- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4443*1850*1400mm

-

Weight:

-

5800 KG

-

Product name:

-

Wet Powder Grinder Machine Steel Ball Mill Ore Dressing Mill

-

Feeding Size:

-

25mm

-

Load steel balls weight:

-

1.5Tons

-

Keywords:

-

Gold Ore Ball Mill,Grinding Equipment,Ball Grinder

-

Price:

-

Negotiatable

-

MOQ:

-

1Set

-

Color:

-

As your requirements

-

Main Products:

-

Jaw crusher,Ball mill,Wet pan mill,Spiral chute,Shaking table etc

-

Quality:

-

Excellent

-

Optional Models:

-

600X900,900X1200,900X1800,1200X3000 Ball mill etc

Quick Details

-

Capacity(t/h):

-

0.4-1.2

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Henghong

-

Dimension(L*W*H):

-

4443*1850*1400mm

-

Weight:

-

5800 KG

-

Product name:

-

Wet Powder Grinder Machine Steel Ball Mill Ore Dressing Mill

-

Feeding Size:

-

25mm

-

Load steel balls weight:

-

1.5Tons

-

Keywords:

-

Gold Ore Ball Mill,Grinding Equipment,Ball Grinder

-

Price:

-

Negotiatable

-

MOQ:

-

1Set

-

Color:

-

As your requirements

-

Main Products:

-

Jaw crusher,Ball mill,Wet pan mill,Spiral chute,Shaking table etc

-

Quality:

-

Excellent

-

Optional Models:

-

600X900,900X1200,900X1800,1200X3000 Ball mill etc

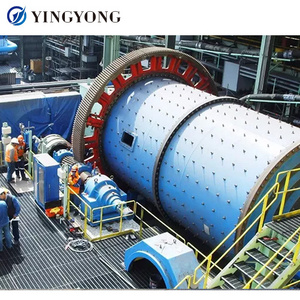

100% Original Factory Sale Crusher Machine Gold Processing Plant Wet Powder Grinder Machine Steel Ball Mill Ore Dressing Mill

Jiangxi Henghong mining machinery is devoting to provide turnkey solution with worldwide clients for mineral processing plant including research, design, manufacture,installation and commissioning, personnel training, after-sale service and management of processing plant. Up to now, we have developed five major product lines: they are mining crushing machine, mining milling machine,mining classifying separator, mining flotation machine and the mining gravity separator. When you find us, you find one best mining machinery manufacturer.

Ball Mill with Widely Applications

Ball mill is

a key equipment to grind the crushed materials,it

widely used in powder-making production line including mineral,cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc. And the ball mill can grind various ores and other materials with dry type and wet type. There are two kinds of ball mill, grid type and overflow type due to different ways of discharging material.

Working Principle

Ball Mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Mainly Characteristics

1. Large ring gear, large side cover and large bearing. The gear hub is large, which can prolong its service life, and adopts high-frequency quenching heat treatment process on the modulated surface; The sprocket adopts high-frequency quenching heat treatment process on the modulated surface.

2. Energy saving: Ball bearings are used instead of slide bearings, which greatly reduces the frictional force, makes starting easier, and saves 10-15% of energy consumption compared with the old ball mill .

3. Large processing capacity: Due to the use of the discharge disc and grate plate of the standard mill, the processing capacity is increased by more than 20% compared with the energy-saving conical ball mill.

4. The mud surface of the discharge port is low, and the mud can pass quickly, which can reduce the excessive grinding of the ore.

5. There are many loaded balls, large and small balls can be loaded, and small balls will not be discharged, and good working conditions can also be formed.

6. The equipment is equipped with Support frame , more easier for clients installation in plant site.

7. The electronic control system has taken protective measures against motor overcurrent, power failure and three power supply imbalances, so as to realize the "worry-free" operation of the ball mill.

2. Energy saving: Ball bearings are used instead of slide bearings, which greatly reduces the frictional force, makes starting easier, and saves 10-15% of energy consumption compared with the old ball mill .

3. Large processing capacity: Due to the use of the discharge disc and grate plate of the standard mill, the processing capacity is increased by more than 20% compared with the energy-saving conical ball mill.

4. The mud surface of the discharge port is low, and the mud can pass quickly, which can reduce the excessive grinding of the ore.

