-

6m*5m*2.5m

-

Power (kW):

-

34

-

Weight (KG):

-

5000 KG

-

application:

-

motorcycle seat, bike bicycle seats, ect

-

required labor:

-

2~4 people

-

mold heating system:

-

water recycling heating

-

mold station system:

-

pneumatic controlled

-

electrical appliance:

-

Siemens

Product Description

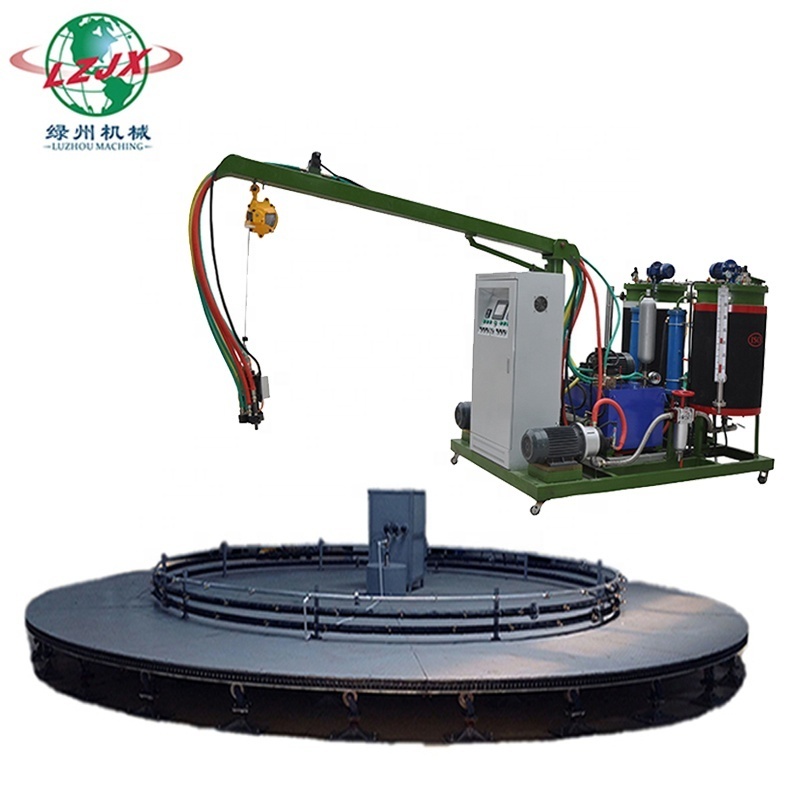

China Pu polyurethane forming machine Motorcycle seat cushion production line High Pressure Polyurethane PU Foam inject Machine

This equipment includes one pu foaming machine(can be low or high pressure foam machine) and one production line.It can be customized according to the products which the users need to produce.

Product Paramenters

|

Specification for High pressure foaming machine

|

|

|

|

|

||||

|

Model No.

|

Output(g/s)

|

tank volume(L)

|

mixing ratio

|

total Power(kw)

|

||||

|

LZ-907A

|

60-180

|

250

|

100:35-65

|

18

|

||||

|

LZ-907B

|

80-450

|

250

|

100:35-65

|

22

|

||||

|

LZ-907C

|

120-850

|

250

|

100:35-65

|

26

|

||||

|

LZ-907D

|

250-1700

|

250

|

100:35-65

|

38

|

||||

|

Specification for low pressure foaming machine

|

|

|

|

|

||||

|

Model No.

|

Output(g/s)

|

tank volume(L)

|

mixing ratio

|

total Power(kw)

|

||||

|

LZ-803A

|

15-50

|

250

|

100:35-65

|

12

|

||||

|

LZ-803B

|

30-120

|

250

|

100:35-65

|

12

|

||||

|

LZ-803C

|

60-200

|

250

|

100:35-65

|

15

|

||||

|

LZ-803D

|

100-350

|

250

|

100:35-65

|

18

|

||||

|

LZ-803E

|

150-600

|

250

|

100:35-65

|

20

|

||||

Application

This equipment is used to produce all type of polyurethane products. For example: car seat cushion, furniture seat cushion,motorcycle seat cushion, bicycle seat cushion, office chair, memory pillow, steering wheel, dash board,bumpers, insulation material like refrigerator and heaters, toys, pu cornice, casters, ect.

Details Images

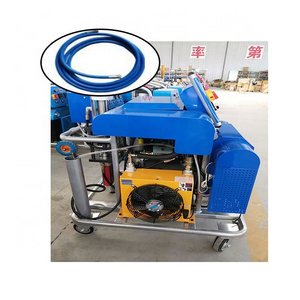

Material Tanks

Tanks inside use 304 stainless steel and heat preservation layer; with safety valve, pressure release valve, non-returnd valve, air transfer switch, stope valve. Outside has level gauge to see how many material inside clearly.

Electrical parts

Use Siemens electrical parts to keep the stability of the equipment and reduce the default problem. Imported PLC controlled system to make sure the accuracy of the ratio.

Automatic mold station

Use automatic open and close mold station can save the labor and easy to operate. We use very strong material to produce the stations to make sure the mold closing tightly.

Hot Searches