- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YRS

-

Model Number:

-

uv marble sheet/board

-

Product name:

-

PVC UV marble sheet board

-

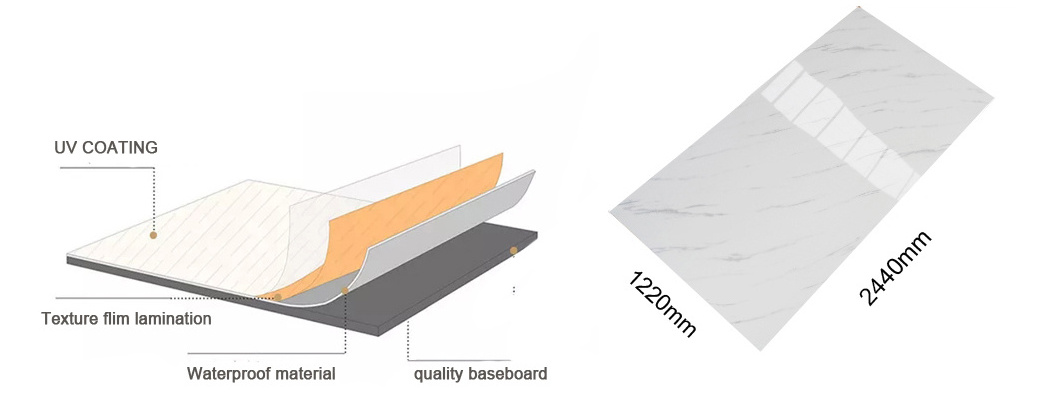

Width:

-

1220mm

-

Length:

-

2440mm 2800mm 2900mm 3000mmm

-

thickness:

-

2.0 2.2 2.3 2.4 2.5 2.8 3.0 3.2 4.0 5.0mm

-

Material:

-

SPC

-

MOQ:

-

30pcs/color

-

Surface:

-

UV protection

-

texture:

-

marble,wooden, colorful

-

surface treatment:

-

high gloss, matt

Quick Details

-

Project Solution Capability:

-

Cross Categories Consolidation, graphic design

-

Application:

-

Living Room

-

Design Style:

-

Modern

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YRS

-

Model Number:

-

uv marble sheet/board

-

Product name:

-

PVC UV marble sheet board

-

Width:

-

1220mm

-

Length:

-

2440mm 2800mm 2900mm 3000mmm

-

thickness:

-

2.0 2.2 2.3 2.4 2.5 2.8 3.0 3.2 4.0 5.0mm

-

Material:

-

SPC

-

MOQ:

-

30pcs/color

-

Surface:

-

UV protection

-

texture:

-

marble,wooden, colorful

-

surface treatment:

-

high gloss, matt

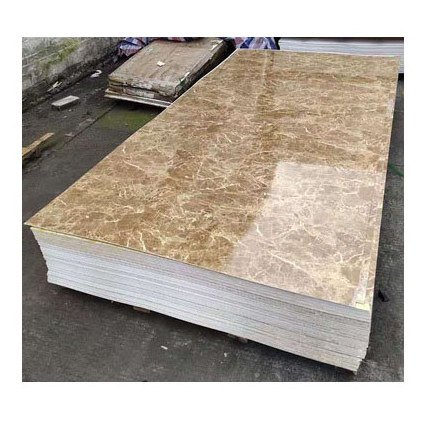

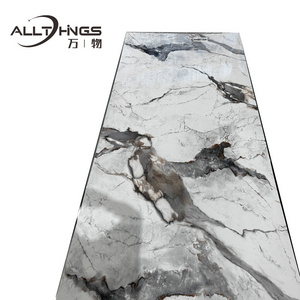

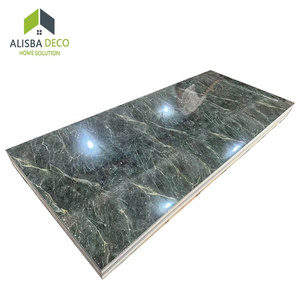

Products Description

WHAT IS UV SHEET?