5. There are many loaded balls, large and small balls can be loaded, and small balls will not be discharged, and good working conditions can also be formed.

6. The equipment is equipped with Support frame , more easier for clients installation in plant site.

7. The electronic control system has taken protective measures against motor overcurrent, power failure and three power supply imbalances, so as to realize the "worry-free" operation of the ball mill.

Big Gear

Rotary Body

Steel Balls

Laboratory Ball Mill Introduction

Lab scale ball mill (Laboratory Ball Mill, Small Scale Ball Mill, Mini Ball Mill) is used for making test of grinding materials like ores, chemicals, ceramic materials etc, with capacity from a few kgs to about 1000 kgs. Actually Laboratory ball mill can take care of any pulverizing, milling or grinding job that you can give it. Its multifunction design allows it to handle wet or dry, brittle or fibrous materials. It is a flexible, reliable, compact design, best for laboratory and research use,the laboratory ball mill can be produced by stainless steel, motor 3 phase or single phase,a

ccording to clients' request.

|

Model |

Cylinder Size (mm)

|

|

Revolution of cylinder

|

Weight with balls

|

Feeding Size

|

Capacity

|

Power

|

Weight

|

|

|

|

Diameter

|

Length

|

(r/min)

|

(t)

|

(mm)

|

(t/h)

|

(kw)

|

(kg)

