- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Fscut

-

Cutting Area:

-

600*600mm

-

Cutting Thickness:

-

1-40mm

-

Control Software:

-

Cycput

-

Place of Origin:

-

China

-

Brand Name:

-

Jowuey

-

Weight (KG):

-

1000 KG

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

Keyword:

-

Fiber Laser Cutting Machiens

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

680mm/sec

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Fscut

-

Cutting Area:

-

600*600mm

-

Cutting Thickness:

-

1-40mm

-

Control Software:

-

Cycput

-

Place of Origin:

-

China

-

Brand Name:

-

Jowuey

-

Weight (KG):

-

1000 KG

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

Keyword:

-

Fiber Laser Cutting Machiens

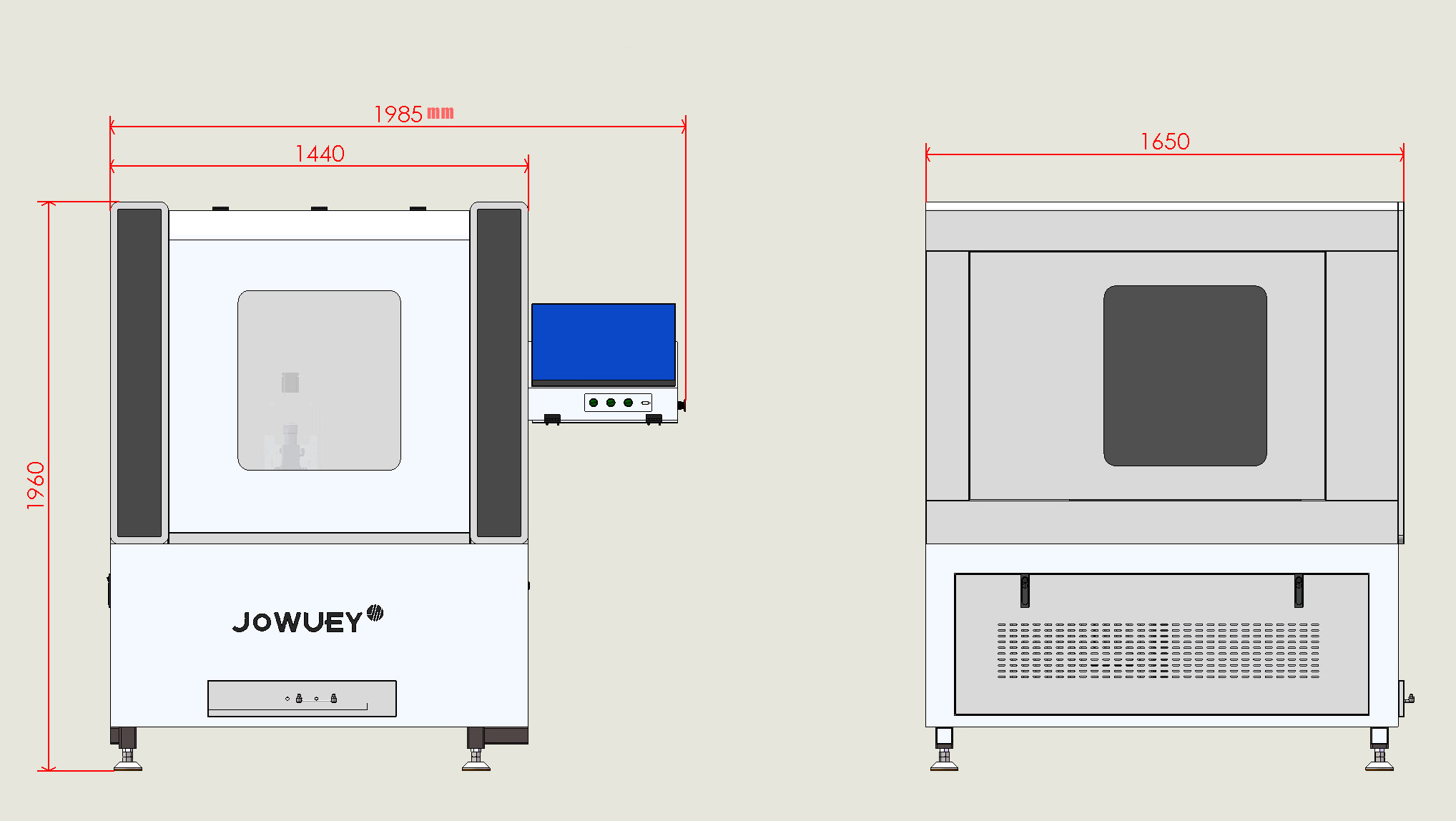

JOWUEY 6060M7 Fiber Laser Cutting Machine

Product Paramenters

To learn more about the rule parameters or to customize the size of the machine Please contact the online customer service

