Warranty & After-Sales Service

1. Ordinary equipment the first 14 months, free charge spare parts.

2. luxury equipment the first 24 months, free charge spare parts.

3. Lifetime warranty.

4. Engineers are available to be serviced overseas.

5. Provide design and technical support

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

3.5KW

-

Dimension(L*W*H):

-

1950*2100*2250mm

-

Weight:

-

1650 KG

-

Machinery Function:

-

Toast production line

-

Output product name:

-

Toast production line

-

Product name:

-

Cheap price Toast machine White bread making production line

-

Material:

-

Stainless Steel 304

-

Application:

-

Bread Bakery Machine

-

Function:

-

Full complete bakery machine

-

Advantage:

-

Easy Operation High Efficiency

-

Temperature Range:

-

Room Temperature~300

-

Suitable for:

-

baguette bread

-

Capacity:

-

100~200kg/h

-

Type:

-

Automatic

-

MOQ:

-

1 Set

Quick Details

-

Brand Name:

-

haidier

-

Place of Origin:

-

Hebei,China

-

Voltage:

-

380/415V

-

Power:

-

3.5KW

-

Dimension(L*W*H):

-

1950*2100*2250mm

-

Weight:

-

1650 KG

-

Machinery Function:

-

Toast production line

-

Output product name:

-

Toast production line

-

Product name:

-

Cheap price Toast machine White bread making production line

-

Material:

-

Stainless Steel 304

-

Application:

-

Bread Bakery Machine

-

Function:

-

Full complete bakery machine

-

Advantage:

-

Easy Operation High Efficiency

-

Temperature Range:

-

Room Temperature~300

-

Suitable for:

-

baguette bread

-

Capacity:

-

100~200kg/h

-

Type:

-

Automatic

-

MOQ:

-

1 Set

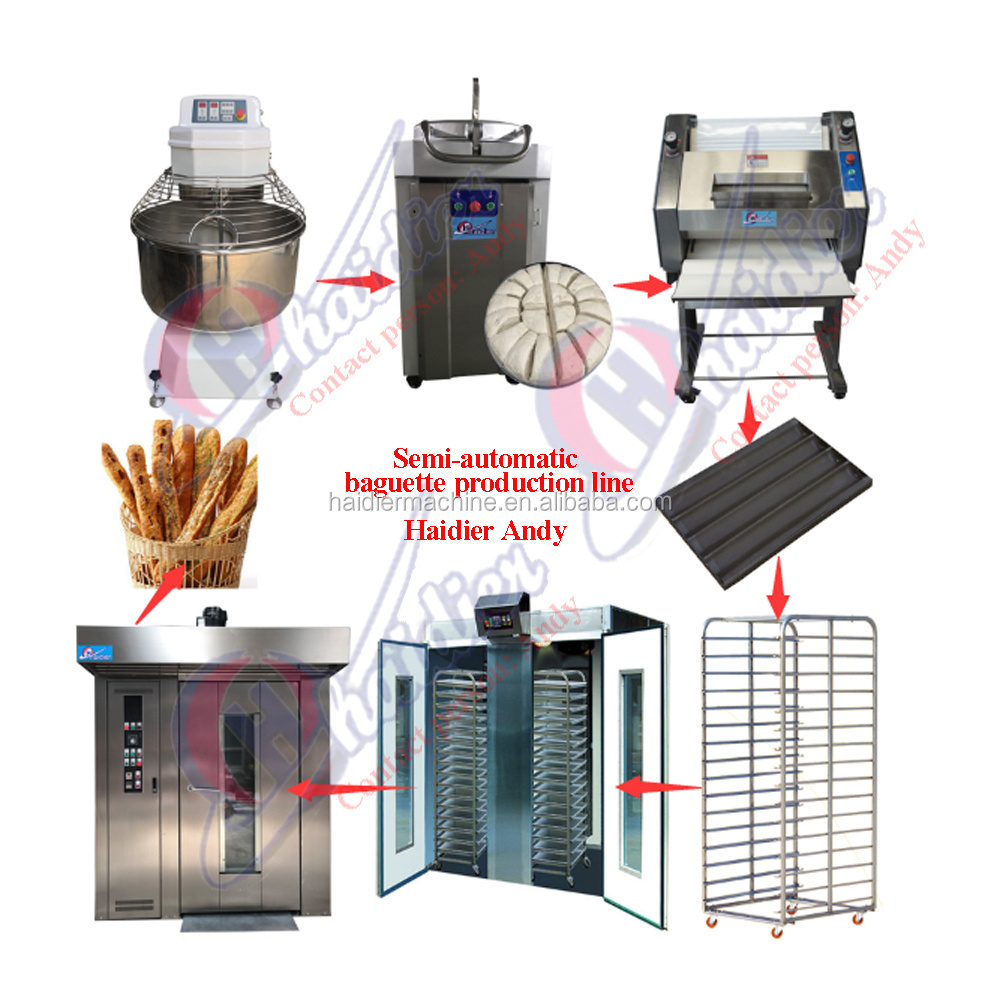

Product Description

Baguette bread production line include:

