- Product Details

- {{item.text}}

Quick Details

-

Hardness:

-

Mid Hard

-

Skin Pass:

-

Yes

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

zunkai

-

Length:

-

12m

-

Grade:

-

SPCC

-

Product Name:

-

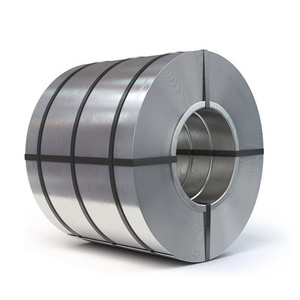

Cold Rolled Carbon Steel Coil

-

Technique:

-

Cold Rolling

-

Surface:

-

Bright Finish

-

Coil ID:

-

508/610mm

-

Steel grade:

-

SGCC/SGCD/SGCE/DX51D/DX52D/S250GD/S280GD/S350GD/G550/SPCC

-

Technology:

-

Cold Rlloed

-

Delivery term:

-

7-15workdays

-

Coil Weight:

-

3-5 Tons

-

Advantage:

-

High Corrosion Resistance

-

MOQ:

-

25

Quick Details

-

Type:

-

Steel Coil

-

Thickness:

-

0.2-0.5mm

-

Surface Treatment:

-

Normal Oiled

-

Hardness:

-

Mid Hard

-

Skin Pass:

-

Yes

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

zunkai

-

Length:

-

12m

-

Grade:

-

SPCC

-

Product Name:

-

Cold Rolled Carbon Steel Coil

-

Technique:

-

Cold Rolling

-

Surface:

-

Bright Finish

-

Coil ID:

-

508/610mm

-

Steel grade:

-

SGCC/SGCD/SGCE/DX51D/DX52D/S250GD/S280GD/S350GD/G550/SPCC

-

Technology:

-

Cold Rlloed

-

Delivery term:

-

7-15workdays

-

Coil Weight:

-

3-5 Tons

-

Advantage:

-

High Corrosion Resistance

-

MOQ:

-

25

Product Description

Chemical composition and mechanical properties of SPCC in cold load coil

Chemical composition of SPCC for cold loading: C: ≤0.12 Mn: ≤0.50 P: ≤0.035 S: 0.025

Mechanical properties: Yield strength: ≥198 Tensile strength: 315~430 Elongation: ≥33

Cold carrier paper is made from hot carrier paper. In the cold loading process, hot paper is loaded below the recrystallization temperature, and usually loaded steel is loaded at room temperature. Lead lead has low brittleness and plasticity, and needs to be preheated to 200°C before cold shipping. The class is lacking, and the surface quality and cleanliness are also very good.

The dimensional accuracy of cold-car products is high, and the performance and organization of special requirements for some products can also be fully met, such as deep drawing performance, electromagnetic performance, etc. , electrical products, automotive vehicles, aviation, precision instruments and food cans. General specifications have a thickness of 0.15-3mm and a width of 550-1530mm

It is rolling under recrystallization, but it is generally understood as rolling using normal temperature rolling materials. Aluminum cold rolling is divided into plate rolling and foil rolling. Those with a thickness of 0.15~ or more are called plates, and those with a thickness of 0.15~ or less are called foils. Europe and the United States mostly use 3~6 continuous rolling mills as cold rolling equipment.

Since there is no heating during the production process, there are no defects such as pits and scales that often occur in hot rolling, and the surface quality is good and the finish is high. Moreover, the dimensional accuracy of cold-rolled products is high, and the performance and structure of the products can meet some special requirements for use, such as electromagnetic properties and deep drawing properties.

Specifications: thickness 0.2-4mm, width 600-2 000mm, steel plate length 1 200-6 000mm.

Grade: Q195A-Q235A, Q195AF-Q235AF, Q295A(B)-Q345 A(B); SPCC, SPCD, SPCE, ST12-15; DC01-06

Performance: Low carbon steel grades are mainly used, which require good cold bending and welding performance, as well as certain stamping performance.

