Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

according to customer

-

Dimension(L*W*H):

-

8000*9000*3000mm

-

Power (kW):

-

different

-

Weight:

-

7000

-

Screw Speed (rpm):

-

100 - 129 rpm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

PP/PE

-

machine:

-

plastic pellet making machine

-

keywords:

-

recycling plastic pelletizing machine

-

the line:

-

film pelletizing plastic machine

-

this line is:

-

PE, PP film recycling, pelletizing line

-

Name:

-

Plastic Recycling Granulator Machine

-

Usage:

-

Waste Plastic Extruder Production Line

-

Product name:

-

Plastic Granulator Pelletizing Granules Making Machine

-

Application:

-

Granules Production

-

Marketing Type:

-

Hot Product 2019

-

Screw diameter (mm):

-

120

-

Screw L/D Ratio:

-

30:1

Quick Details

-

Output (kg/h):

-

50 - 1000 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KOOEN

-

Voltage:

-

according to customer

-

Dimension(L*W*H):

-

8000*9000*3000mm

-

Power (kW):

-

different

-

Weight:

-

7000

-

Screw Speed (rpm):

-

100 - 129 rpm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

PP/PE

-

machine:

-

plastic pellet making machine

-

keywords:

-

recycling plastic pelletizing machine

-

the line:

-

film pelletizing plastic machine

-

this line is:

-

PE, PP film recycling, pelletizing line

-

Name:

-

Plastic Recycling Granulator Machine

-

Usage:

-

Waste Plastic Extruder Production Line

-

Product name:

-

Plastic Granulator Pelletizing Granules Making Machine

-

Application:

-

Granules Production

-

Marketing Type:

-

Hot Product 2019

-

Screw diameter (mm):

-

120

-

Screw L/D Ratio:

-

30:1

Plastic Pellet Making Machine/Recycling Plastic Pelletizing Machine/Film Pelletizing Plastic Machine

PE PP Plastic pelletizing machine/ granulating line

Parameters(ZL Series Sinlge/Double Stage Compactor-Granulator):

|

Model (double-stage) |

ZL85-100 |

ZL100-120 |

ZL130-150 |

ZL160-180 |

ZL180-200 |

|

Screw Diameter (mm) |

85 |

100 |

130 |

160 |

180 |

|

L/D |

25-42 |

25-42 |

25-33 |

25-33 |

25-33 |

|

Capacity(kg/h) |

150-200kg/h |

300-350 kg/h |

500kg/h |

600-700kg/h |

800-1000kg/h |

Application:

PE, PP film, Silk, Flakes (≤0.5mm), Bags, etc.

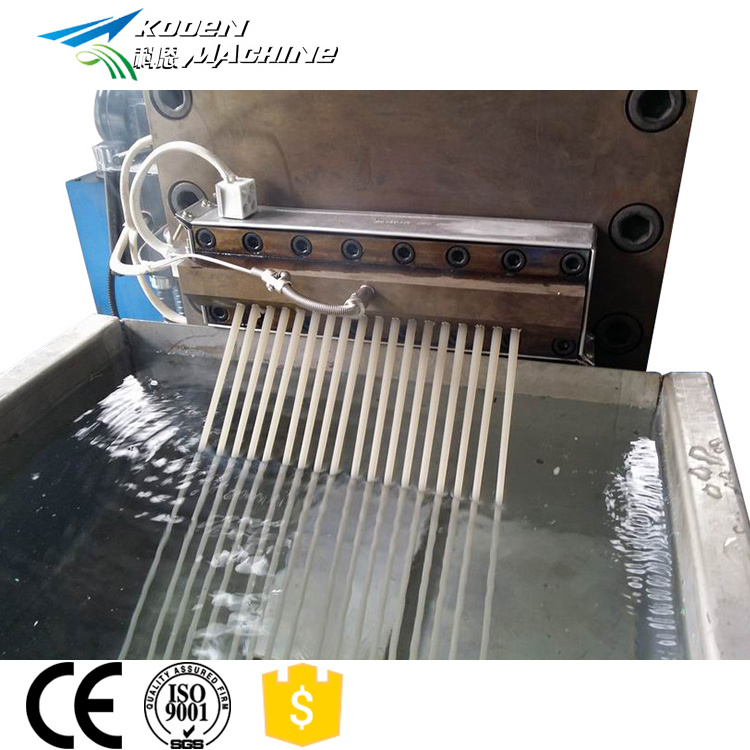

Note, our ZL series compactor granulator can be pull strip cutting method, or water ring cutting method for option

Consist of:

Belt conveyor(metal detector) → Compactor → Main extruder(vacuum degassing system) → Hydraulic screen changer → Sub- extruder → Hydraulic screen changer → Water ring cutting system →Dewatering machine → Air blow system → Storage hopper → control cabinet

