- Product Details

- {{item.text}}

Quick Details

-

Power:

-

80.0kw

-

Weight:

-

4000kg

-

Dimension(L*W*H):

-

15.0*5.0*5.0m

-

Warranty:

-

2 YEARS

-

Product name:

-

puffed corn chips snacks food making machine

-

Function:

-

Extrusion

-

Type:

-

Twin Screw Extruder

-

Production Capacity:

-

100-150kg/h

-

Inverter:

-

Delta &china brand

-

Material:

-

SS304

-

Shape:

-

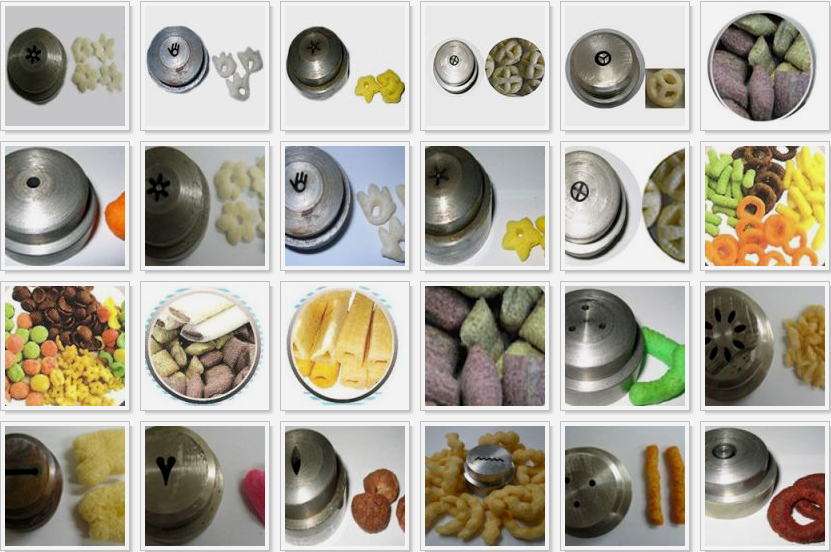

Round ball square star bone flower...

-

Usage:

-

Food Industry Equipment

-

Item:

-

Puffed Corn Snacks Making Machine

-

Package:

-

Standard Wooden Case

-

Certification:

-

BV CE

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DATONG

-

Voltage:

-

380V 50hz Three phase

-

Power:

-

80.0kw

-

Weight:

-

4000kg

-

Dimension(L*W*H):

-

15.0*5.0*5.0m

-

Warranty:

-

2 YEARS

-

Product name:

-

puffed corn chips snacks food making machine

-

Function:

-

Extrusion

-

Type:

-

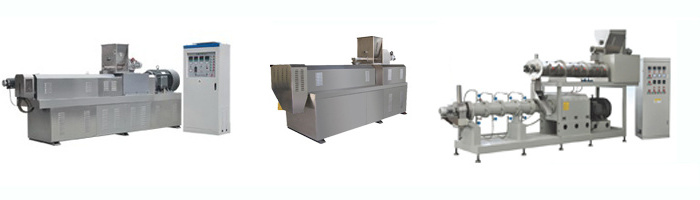

Twin Screw Extruder

-

Production Capacity:

-

100-150kg/h

-

Inverter:

-

Delta &china brand

-

Material:

-

SS304

-

Shape:

-

Round ball square star bone flower...

-

Usage:

-

Food Industry Equipment

-

Item:

-

Puffed Corn Snacks Making Machine

-

Package:

-

Standard Wooden Case

-

Certification:

-

BV CE

slanty snack bar twin screw extruder prices puffed corn chips snacks food making machine puff snack food extrusion machine

Datong company Snack food machine are equipped with the latest process technology, the core of which is the extrusion system with the extruder and the process control system .In the production process, the raw materials undergo the process steps of weighing, fine grinding, mixing,extrusion, drying, vacuum coating,cooling and packaging.

Advice and Training:

In addition to the process and plant design for the complete line, Datong provides comprehensive advice and support regarding the basic formulae and the raw materials to be used as well as intensive training of the operating personnel.

1. Raw materials of puff snack food machine :

Corn puff snack food machine adopt corn, rice, wheat, oat, barley etc as ingredients to make puffed snack. Through frication of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter.

2. Flow chart of Snack food making machine:

Mixing system---Extrusion system----Drying system----Flavoring system--Packing system

2. Products of dry snack food extruder machine:

Different shapes are made by adjusting the dies from extruder The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

3

.Advantage :

I

t is

much stronger

, Good quality and better price

, easier to clean.

1. The screw is made of alloy (38CrMoAL) by nitriding process, high strength and wear-resting. And it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

2. It adopts speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine guarantees stable materials feeding in the whole food process.

3. The gearbox has automatic lubrication function, with extends gear life.

.Mixer Function and Features:

|

|

5.Extruder Function and Features:

|

6.Oven Function and Features:

|

7 . Double drum Function and Features:

|

|

5.SLG65-III Extruder Detailed Image:

Our company engineer go to customer factory to help them and training workers on the spot.