|

Working area

|

600*600mm

|

|

Power

|

1000w 1500w 2000w 3000w

|

|

Cutting thickness

|

1-40mm

|

|

X/Y axis positioning accuracy

|

±0.05mm/m

|

|

X/Y axis repeat positioning accuracy

|

±0.03mm

|

|

Maximum positioning speed

|

60m/min

|

|

Maximum acceleration

|

60m/min

|

|

Maximum load on work surface

|

700kg

|

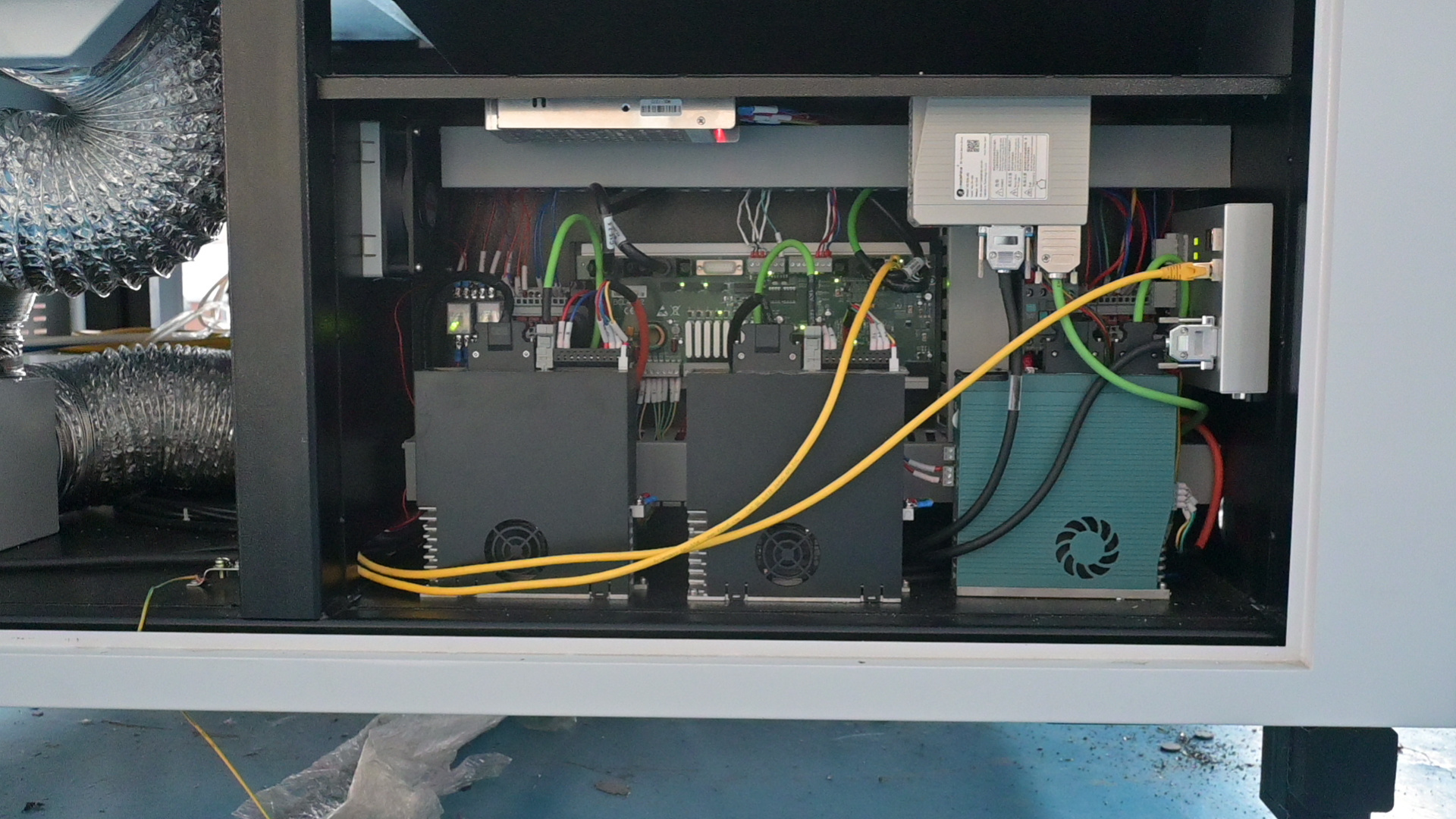

Details Images

Electrical box

The wiring of our electric box is neatly planned,and it is easy to identify by using different colors

Dorna servo motor

Applicable power 0.1kw-3kw, up to 6000RPM, up to 3.5 times overload capacity, 17bit single-turn absolute value magnetic encoder, equipped with 23bit support, ip67 high protection capability

MAX Laser

Main features:

(1) High-quality laser output

(2) High power and high efficiency

(3) High reliability and long life

(4) Compact, sturdy packaging

(5) Extended programming interface

FScut controller

A high-performance open-loop laser control system, widely used in the field of metal and non-metal laser cutting, it can easily produce and process advertising characters, supports perforation cutting of medium-sized plates, and comes with simple layout, improving plate utilization and reducing processing time during the cutting process. Deceleration and lifting to increase cutting speed

Laser head

Auto-focusing fiber cutting head. This product has a built-in motor drive unit that drives the focusing lens to automatically change its position within a 24mm range through a linear mechanism. Users can set the continuous focus through the program to complete rapid perforation of thick plates and automatic cutting of plates of different thicknesses and materials.

XY axis ball screw transmission

XY axis ball screw drive to improve accuracy

Water chiller

Precision water chiller, the temperature can becontrolled +0.3C, it has two functions ofconstant temperature and intelligent temperatureregulation.

Blade table

The contact surface between the blade table and the cutting material can be reduced as much as possible, and the blade density can be adjusted according to the size of the material. This platform is suitable for the processing of arcylic and other plates, reducing the contact surface between the material and the platform, solving the diffuse reflection caused by the laser hitting the platform after cutting through the material, and leaving traces on the lower part of the material to achieve a better cutting effect.

