- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Building

-

Design Style:

-

Modern

-

Place of Origin:

-

Hebei, China, Hebei China

-

Brand Name:

-

SANYE

-

Model Number:

-

Steel prop

-

Material:

-

Q195 / Q235

-

Color:

-

Customer Requirements

-

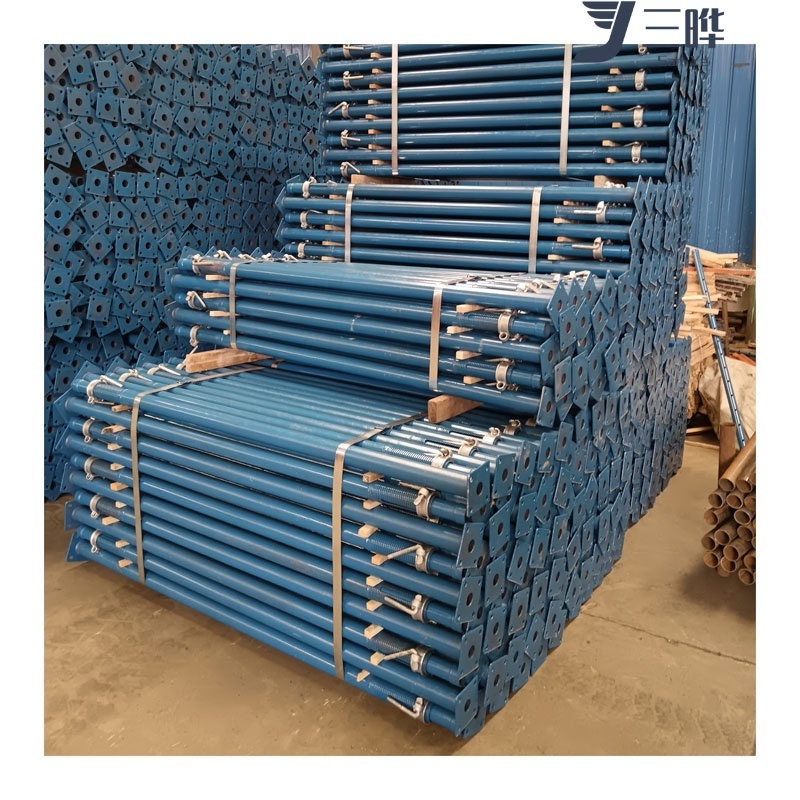

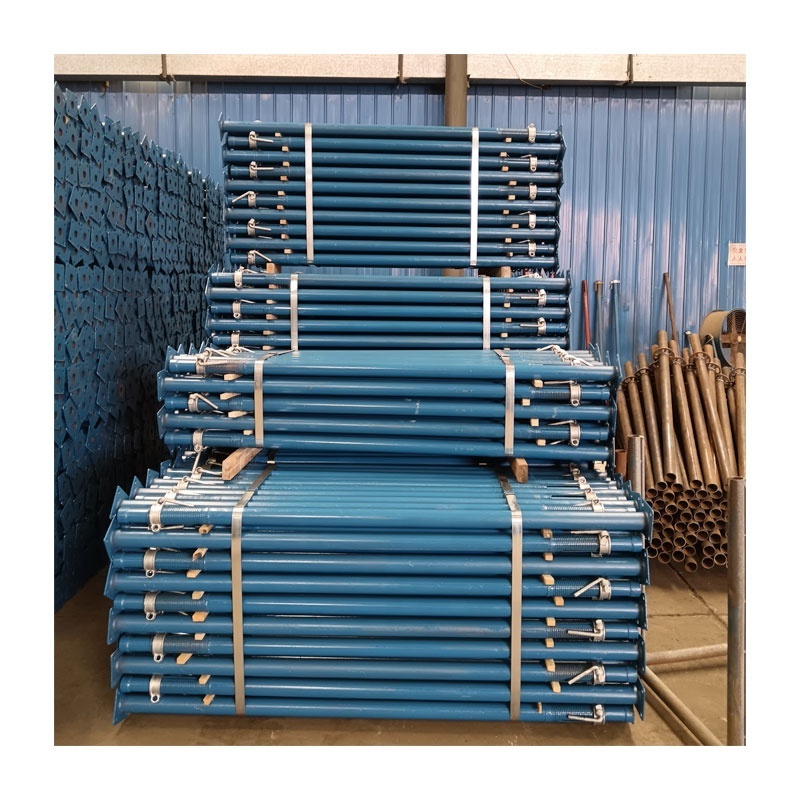

Packing:

-

Bundle

-

Advantage:

-

Stable

-

Surface treatment:

-

Galvanized/Painted

-

Certificate:

-

ISO900/ISO14001/OHSAS 18001

Quick Details

-

Warranty:

-

NONE

-

After-sale Service:

-

NONE

-

Project Solution Capability:

-

NONE

-

Application:

-

Building

-

Design Style:

-

Modern

-

Place of Origin:

-

Hebei, China, Hebei China

-

Brand Name:

-

SANYE

-

Model Number:

-

Steel prop

-

Material:

-

Q195 / Q235

-

Color:

-

Customer Requirements

-

Packing:

-

Bundle

-

Advantage:

-

Stable

-

Surface treatment:

-

Galvanized/Painted

-

Certificate:

-

ISO900/ISO14001/OHSAS 18001

Light Duty Spanish Middle East Italian 5m Building Metal Scaffolding Adjustable Steel Prop For Construc With U-Type Head

Product Description

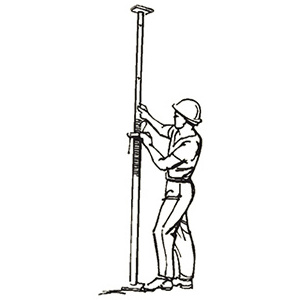

Proper Way to Use A Scaffolding Prop

When you choose to use steel supports, you must first know the height of the building so that you can choose a scaffolding prop with a suitable adjustment range.

