- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380

-

Power:

-

Customers Local Voltage

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

350

-

Product name:

-

Nonstick Coating Production Line

-

Usage:

-

Cookware Coating Line

-

Installation:

-

Supplied

-

Certification:

-

CE ISO9001

-

After-sales Service Provided:

-

1 Year

-

Advantage:

-

Overseas Engineer Team

Quick Details

-

Machine Type:

-

Nonstick Coating Production Line, Coating Equipment

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Sun Glory

-

Voltage:

-

380

-

Power:

-

Customers Local Voltage

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

350

-

Product name:

-

Nonstick Coating Production Line

-

Usage:

-

Cookware Coating Line

-

Installation:

-

Supplied

-

Certification:

-

CE ISO9001

-

After-sales Service Provided:

-

1 Year

-

Advantage:

-

Overseas Engineer Team

Specification

|

Sun Glory Automatic Inside&Outside Non-stick,Cearmic Coating Line

|

|

|

|

|||

|

Workpiece

|

die casting pot,die casting frypan,forge pot,forge pan,deep drawing pan,deep drawing pot,grill pan,tawa

|

|

|

|||

|

Finish

|

(PTFE),ceramic coating,marble coating,high tempreture color painting

|

|

|

|||

|

Standard size

|

10 1/4" (total size range 4 3/4" to 12 1/2")

|

|

|

|||

|

Estmated capacity

|

8000pcs,4000pcs,2000pcs,1000pcs or 500pcs per day in 8 hours

|

|

|

|||

|

Control system

|

Mitshubish PLC,EMI,Schneider electrical components

|

|

|

|||

|

All coating system

|

Area size: 5000-500 SQM

|

|

|

|||

|

Inside processes

|

1.washing&drying 2.sand blasting 3.dust blowing 4.pre-heating for ceramic coating 5.inside ceramic base coating 6.furnace

7.mid-layer ceramic coating 8.surface ceramic coating 9.final furnace |

|

|

|||

|

Outside Processes

|

1.surface grinding 2. dust blowing 3.pre-heating oven 4.base color paint coating 5.surface color paint coating 6.furnace

|

|

|

|||

|

Energy sources

|

electricity+gas

|

|

|

|||

|

Advantage 1

|

Dupon,Whitford authorized coating line manufactruer

|

|

|

|||

|

Advantage 2

|

about 20% energy saving

|

|

|

|||

Detailed Images

We Are

Nonstick Coating Line

Manufacturer

We can help you set up nonstick cookware factory

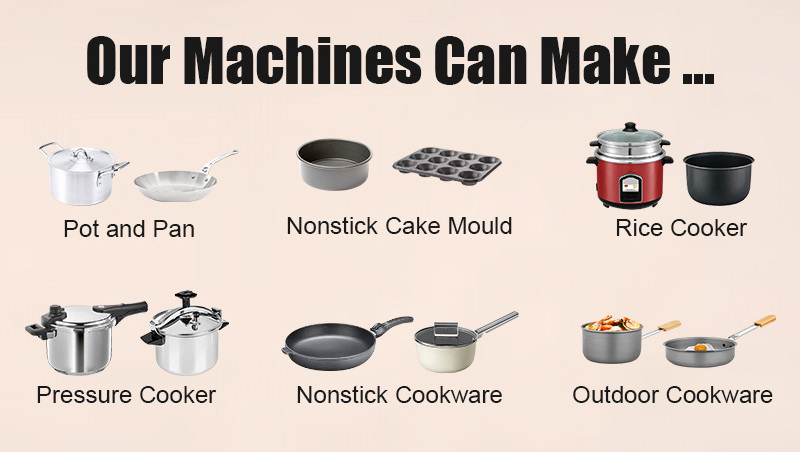

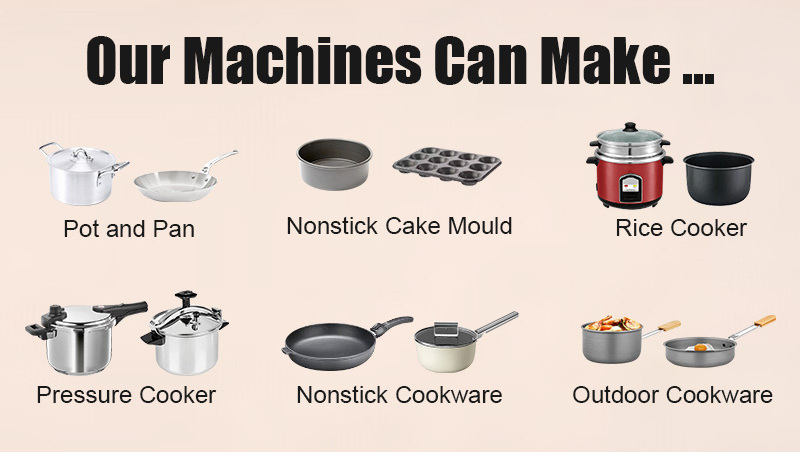

Related products

About Us

Our Advantages

After-Sales Service:

①Onsite Installation & Maintenance Service

(Our engineer can go to your factory supporting You)

②Onsite Worker Training

(Our engineer can train your workers how to operate machines)

③Machine Debugging & Testing Before Shipment

(Our engineer can go to your factory supporting You)

②Onsite Worker Training

(Our engineer can train your workers how to operate machines)

③Machine Debugging & Testing Before Shipment

Pre-Sale Service:

①Work Out Your Factory Layout And Flow Chart Designs.

②Project Feasibility Analysis

③Whole Production Line Design And Planning

②Project Feasibility Analysis

③Whole Production Line Design And Planning

Project We Have Done

We Already Set Up

52

Production Line For Our Clients.

most of our customer recover their investment within 6-24 months.

JB Cookware

Top 1 Quality In India

SS Cookware & Pressure Cooker Factory.

Bangladesh Factory

No.1 Quality Pressure Cooker

Nonstick Cookware Production Line

Biggest Cookware Factory In Algeria

Mexico Top Brand Factory

Nonstick Cookware Factory

Thailand Pot Project

Algeria Cookware Project

Automatic Glass Lid Factory

Sunglory Is Responsible For The Final Result

Certifications

Hot Searches