Main Components:

|

Machine name |

Main specification |

|

|

|

Belt conveyor

Control method: frequency control Metal detector for selection |

|

|

|

Compactor

Rotation knives/fix knives inside Motor power: 45/55/75/90 KW Cutter material: Cr12Mov |

|

|

|

Main extruder

Screw diameter: 85/100/130/160/180mm for option Aluminum heater crew/barrel material: 38CrMoAl, Nitrify processing Equipped with vacuum pump |

|

|

|

Venting system

Quantity : 2 pieces, Vacuum pump: 1 pc |

|

|

|

Hydraulic screen changer

Motor power :2.2/3KW Special design board (no-stopping screen change, no leak) |

|

|

|

Sub extruder

Screw diameter: 100/130/160/180mm for option Aluminum heater Screw/barrel material: 38CrMoAl, Nitrify processing |

|

|

|

Hydraulic screen changer

Motor power :2.2/3KW Special design board (no-stopping screen change, no leak) |

|

|

|

Water-ring cutting system

Motor power : 2.2/3kw Frequency control |

|

|

|

Centrifugal dryer

Motor power :4/5.5/7.5KW for option Rotation speed : 1200rpm Made of SUS304 stainless steel |

|

|

|

Fan blower

Motor power : 2.2/3/5.5Kw |

|

|

|

Silo

Made of SUS304 stainless steel |

|

|

|

Control cabinet

Word famous brand electric components

|

|

Advantages:

1. Our ZL series compactor pelletizing line has pull strip cutting, and water ring cutting method(include vertical water ring cutting and horizontal water ring cutting) for option.

2. The machine with high efficiency, working stable, large capacity etc.

3. World famous brand components applied on the production line

4. The whole production line with CE certification, ISO9001 certification .

(KOOEN company more plastic recycling machine for reference)

PE/PP film washing line (with squeezer machine)

http://www.kooenmachine.com/pe-pp-film-washing-line-2/ (Website link)

http://www.kooenmachine.com/plastic-washing-line-video/pe-pp-film-bags-washing-line-video/ (Video link)

PE/PP film washing line (with centrifugal dryer)

http://www.kooenmachine.com/pe-pp-film-washing-line-2/ (Website link)

http://www.kooenmachine.com/plastic-washing-line-video/pe-pp-film-bags-washing-line-video/ (Video link)

HDPE, PP bottle(hard plastic) washing line

http://www.kooenmachine.com/hdpe-pp-rigid-plastic-washing-line/ (Website link)

http://www.kooenmachine.com/plastic-washing-line-video/hdpe-pp-bottle-washing-line-video/ (Video link)

PET bottle washing line

http://www.kooenmachine.com/pet-bottle-washing-line/ (Website link)

http://www.kooenmachine.com/plastic-washing-line-video/pet-bottle-washing-line-video/ (Video link)

ZL series single stage compactor granulator

http://www.kooenmachine.com/zl-single-stage-pepp-film-compactor-pelletizing-machine/ (Website link)

http://www.kooenmachine.com/plastic-pelletizing-machine-video/zl-sereis-compactor-pelletizing-machine-video/ (Video link)

ZL series double stage compactor granulator

http://www.kooenmachine.com/zl-double-stage-pepp-film-compactor-pelletizing-machine/ (Website link)

http://www.kooenmachine.com/plastic-pelletizing-machine-video/zl-sereis-compactor-pelletizing-machine-video/ (Video link)

SJ series double stage granulator (water ring cutting)

http://www.kooenmachine.com/sj-single-stage-pepp-film-pelletizing-machine/ (Website link)

http://www.kooenmachine.com/plastic-pelletizing-machine-video/sj-series-pelletizing-machine-video/ (Video link)

SJ series double stage granulator (pull strip cutting)

http://www.kooenmachine.com/sj-single-stage-pepp-film-pelletizing-machine/ (Website link)

http://www.kooenmachine.com/plastic-pelletizing-machine-video/sj-series-pelletizing-machine-video/ (Video link)

http://www.kooenmachine.com/squeezer-machine/ (Website link)

http://www.kooenmachine.com/recyling-machine-auxiliary-machine-video/plastic-squeezer-machine-video/ (Video link)

http://www.kooenmachine.com/shredder-machine-crusher-machine/ (Website link)

http://www.kooenmachine.com/shredder-machine-crusher-video/ (Video link)

For choosing proper machine and saving your time, please read these bellow guides carefully:

1. What material do you want to process/recycling? PE/PP film? PE/PP rigid plastic flake? PET flake? or other plastic?

2. What capacity (kg/h) do you want?

3. When (Times for delivery) do you want the machine?

4. Other requirements about the plastic film washing and recycling machine you want.

Turnkey project service:

1. we will provide all the machines for the complete production according to customer's requirements.

2. we will provide complete service for factory layout and other information to help customer to build the factory.

3. we will provide good service for machine installation and training, until the customers can run the machines and make stably production.

4. Except one year quality guarantee, we will provide after-sell service for all the life.

5. for long-term cooperation, we always provide good quality, good price and good service to customer.

KOOEN is a leading waste plastic recycling machinery manufacturer in China, dedicated to series waste plastic recycling machine with more than 20 years export experience. If you have related requirement about waste pe pp plastic film crushing washing and recycling machine/linle, please do not hesitate to let me know...

Note, If you want to see more information (video) of this plastic recycling production line, please log on our website( www.kooenmachine.com ) !

Plastic Pellet Making Machine/Recycling Plastic Pelletizing Machine/Film Pelletizing Plastic Machine