1.Sprial Dough mixer

2. Hydraulic dough divider

3. Baguette dough moulder

4. Dough Proofer

5. Rotary Oven

6. Baking trolley and tray

4. Dough Proofer

5. Rotary Oven

6. Baking trolley and tray

Details Images

Step one: Self-tipping Dough mixer

First Step, one dough mixer to mixing the flour,Haidier factory have different capacity dough mixer,and we are also can offer you dough mixer with removable bowl and Self-tipping dough mixer for you.

|

Model

|

Capacity(kg)

|

|

External Dimension

W×D×H(mm)

|

Power

(Kw)

|

Weight

(kg)

|

Speed

(Round/Min)

|

|

|

|

Dough

|

Flour

|

|

|

|

|

|

|

HDR-25

|

25

|

15

|

490×820×1090

|

2.2

|

180

|

115/230

|

|

|

HDR-50

|

50

|

30

|

590×1080×1270

|

4.5

|

260

|

0.5

|

|

|

HDR-100

|

100

|

60

|

720×1160×1300

|

5.5

|

420

|

115/230

|

|

|

HDR-120

|

120

|

80

|

800×1350×1320

|

9.5

|

560

|

110/220

|

|

|

HDR-160

|

160

|

100

|

925×1550×1400

|

11

|

850

|

110/220

|

|

|

HDR-200

|

200

|

125

|

990×1560×1500

|

12.5

|

920

|

110/220

|

|

Step Two: HYDRAULIC DOUGH DIVIDER

Second, one dough divider to dividing the dough, Haidier dough divider can divide 20pcs per time,dough weight is 135-800g or 200-1000g,Our machine imporvev efficiency and divider the dough uniform

|

Model

|

Dimension

|

Power

(Kw)

|

Weight Range ( g )

|

Divisions( pcs)

|

Max Dough Capacity

|

|

|

L*W*H (mm)