UV board is a board whose surface is protected by UV treatment. UV paint is ultraviolet curing paint, also known as photoinitiated coating. Ordinary wood boards, silicon-calcium boards and other boards are painted with UV paint, and then dried by a UV light curing machine to form stone boards. They have bright surface treatment, bright color, strong visual impact, wear resistance, and strong chemical resistance. Long service life, no discoloration, easy to clean, high cost, high requirements on mechanical equipment and process technology, it is an ideal plate maintenance treatment process.

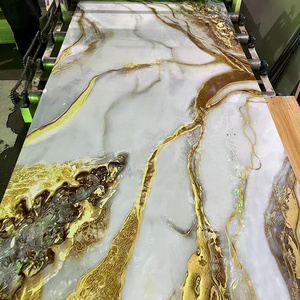

HIGH GLOSS FINISH MATT FNISH

Advantages of UV board.

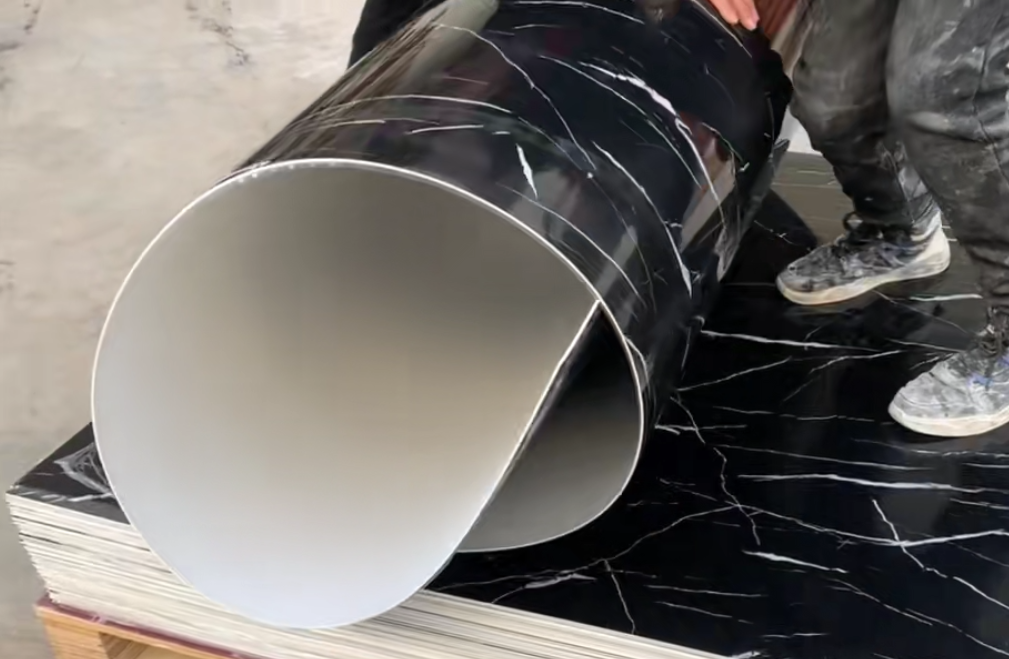

1. The surface of the UV decorative board is generally made of solvent-free environmentally friendly paint, which forms a dense protective film under the drying of UV light to prevent the release of residual harmful gases on the substrate, thereby improving the protection index of the UV board. 2. After the UV light is fixed, a very smooth protective film will be formed on the surface of the UV decorative board, which is the reflection of the specular highlight and is more beautiful. Therefore, the decorative effect is excellent, and the decorative board after light fixing has high hardness and good wear resistance. 3. The UV decorative board also performed very well in the experimental test. After light curing, the protective film on the surface is resistant to acid and alkali corrosion, and it remains unchanged during long-term use and has a long service life. It is also officially processed by the special custom process of light solid, which makes the physical properties of the UV decorative board more stable, does not fade for a long time, and can be bright for a long time, so the decorative effect is better. 4. Compared with stone, UV decorative board has its advantages, its texture is natural, but its performance can surpass natural stone. UV decorative board has crystal clear stone surface and texture, highly frosted, noble but not luxurious.

scratch resistant

flexible and strong

water and dity proof

Multy color for choose

marble texture

wood texture

CASES

Install on wall

Packing and delivery

Strong and shockproof packages.

can be directly loaded into the container, or packed by plywood pallets

Hot Searches