- Product Details

- {{item.text}}

Quick Details

-

Height:

-

From 10M-100M or according to client's requirement

-

Suit for:

-

Electric Power Transmission and Distribution

-

Shape:

-

Polygonal or Conical

-

Power Capacity:

-

10kV to 500kV

-

Tolerance of the dimension:

-

According to client's requirement

-

Surface treatment:

-

Hot-dip-galvanized following ASTM123, or client's requirement

-

Joint of Poles:

-

Slip joint, flanged connected

-

Standard:

-

ISO9001:2008

-

Length of per section:

-

Within 13M once forming

-

Welding Standard:

-

AWS(American Welding Society)D 1.1

Quick Details

-

Brand Name:

-

OEM

-

Model Number:

-

30M

-

Place of Origin:

-

Shandong, China

-

Height:

-

From 10M-100M or according to client's requirement

-

Suit for:

-

Electric Power Transmission and Distribution

-

Shape:

-

Polygonal or Conical

-

Power Capacity:

-

10kV to 500kV

-

Tolerance of the dimension:

-

According to client's requirement

-

Surface treatment:

-

Hot-dip-galvanized following ASTM123, or client's requirement

-

Joint of Poles:

-

Slip joint, flanged connected

-

Standard:

-

ISO9001:2008

-

Length of per section:

-

Within 13M once forming

-

Welding Standard:

-

AWS(American Welding Society)D 1.1

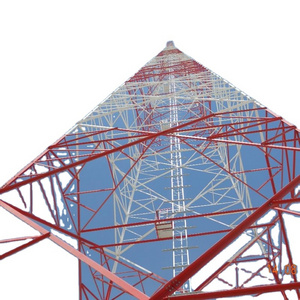

New design professional microwave antenna mast and communication tower

Product Description

| Height | From 10M-100M or according to client’s requirement | |||||

| Suit for | Electric Power Transmission and Distribution | |||||

| Shape | Polygonal or Conical | |||||

| Material | Normally Q235B/A36,Yeild Strength≥235MPa | |||||

| Q345B/A572,Yeild Strength≥345MPa | ||||||

| As well as Hot Rolled coil from ASTM572, GR65,GR50,SS400 | ||||||

| Power Capacity | 10kV to 500kV | |||||

| Tolerance of the dimension | According to client’s requirement | |||||

| Surface treatment | Hot-dip-galvanized following ASTM123, or any other standard by client’s requirement | |||||

| Joint of Poles | Slip joint, flanged connected | |||||

| Standard | ISO9001:2008 | |||||

| Length of per section | Within 13M once forming | |||||

| Welding Standard | AWS(American Welding Society)D 1.1 | |||||

| Production Process | Raw material test-cutting-bending-welding-dimension verify-flange welding-hole drilling-sample assemble-surface clean-galvanization or power coating /painting-recalibration-packages | |||||

| Packages | Packing with plastic paper or according to client’s requirement | |||||

| Life Period | More than 25 years, it is according to installing environment | |||||

Hot Searches