Application Materials

it is suitable for engraving cutting wood, plastic, MDF, glass, leather, rubber, laminate and other non-metallic materials.(For more materials and finished products, please contact online customer service)

Our Advantages

Configuration

1.Working area 600x600 mm

2.MAX laser

3.FSCUT control system

4.DORNA servo motor

5.

XY axis ball screw transmission

6. S&A Chiller

Advantages

1. The tabletop and machine tool are separated to solve the problem of machine tool deformation after long working hours.

2. Finishing the tabletop solves the problem of uneven tabletops, improves cutting accuracy during work, and extends service life.

3. The guide rail positioning device is generally found in high-power segments above 3000 watts, which improves the accuracy of the equipment.

4. The smoking on the X-axis + the smoking device under the funnel smoke together, which greatly improves the smoking effect and reduces the pollution of the equipment by smoke and dust.

5. The beam material is 6063-T5 high-strength aluminum profile, which reduces the weight of the beam and increases the strength of the beam.

7. Cross beam fixing unit, pin-type seated fixing method to prevent diagonal deviation during long-term work.

Our Service

What kind of support you can get from LASER MAX?

♦

Warranty:

We promise to keep products that are manufactured and shipped according to a formal contract, and we guarantee that every repaired machine will perform well if used correctly. You have the right to repair or replace an item in the warranty period if you have a material or technical problem. We will charge maintenance in normal cases. It will be free if the machine has special problems.

♦After sale services:

1.12 months quality guarantee, the machine with main parts (not including consumables) will be changed for free if there is any problem during the warranty period.

2. Free training in our plant.

3. We will provide the Consumable Parts at an agency price when replacement is required.

4. Can help you solve problems online or by email in 24 hours, free technical support.

Hot Searches