|

|

|

|

|

|

HDR-20

|

680*590*930

|

0.75

|

135-800g

|

20

|

16000

|

|

HDR-20

|

680*590*930

|

0.75

|

200g-1000g

|

20

|

16000

|

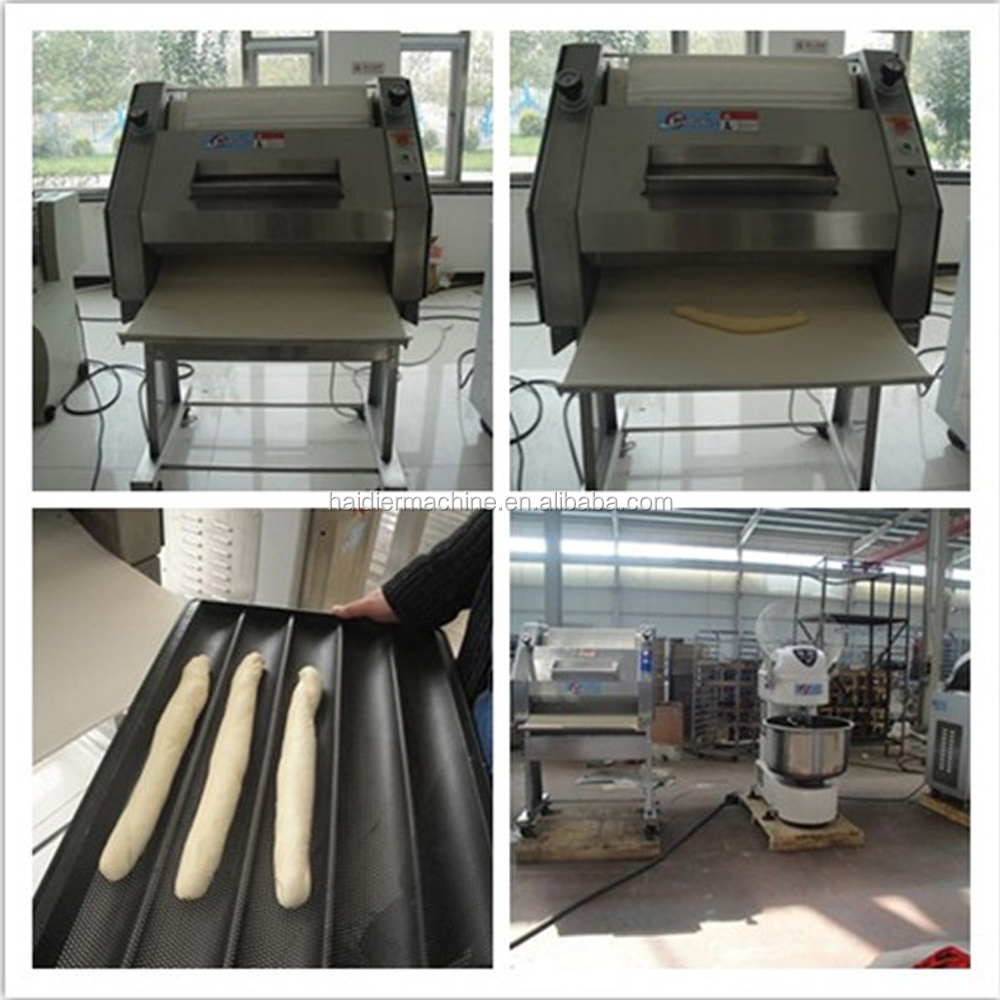

Step Three: Baguette dough moulder

Third Step,one baguette dough moulder to moulding the dough, Haidier dough moulder is suitable for all kinds of bread roll ect,

|

Name

|

Model

|

Power (Kw)

|

Outer Dim(mm)

|

Weight (Kg)

|

|

French Baguettes Moulder

|

HDR-750

|

0.375

|

970*680*1600

|

175

|

Step Four: Dough Proofer

Fourth step: one proofer to fermentating the dough,Haidier with Big proofing room,can contain 2 trolleys 4 trolleys 6 trolleys and 8 trolleys ect,meet the fermentation needs

|

Model

|

Power(Kw)

|

Outer Dim(mm)

|

Weight(Kg)

|

Capacity

|

Note

|

|

HDR-32

|

2

|

1120 *850*2000

|

150

|

32 Trays

|

One door

|

|

HDR-40

|

2

|

730*1010*2100

|

160

|

40 Trays

|

one door

|

|

HDR-4/32

|

4.5

|

1850*1900*2180

|

220

|

4 Racks

|

Stainless Steel

|

|

|

|

|

|

(32Tray*4)

|

|

|

HDR-6/32

|

6

|

2000*2200*2100

|

260

|

6 Racks

|

Stainless Steel

|

|

|

|

|

|

(32Tray*6)

|

|

|

HDR-8/32

|

9

|

2300*2900*2180

|

300

|

8 Racks

|

Stainless Steel

|

|

|

|

|

|

(32Tray*8)

|

|

Step Five: Baking trolley and trays

400*600mm baking trolley or 600*800mm baking trolley,all kinds of loaf tin,250g 450g 600g 750g 900g 1000g 1200g ect

Step Six: Rotary Oven baking the bread

Six step: one oven to baking the bread,Haidier with rotary oven,deck oven.As for rotary oven,we have electric diesel and gas oven,16 trays 32 trays and 64 trays,high efficiency,baking bread evenly

|

Model

|

Tray Size (mm)

|

Power ( KW)

|

Weight( Kg)

|

Baking space (m2)

|

Overal Dim(mm)

|

|

|

|

Electric oven

|

|

|

|

|

HDR-4616

|

400*600/16

|

32

|

1050

|

4.5

|

1720*1880*2150

|

|

HDR-5616

|

600×500/16

|

36

|

1200

|

5.4

|

1780*1810*2150

|

|

|

650×450/16

|

|

|

|

|

|

HDR-4632

|

400*600/32

|

45

|

1650

|

8.5

|

1950*2100*2250

|

|

|

800*600/16

|

|

|

|

|

|

HDR-5732

|

762×465/32

|

65

|

2000

|

12.6

|

2180*2130*2250

|

|

|

720×460/32

|

|

|

|

|

|

HDR-4664

|

400*600/64

|

76

|

2650

|

15

|

2130*3100*2350

|

|

|

800*600/32

|

|

|

|

|

|

HDR-5832

|

400×950/32 400*900/32

|

75

|

2600

|

15.4

|

2300*2230*2350

|

|

|

500×800/32 1000×800/16

|

|

|

|

|

After Baking toast bread, DELICIOUS!!!

Maybe you are also need other parts as follow:

Worktable

Worktable for bakery shop and factory, it is help you have enough speac to operate make the bread

Cooling wire rack

After baking the bread,it is need a place to make the bread cool.

Refrigerator

it is a very important for making the bread, because it is can

guarantee food fresh

Recommend Products

Packing&Shipping

1, mechanical surface coated with preservative solution (to protect stainless steel)

2, the plastic cushion packing machine (prevent bump)

3, plastic film packaging (to prevent ventilation)

4, wooden case/frame packaging (easy to transport)

5, tie the bandage outside of the wooden case (reinforcement overall)

After Sales Service

About after sales service

Hot Searches