- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Optic

-

Single Pulse Energy:

-

70J-140J

-

Pulse Width:

-

0.1-20ms

-

Wavelength:

-

1064nm Laser Soldering

-

Focal Spot Diameter:

-

0.1-3.0mm

-

Dimensions:

-

1320*660*1100mm

-

Weight (KG):

-

220 KG

-

Core Components:

-

laser source

-

Product name:

-

Lithium Battery Tab and Electrodes scanner laser welding machine

-

Laser type:

-

YAG

-

Laser wavelength:

-

1064nm Laser Soldering

-

Application:

-

welding titanium, nickel and etc

-

Power Supply:

-

380v/50Hz

-

Keywords:

-

scanner laser welding machine

-

Pulse Frequency:

-

1-100Hz Continuous Adjustable

-

Welding depth:

-

0.1-2/2.5/3mm

-

Color:

-

Customized Color

-

CCD camera:

-

option

Quick Details

-

Max. Output Power:

-

200-600W

-

Usage:

-

welding titanium, nickel and etc

-

Laser Source Brand:

-

optic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Optic

-

Single Pulse Energy:

-

70J-140J

-

Pulse Width:

-

0.1-20ms

-

Wavelength:

-

1064nm Laser Soldering

-

Focal Spot Diameter:

-

0.1-3.0mm

-

Dimensions:

-

1320*660*1100mm

-

Weight (KG):

-

220 KG

-

Core Components:

-

laser source

-

Product name:

-

Lithium Battery Tab and Electrodes scanner laser welding machine

-

Laser type:

-

YAG

-

Laser wavelength:

-

1064nm Laser Soldering

-

Application:

-

welding titanium, nickel and etc

-

Power Supply:

-

380v/50Hz

-

Keywords:

-

scanner laser welding machine

-

Pulse Frequency:

-

1-100Hz Continuous Adjustable

-

Welding depth:

-

0.1-2/2.5/3mm

-

Color:

-

Customized Color

-

CCD camera:

-

option

Machine Parameter

Products Application

Machine Features

When compared with other welding processes, laser welding has the following advantages:

• No undercut/sink of the weld or base metal surrounding the welded area when proper techniques have been used.

• Minimal heat input to the mold base metal resulting in no or the lowest possible distortion to precision features in close proximity to the weld repair area.

• Minimal weld metal deposited resulting in minimal machining to restore the part to its original dimensions.

• Hard, tough resultant weld metal attributable to the fine grain structure of the weld metal, which is a result of the extremely rapid solidification of the laser weld.

• Extremely precise control of the weld metal location, which allows for welding within a few thousands of an inch of features that are not to be disturbed on the mold.

• Little to no discoloration of the weld and the surrounding base material.

Laser Equipment Safety

The laser equipment can be very hazardous. The high voltages present in the laser power supply and the laser cavity are lethal. Only trained personnel should be allowed to repair the laser equipment. The laser light can cause permanent damage to the eye - the collimated nature of the laser light allows for focusing of the light on the retina in the eye. Direct laser light or scattered laser light allowed to enter the eye can cause partial to total permanent blindness. A laser safety program should be initiated and laser safety training should be given to all individuals before using any laser welding system.

galvo scanner

fibel laser power

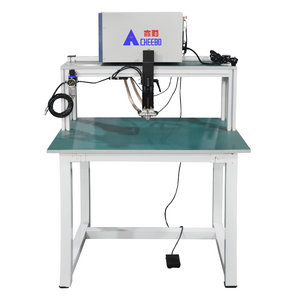

Total machine

laser power supply

Brand:OPTIC

Origin: China

power: 3kw/6kw

Do real 80J pulse energy, 5.5KW rated power, single floor model suitable with desktop size.

Stable, powerful, and smart.