|

|

|

GM0912

|

900

|

1200

|

41.6

|

1.1

|

25

|

0.3~0.9

|

11

|

4210

|

|

|

GM0921

|

900

|

2100

|

41.6

|

1.8

|

25

|

0.6~1.5

|

15

|

6660

|

|

|

GM1224

|

1200

|

2400

|

35.1

|

4

|

0~25

|

1.6~4.1

|

37

|

10020

|

|

|

GM1228

|

1200

|

2800

|

35.1

|

4.6

|

0~25

|

1.9~4.8

|

45

|

10935

|

|

|

GM1232

|

1200

|

3200

|

35.1

|

5.3

|

0~25

|

2.2~5.5

|

45

|

11230

|

|

|

GM1245

|

1200

|

4500

|

30.2

|

6.8

|

0~25

|

3.3~8.2

|

55

|

13210

|

|

|

GM1324

|

1300

|

2400

|

30.2

|

4.5

|

0~25

|

1.5~3.5

|

37

|

10210

|

|

|

GM1328

|

1300

|

2800

|

30.2

|

5.2

|

0~25

|

1.7~4.4

|

45

|

11290

|

|

|

GM1334

|

1300

|

3400

|

30.7

|

6.2

|

0~25

|

2.0~5.2

|

75

|

13111

|

|

|

GM1524

|

1500

|

2400

|

30.7

|

5.8

|

0~25

|

2.3~5.7

|

55

|

15430

|

|

|

GM1530

|

1500

|

3000

|

30.7

|

7.3

|

0~25

|

3.1~7.3

|

75

|

16843

|

|

|

GM1533

|

1500

|

3300

|

30.7

|

8

|

0~25

|

3.5~8.0

|

80

|

17849

|

|

|

GM1536

|

1500

|

3600

|

30.7

|

8.7

|

0~25

|

3.9~8.8

|

80

|

18649

|

|

|

GM1542

|

1500

|

4200

|

30.7

|

10.2

|

0~25

|

4.3~9.4

|

110

|

19330

|

|

|

GM1545

|

1500

|

4500

|

30.7

|

10.9

|

0~25

|

4.8~10.8

|

110

|

20000

|

|

|

GM1557

|

1500

|

5700

|

30.7

|

13.8

|

0~25

|

6.1~14

|

130

|

23597

|

|

|

GM1563

|

1500

|

6300

|

30.7

|

15.3

|

0~25

|

6.5~15

|

155

|

24390

|

|

|

GM1830

|

1800

|

3000

|

25.04

|

10.8

|

0~25

|

2.4~10

|

130

|

24490

|

|

|

GM1834

|

1800

|

3400

|

25.04

|

12.3

|

0~25

|

2.6~11

|

155

|

30390

|

|

|

GM1836

|

1800

|

3600

|

25.04

|

13

|

0~25

|

2.7~12

|

155

|

31600

|

|

|

GM1842

|

1800

|

4200

|

25.04

|

15.2

|

0~25

|

3.3~15

|

180

|

33490

|

|

|

GM1864

|

1800

|

6400

|

25.04

|

23.2

|

0~25

|

5.1~23

|

210

|

42440

|

|

|

GM2130

|

2100

|

3000

|

23.8

|

14.3

|

0~25

|

4.0~30

|

180

|

41960

|

|

|

GM2136

|

2100

|

3600

|

23.8

|

17.1

|

0~25

|

5.0~37

|

180

|

44550

|

|

|

GM2140

|

2100

|

4000

|

23.8

|

19.1

|

0~25

|

5.2~39

|

245

|

46690

|

|

|

GM2145

|

2100

|

4500

|

23.8

|

21.4

|

0~25

|

5.6~42

|

245

|

49230

|

|

|

GM2170

|

2100

|

7000

|

23.8

|

29.2

|

0~25

|

5.9~80

|

380

|

59610

|

|

|

GM2265

|

2200

|

6500

|

21.4

|

34

|

0~25

|

6~67

|

380

|

64800

|

|

|

GM2436

|

2400

|

3600

|

23

|

20.6

|

0~25

|

6.4~81.5

|

280

|

63680

|

|

|

GM2445

|

2400

|

4500

|

23

|

25.1

|

0~25

|

7.9~99.2

|

380

|

72280

|

|

|

GM2464

|

2400

|

6400

|

23

|

36.7

|

0~25

|

11.2~131

|

475

|

86180

|

|

|

GM2736

|

2700

|

3600

|

21.7

|

28.4

|

0~25

|

15~115

|

475

|

88400

|

|

|

GM2742

|

2700

|

4200

|

21.7

|

33.1

|

0~25

|

17.5~135

|

570

|

90420

|

|

Q: 1.What is your machine used for ?

A: Our Ball Mill machine is used for Grinding the Materials Such as Stone, Gold, ilmenite, chromite, pyrite, zircon, rutile, monazite, phosphate, tungsten ore, tin, tantalum, niobium ore etc.

Q: 2.Are you factory or trade company?

A: Yes dear,we are the Professional manufacturer from 1985.So we could give you original factory price than those trade companies.

A: Our Ball Mill machine is used for Grinding the Materials Such as Stone, Gold, ilmenite, chromite, pyrite, zircon, rutile, monazite, phosphate, tungsten ore, tin, tantalum, niobium ore etc.

Q: 2.Are you factory or trade company?

A: Yes dear,we are the Professional manufacturer from 1985.So we could give you original factory price than those trade companies.

We're also warmly welcome your Visiting our factory if you are Coming to China,Please Call at

+86-18870736160

Q: 3.Can I operate it well, if I have no experience?

A: Do not worry! Our machines is designed to use easily.You are welcome to visit our company to be trained here,And we could arrange the engineer to go to your country/company to train your workers directly as your requested and the relative travel cost will be on your account.

Q: 4.Can you send me the video to show how the machine works?

A: Surely.we have made video of every machine,so if you need we can send for you to checking in clearly.

Q: 5. What should I take care when using the machine?

A: Please using the machine in regular and Keeping the machine away from thinner and other chemical liquid.

Q: 6.How about your Service ?

Q: 3.Can I operate it well, if I have no experience?

A: Do not worry! Our machines is designed to use easily.You are welcome to visit our company to be trained here,And we could arrange the engineer to go to your country/company to train your workers directly as your requested and the relative travel cost will be on your account.

Q: 4.Can you send me the video to show how the machine works?

A: Surely.we have made video of every machine,so if you need we can send for you to checking in clearly.

Q: 5. What should I take care when using the machine?

A: Please using the machine in regular and Keeping the machine away from thinner and other chemical liquid.

Q: 6.How about your Service ?

A: All of our machines have one year warranty and Wholelife Technology support to make sure your machine work well.

Q: 7.How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: 8.What about the payment method?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Q:9 What's Information we need from your side ?

Q: 7.How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: 8.What about the payment method?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Q:9 What's Information we need from your side ?

A: What kind of ore do you want to process ? The Capacity per hour do you need ?and the Max feeding size of your material ?

Please Leave us your Inquiry,We will give 100% Positive Responses !

Please Leave us your Inquiry,We will give 100% Positive Responses !

Hot Searches