- Product Details

- {{item.text}}

Quick Details

-

Effective Volume:

-

5-10CMB

-

Dimension(L*W*H):

-

15*10*4m

-

Voltage:

-

Motor Customized

-

Power:

-

15-20KW

-

Weight (KG):

-

10000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

charcoal carbonization stove

-

feature:

-

high capacity,no smoke

-

Raw material:

-

Biomass Wastes

-

Capacity:

-

300-1200KG/H

-

Usage:

-

Biomass Charcoal Directly

-

Advantage:

-

Continuous Working Environment Friendly

-

Carbonization time:

-

20minutes

-

Pre-heating fuel:

-

Coal Gas/LPG/natural gas/

-

Keyword:

-

Recycle Fuel Gas Charcoal Rotary Type Carbonization Machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

NEW product 2023

-

Brand Name:

-

Hongji

-

Effective Volume:

-

5-10CMB

-

Dimension(L*W*H):

-

15*10*4m

-

Voltage:

-

Motor Customized

-

Power:

-

15-20KW

-

Weight (KG):

-

10000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

charcoal carbonization stove

-

feature:

-

high capacity,no smoke

-

Raw material:

-

Biomass Wastes

-

Capacity:

-

300-1200KG/H

-

Usage:

-

Biomass Charcoal Directly

-

Advantage:

-

Continuous Working Environment Friendly

-

Carbonization time:

-

20minutes

-

Pre-heating fuel:

-

Coal Gas/LPG/natural gas/

-

Keyword:

-

Recycle Fuel Gas Charcoal Rotary Type Carbonization Machine

recycle fuel gas charcoal rotary type biochar kiln for making charcoal

Working principle of Recycle Fuel Gas Charcoal Rotary Type Carbonization Machine

Burning the raw material inside of the gasification furnace (as sawdust, shell, Palm shell, husk, straw, wood scrap etc.), the produced flue gas in pipeline within after spray pour, cooling purification, became combustible gas (carbon monoxide, methane, ethane,), as early carbonization of heat, heating and carbonizing the raw material inside of the carbonization furnace(as mechanism core rod, abandoned logs, bark, coconut shell, life garbage,etc.)

When the temperature reached to 300 degrees Celsius, carbonization furnace starting carbonizing of raw materials, producing smoke; flue gas become into a combustible gas after spray pour, cooling purification by the cooling purification system, continue carbonizing, then gasifier stop working.

Technical Specifications of

Charcoal Rotary Type Carbonization Machine

|

# |

Principales parámetros técnicos |

Model-A |

Model-B |

Model- C |

||

|

1 |

Tipo |

Dry Distillation (La destilación seca) |

||||

|

2 |

voltaje |

380 V |

||||

|

3 |

Power (kw) |

Poder |

1.5 + 1.5 + 1.5+5.5+7.5 +2.2 |

3 +3+3 +5.5+7.5 +2.2 |

5.5 + 4 + 4 +5.5+7.5 +2.2 |

|

|

4 |

Capacity ( kg/h ) |

Capacidad |

300-400 |

500-650 |

800 -1 0 00 |

|

|

5 |

Peso de la Máquina Principal |

2 MT |

3.5 MT |

6 MT |

||

|

6 |

Peso de la cadena de producción entera |

6 MT |

8.5 MT |

12 MT |

||

|

7 |

Diámetro de la materia prima |

≤30mm |

||||

|

8 |

trabajando de forma continua |

24 h |

||||

|

9 |

Dimension of the Main Machine (Dia*L) |

Dimensión de la máquina principal |

1.0 x 1 2 m |

1. 2 x 1 2 m |

1.5x12 m |

|

|

10 |

Temperatura interior del horno |

350-500 °C |

||||

|

11 |

Carbonized Pipeline Temperature |

Carbonizado Temperatura Pipeline |

500-700 °C |

|||

|

12 |

El volumen efectivo |

5 m3 |

7 m3 |

10 m3 |

||

The advantagement of Recycle Fuel Gas Charcoal Rotary Type Carbonization Machine

1.None stoping,working for 24 hours

2.Large capacity,one day can reach to 7.2 tons

3.Environmental protection,burn the furnace smoke itself,so no smoke go out

4.Energy saving,burn smoke as power.

5.Make sawdust ,rice hush,coconut shell,,,ect into charcoal timely.

6.Sawdust carbonization furnace energy is recycle using.

Raw material&charcoal powder

Raw materia :sawdust, shell, Palm shell, husk, straw, wood scrap.

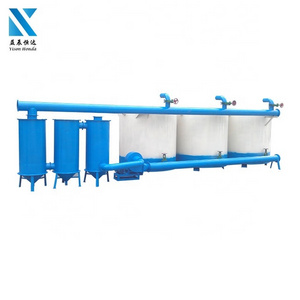

This machine is equipped with: Auto-feeding Conveyor,Dust-Removal Device,Gas cleanersystem, PLC touchscreen manual automatic dual-use electric control cabinet, Cooling and Discharging Conveyor,Carbonization furnace and other equipments.

There are three kind of burner: LPG/Natural gas, Gasifier(burning coal),