|

Middle East Type Prop

|

|

|

|

|

||||

|

Adjustable Height

(mm) |

Inner Tube OD

(mm) |

Outer Tube OD

(mm) |

Thickness

(mm) |

Surface Treatment

|

||||

|

1800-3200

|

48

|

60

|

1.8/2.0/2.2/2.5/3.0

|

Powder Coated/

Electric galvanized/Painted |

||||

|

2000-3500

|

48

|

60

|

1.8/2.0/2.2/2.5/3.0

|

|

||||

|

2200-4000

|

48

|

60

|

1.8/2.0/2.2/2.5/3.0

|

|

||||

|

2800-5000

|

48

|

60

|

1.8/2.0/2.2/2.5/3.0

|

|

||||

|

Italian Type Prop

|

|

|

|

|

||||

|

Adjustable Height

(mm) |

Inner Tube OD

(mm) |

Outer Tube OD

(mm) |

Thickness

(mm) |

Surface Treatment

|

||||

|

1600-2900

|

48

|

56

|

1.6/1.8/2.0/2.2

|

Powder Coated/

Electric galvanized/Painted |

||||

|

1800-3200

|

48

|

56

|

1.6/1.8/2.0/2.2

|

|

||||

|

2000-3600

|

48

|

56

|

1.6/1.8/2.0/2.2

|

|

||||

|

2200-4000

|

48

|

56

|

1.6/1.8/2.0/2.2

|

|

||||

|

Spanish Type Prop

|

|

|

|

|

||||

|

Adjustable Height

(mm) |

Inner Tube OD

(mm) |

Outer Tube OD

(mm) |

Thickness

(mm) |

Surface Treatment

|

||||

|

1600-2900

|

40

|

48

|

1.6/1.8/2.0/2.2

|

Powder Coated/

Electric galvanized/Painted |

||||

|

1800-3200

|

40

|

48

|

1.6/1.8/2.0/2.2

|

|

||||

|

2000-3500

|

40

|

48

|

1.6/1.8/2.0/2.2

|

|

||||

|

2200-4000

|

40

|

48

|

1.6/1.8/2.0/2.2

|

|

||||

|

Heavy Duty Steel Prop

|

|

|

|

|||

|

Min

|

Max

|

Internal Tube

|

External Tube

|

|||

|

1.8m

|

3.2m

|

48*2.0/2.5/3.0mm

|

60*2.0/2.5/3.0mm

|

|||

|

2.0m

|

3.6m

|

48*2.0/2.5/3.0mm

|

60*2.0/2.5/3.0mm

|

|||

|

2.2m

|

4.0m

|

48*2.0/2.5/3.0mm

|

60*2.0/2.5/3.0mm

|

|||

|

2.4m

|

3.9m

|

48*2.0/2.5/3.0mm

|

60*2.0/2.5/3.0mm

|

|||

|

3.5m

|

4.0m

|

48*2.0/2.5/3.0mm

|

60*2.0/2.5/3.0mm

|

|||

|

3.0m

|

5.0m

|

48*3.5/4.0mm

|

60*3.5/4.0mm

|

|||

|

Light Duty Steel Prop

|

|

|

|

|||

|

Min

|

Max

|

Internal Tube

|

External Tube

|

|||

|

1.6m

|

3.0m

|

40*2.0mm

|

48*2.0mm

|

|||

|

|

|

48*2.0mm

|

56*2.0mm

|

|||

|

|

|

|

60*2.0mm

|

|||

|

1.8m

|

2.5m

|

40*2.0mm

|

48*2.0mm

|

|||

|

|

|

48*2.0mm

|

60*2.0mm

|

|||

|

2.0m

|

3.5m

|

40*2.0mm

|

48*2.0mm

|

|||

|

|

|

48*3.5mm

|

60*3.5mm

|

|||

Manufacture Process

Step 1,

CUTTING —

Steel pipes (both external and internal) are then cut to size with a +/-1 mm tolerance. Cutting is done using automatic cutting machines: a bundle of pipes is placed on the loader which selects one pipe at a time. It is then loaded on a positioning device and cut precisely at the desired height. Lastly, the pipe is unloaded into a container for the subsequent step.

Step 2,

DRILLING —

Then there follows the drilling step, which is carried out depending on the type of pipe. Due to the new technologies, the drilling is quick, precise and burr-free.

Step 3,

WELDING

—

External pipes proceed to the welding step, where - suitably positioned - they are assembled with the base plate and the end is threaded . Once drilled, the internal pipes undergo the same welding process but concerning the plate only.

Step 4,

COATING AND GALVANISING —

Once welded, the props can be: dip coated, cold-dip galvanised (electrolytically), for a more durable protection with respect to dip coating and for better aesthetic quality, or hot dip galvanised for a basically permanent protection, suitable for all environments and withstanding external atmospheric agents.

Step 5,

FINISH —

Depending on the product, next come the completion steps including: mounting an outer sleeve on the covered threading or a forged steel ring nut.

Step 6,

CUSTOMISATION —

Customised products are available upon request: for example with a ring nut bearing the customer’s colours, or the customisation of the prop using stickers bearing the customer’s logo.

Step 7,

PACKAGING AND SHIPMENT —

Once concluded with machining, we proceed to the packaging step. Packages usually come with 40 pieces, strapped. The material is then loaded into a truck or container and shipped.

Recommend Products

Packing & Delivery

Ton bag, wooden pallet,wooden case,iron pallet;

Customized according to customer requirements.

Hot Searches