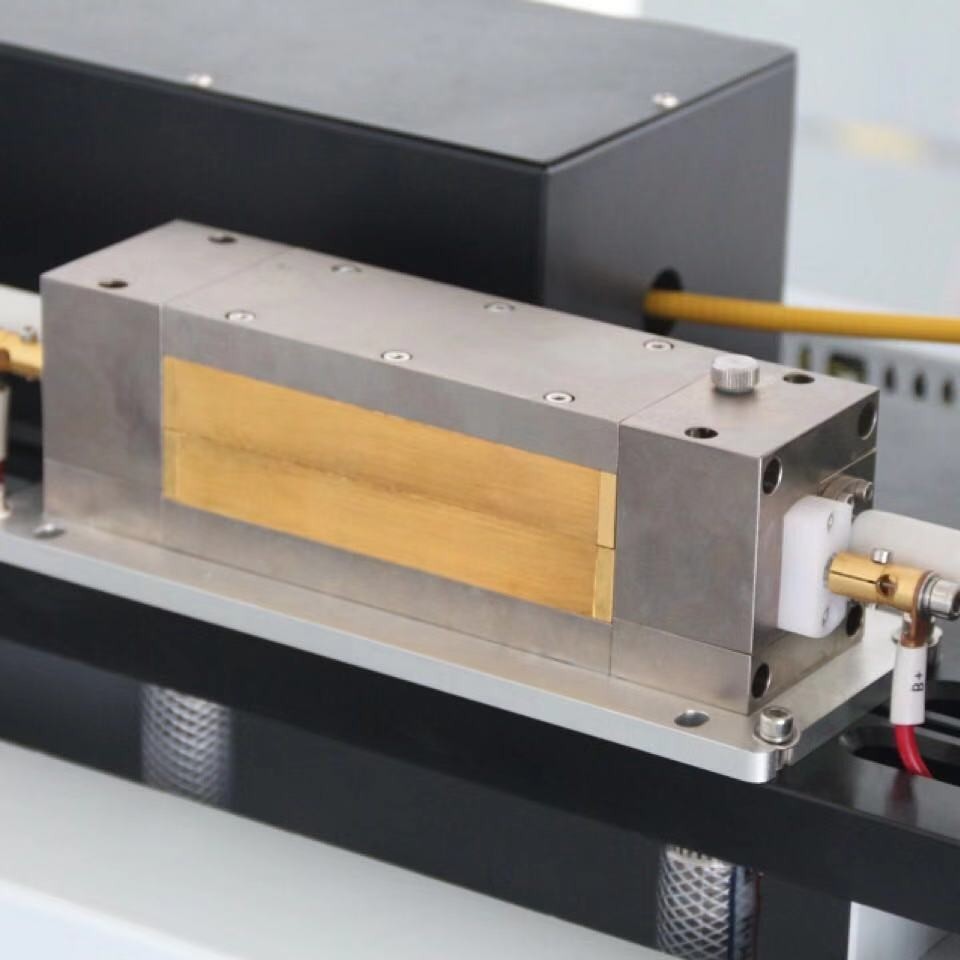

Ceramic cavity

Brand: OPTIC

Origin: China

Use ceramic core with YAG crystal (6*130mm) and xenon lamp,make sure 1064nm laser beam shooting out with continuous and stable power

Xenon lamp: Dayu

Origin: China

Xenon lamp is the the power source of laser,when xenon lamp finished,just need to change a new one and your welder can get back to work.

Dayu xenon lamp is the best quality in China,special for jewelry laser welder

Lifetime: 3,000,000 times

YAG Crystal

1.High gain,High efficiency and HIgh optical quality

2.Low threshold,Low loss at 1.06um

3.Good thermal conductivity and thermal shock characteristics

4.Mechanical strength

5.Material characteristics allow for various modes of operation (CW,pulsed,Q-switched,mode locked and cavity dumped

6.High optical quality

Touch screen

1.It is easy to control the machine

200W jewelry welding machine

200W jewelry welding machine