Specification

|

ommodity

|

Cold rolled Steel

|

|

|

|

|

Grade

|

Q195,Q215,Q235,08AL,SPCC,SPCD,SPCE,SPCEN,ST12,ST13,ST14,ST15,ST16,DC01,

DC03,DC04,DC05,DC06 |

|

|

|

|

Standard

|

ISO,JIS,ASTM,AS EN

|

|

|

|

|

Mechnical

|

Commercial / Drawing / Deep Drawing /Extra Deep Drawing/Structural quality

|

|

|

|

|

Surface treatment

|

Chromated and oiled, and ant-finger

|

|

|

|

|

Hardness

|

Softy, half hard ,hard quality

|

|

|

|

|

Thickness

|

0.12-6.0mm

|

|

|

|

|

Width

|

600-1500mm

|

|

|

|

|

Coil weight

|

5-10MT/Coil or as your request

|

|

|

|

|

MOQ

|

5MT

|

|

|

|

|

Packaging

|

Export standard, seaworthy

|

|

|

|

|

ID

|

508mm or 610mm

|

|

|

|

|

Trade Term

|

FOB, CFR, CIF

|

|

|

|

|

Transport Type

|

Container, bulk and train

|

|

|

|

|

Loading port

|

Tianjin, Qingdao,Shanghai

|

|

|

|

|

Payment terms

|

T/T, L/C at sight,West Union,D/P,D/A,Paypal

|

|

|

|

|

Delivery time

|

10-15 days after confirmed order

|

|

|

|

The cold-loaded plate roll is made of hot-loaded plate as raw material, which is loaded at room temperature below the recrystallization temperature, including plates and rolls. Among them, the ones that are exchanged in sheets are called steel plates, also known as box board cabinets; the ones that are traded in length and in rolls are called steel strips, also called coiled plates.

SPCC cold rolled coil is also called cold plate. It is made of ordinary carbon hot-rolled steel strip, which is cold-rolled into a steel plate with a thickness of less than 4mm in one step. Among them, the one made into sheets is called SPCC cold-rolled, and the roll is flat; the one that is very long and traded in coils is called steel Belt, also known as roll plate. Because it is transported at room temperature, iron oxide is not produced. Compared with hot transport coils, the average surface price and dimensional accuracy of SPCC cold transport coils are better than hot load coils, and the thickness of other products is as thin as 0.18mm. Therefore, green glaze is popular among users and widely used in automobiles, vehicles, vehicles, household industrial equipment and construction industries. In addition, SPCC cold-loaded coils are also used as substrates for further processing and become high value-added products. etc.

Chinese name

SPCC Cold Rolled Coil

commonly known as

cold plate

Mechanical properties application TA says

PRODUCTION

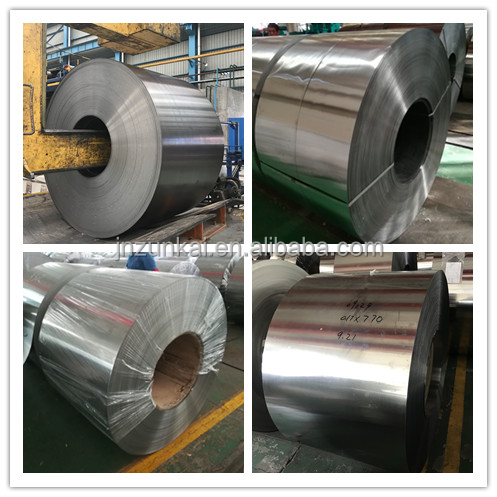

:

Raw material preparation for cold rolled sheet. The steel coils sent by the hot-rolled strip mill are cooled and stored in the steel coil warehouse in front of the pickling unit according to the type and specification, and then the steel coils are sent from the steel coil warehouse to the feeding section of the pickling unit according to the plan. Steel coil transport machine processing. , decoiling, welding, mechanical descaling and dipping in the pickling tank in the unit to remove the oxide scale on the surface of the strip and rinse it. Most of the steel strip needs to be further processed by endless rolling, while the conventionally rolled steel strip is not purified and oiled afterwards. Finally, it is rolled into specified steel coils in the unit, and stored in the warehouse in front of the rolling mill to wait for rolling. It can be fully continuous endless rolling or conventional single-coil rolling. When the cold-rolled plate adopts endless rolling, the steel coil is stored through the looper. When conventional rolling is adopted, the steel coil is uncoiled on the uncoiler in the feeding section, and the strip steel is passed into each frame in turn for rolling. And the coiler in the discharge section is re-rolled into steel coils, and sent to different units for processing according to different products.

Packing & Delivery

Hot Searches