- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

1.5kw

-

Weight:

-

130 KG

-

Dimension(L*W*H):

-

75*85*110cm

-

Year:

-

2024

-

Application:

-

Root Vegetables

-

Product name:

-

Multifunctional Fruit Processing Machine

-

Function:

-

Multifunctional

-

Name:

-

Electric Food Fruits Dehydrators

-

Keywords:

-

Vegetable Fruits Cleaning Washing Line

-

Usage:

-

Commercial Usage

-

Capacity:

-

500kg/h

-

Suitable for:

-

Fruit Processing Industry

-

After-sales Service Provided:

-

Engineers

-

Material:

-

304 Stainless Steel

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RunXiang

-

Voltage:

-

380v

-

Power:

-

1.5kw

-

Weight:

-

130 KG

-

Dimension(L*W*H):

-

75*85*110cm

-

Year:

-

2024

-

Application:

-

Root Vegetables

-

Product name:

-

Multifunctional Fruit Processing Machine

-

Function:

-

Multifunctional

-

Name:

-

Electric Food Fruits Dehydrators

-

Keywords:

-

Vegetable Fruits Cleaning Washing Line

-

Usage:

-

Commercial Usage

-

Capacity:

-

500kg/h

-

Suitable for:

-

Fruit Processing Industry

-

After-sales Service Provided:

-

Engineers

-

Material:

-

304 Stainless Steel

Product Description

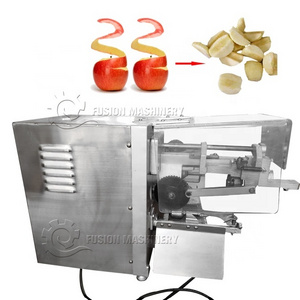

The working principle of the corer beater is to break the fruit into small pieces through rotational motion and friction, while removing the core. Specifically, a corer beater usually consists of one or more rotating blades and a fruit and vegetable container. As the blade rotates, it interacts with the container wall, creating friction and crushing effects so that the fruit is gradually cut into small pieces. At the same time, due to the design and movement trajectory of the blade, the fruit core will be separated from the pulp and collected to a specific location.

The motor is driven by the V-belt to rotate the rotor component at high speed. The fruit is transported from the feeding port into the machine, and the feeding paddles spirally transport the material to the beating rod. Under the action of the beating rod, the material is mashed. Due to the action of centrifugal force, the material is The juice and meat enter the next process through the sieve holes on the screen, and the core is discharged from the slag outlet through the slag pulp leaves to achieve separation.

Operation and precautions:

Before starting the machine, first check whether the connection between the parts of the rotor component is firm and reliable, and whether the motor steering is consistent with the sign, and then add grease to the bearings at both ends.

Turn the handwheel clockwise and lock the front cover of the cylinder before driving; then add the material evenly without impact. Depending on the specific conditions of the slag and slurry, the helix angle of the scraper and the gap between the scraper and the screen should be appropriately adjusted to ensure that the juice content of the slag meets the process requirements. Stop: Turn the handwheel counterclockwise. After the motor stops rotating, pull out the main brake.

★Do not open the front cover of the cylinder when the rotor has not stopped rotating.

★After each shift, it should be cleaned and maintained once to prevent the material from fermenting and deteriorating in the machine and the lubricating part from losing oil. When cleaning, open the front cover of the cylinder and unscrew the tightening screw at one end of the spline to easily pull out the rotor component and the screen can be taken out directly.

Detailed Images

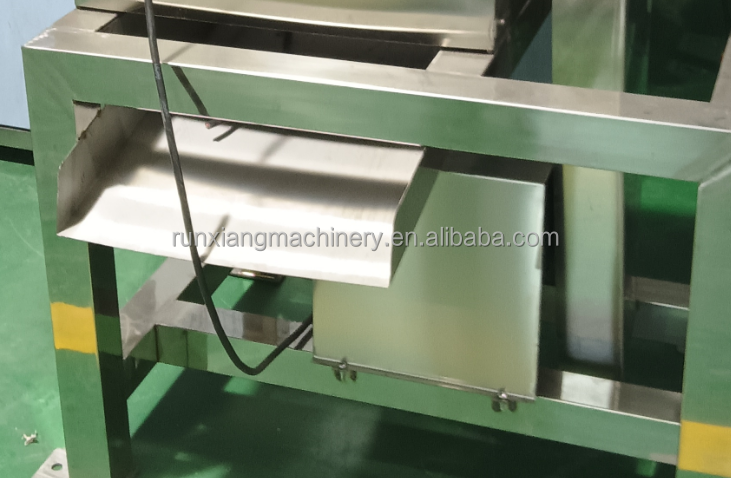

The whole machine uses food-grade stainless steel. The equipment has a long service life, takes up little space, has a beautiful structure and is easy to maintain.

Automatic nuclear and plasma separation without clogging

Smooth feeding, internal filter screen

Pulp and slag separation, high pulp extraction rate

Inlet

When the fruit is in the feed port, the oil-feeding blades spirally convey the material to the beating rod for core removal and pulping, and the core pulp is automatically separated.

Applicable material display:

Parameter information:

|

Model

|

Capacity(kg)

|

Power(kw)

|

Size(mm)

|

Weight(kg)

|

Material

|

|

RX-500

|

500

|

1.5

|

750*850*1100

|

130

|

SS304

|

|

RX-1000

|

1000

|

3

|

1200x800x1500

|

160

|

SS304

|

Best Selling

Company Introduction

Hot Searches