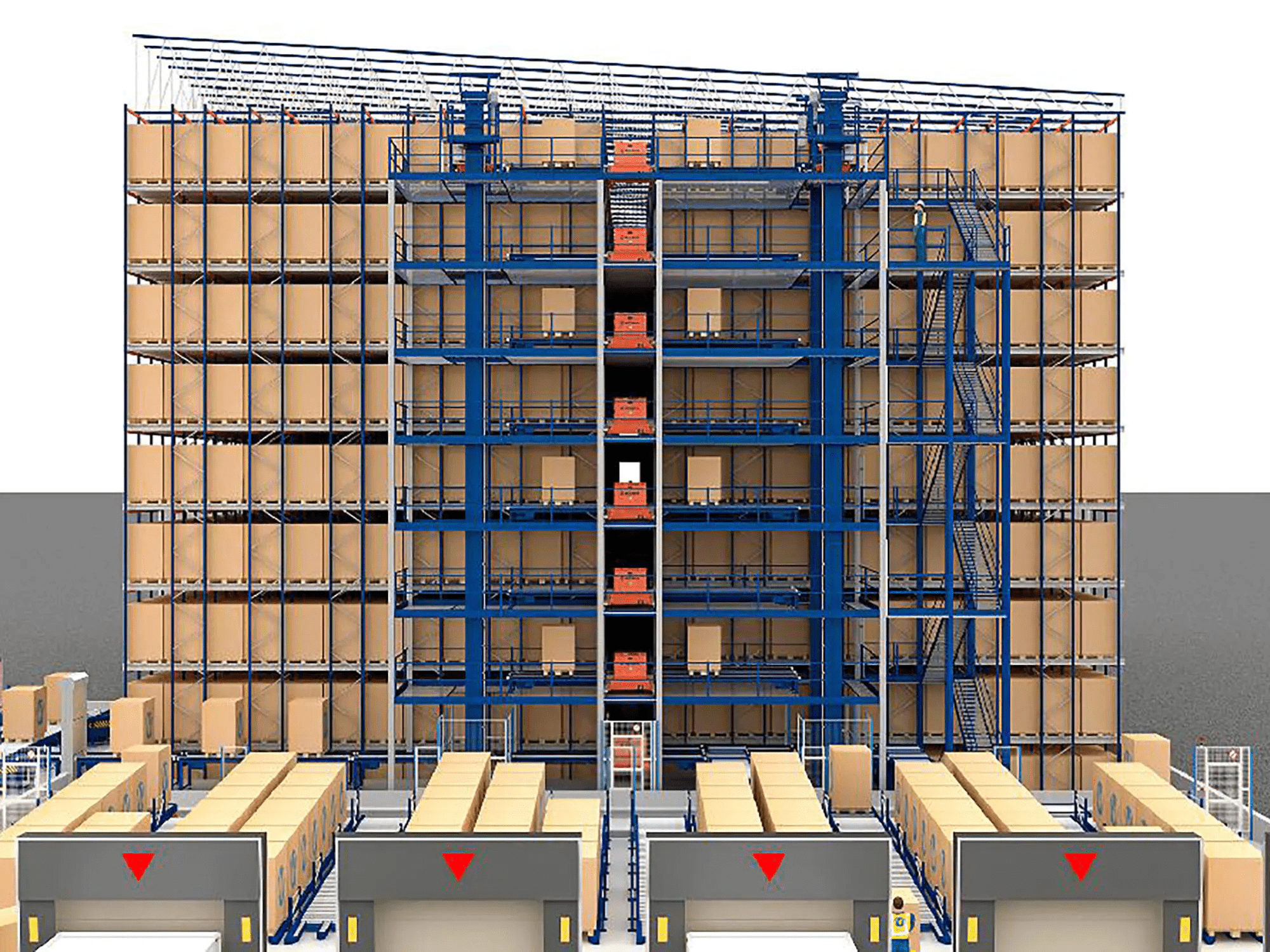

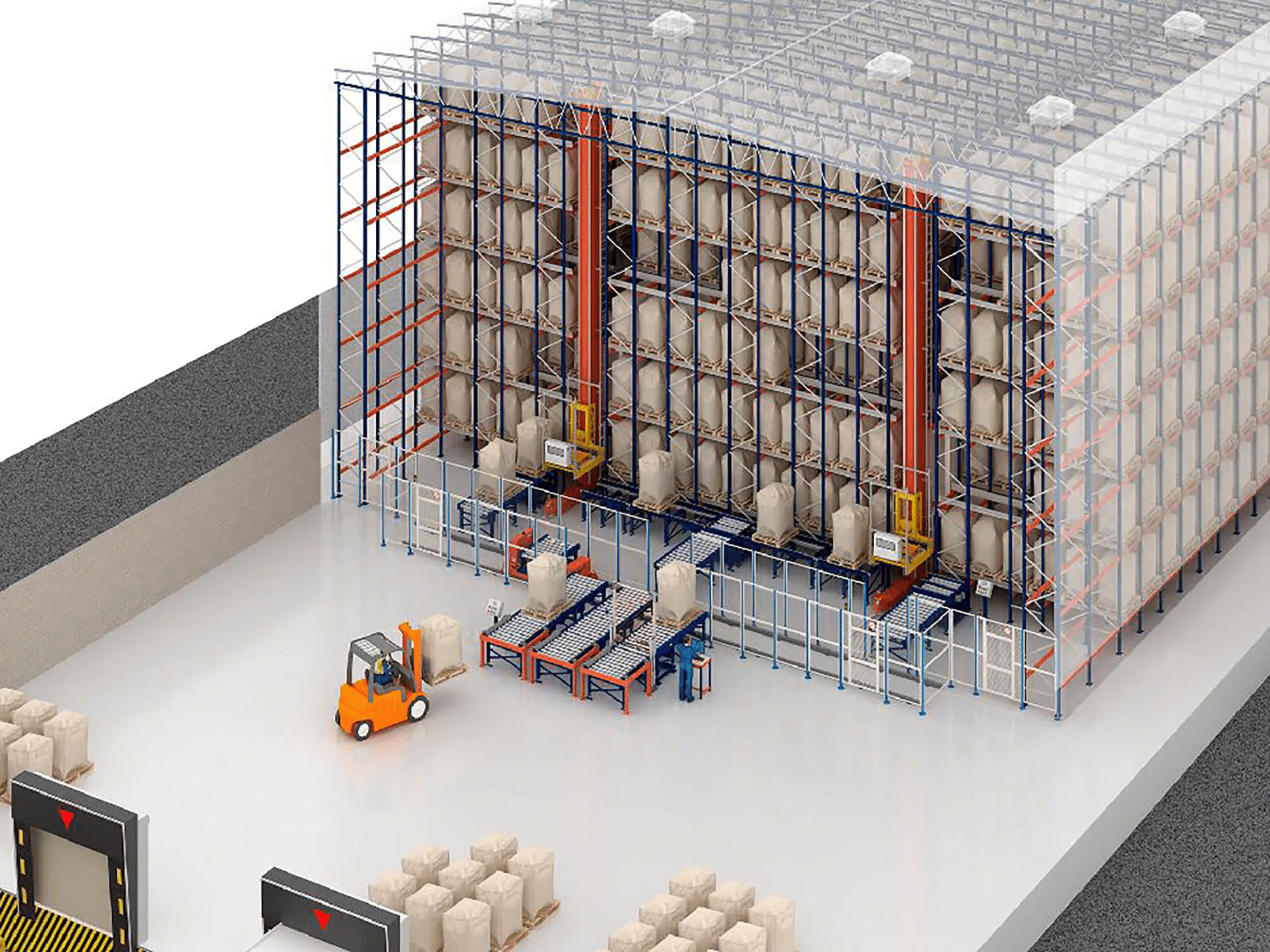

ASRS RACKING SYSTEM

(SINGLE-DEEP & DOUBLE-DEEP)

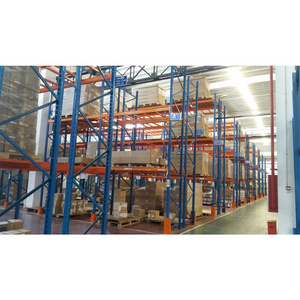

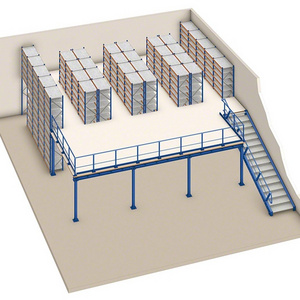

Automated Storage for Pallets & Large Loads with Stacker Crane AS/RS Systems

- Single-deep – One pallet or load is stored in each storage position in the racking.

- Double-deep – Two loads or pallets are stored in each storage position in the racking, one behind the other to increase storage

density.