- Product Details

- {{item.text}}

Quick Details

-

Name:

-

polished finishing carbide buttons

-

Color:

-

Gray

-

Material:

-

100% Virgin cemented carbide

-

Surface:

-

Sandblasting or Tumbling are available

-

Diameter:

-

12 to 16.3mm

-

ADWords:

-

Carbide Mining Buttons

-

Brand name:

-

ZZJG or OEM

-

Place of origin:

-

China

-

Sample:

-

Available

-

Certificates:

-

ISO 9001:2008,ISO 14001:2004

Quick Details

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

ZZJG or OEM

-

Model Number:

-

Carbide Buttons

-

Name:

-

polished finishing carbide buttons

-

Color:

-

Gray

-

Material:

-

100% Virgin cemented carbide

-

Surface:

-

Sandblasting or Tumbling are available

-

Diameter:

-

12 to 16.3mm

-

ADWords:

-

Carbide Mining Buttons

-

Brand name:

-

ZZJG or OEM

-

Place of origin:

-

China

-

Sample:

-

Available

-

Certificates:

-

ISO 9001:2008,ISO 14001:2004

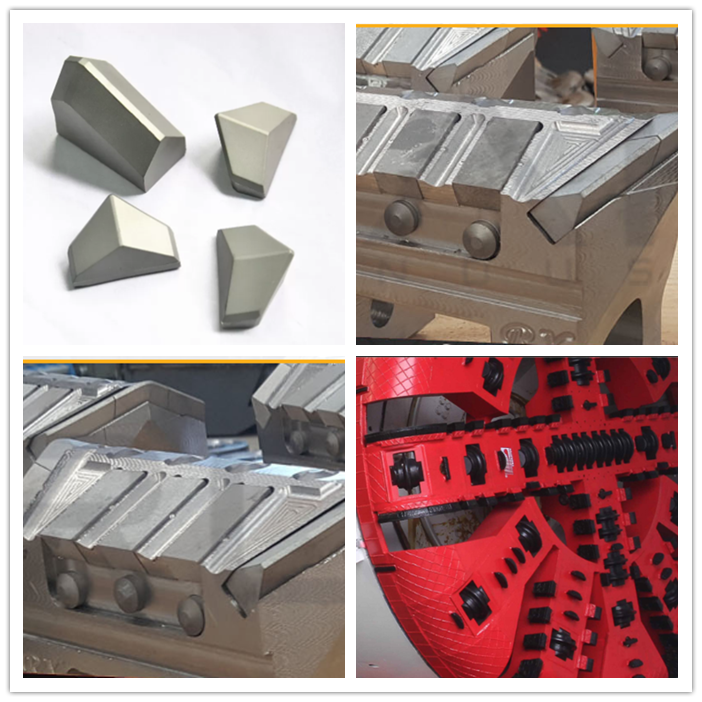

Suppy tungsten carbide inserts carbide tips for TBM cutter( Tunnel Boring Machines) TBM PARTS

Main Details:

1.Excellent Hardness: 86~93 HRA, which equal to 68~81HRC;

2.Excellent Hot Working Performance: Hardness could be remained at 60 HRC under 900~1000 ℃;

3.Resistance Wear: Some grades can outwear hardened steel by over 100 times

4.Resistance Corrosion: Grades with Nickel and Chromium binders are very resistant to acidic solutions

5.Impact Resistance: Tungsten cemented carbides are surprisingly tough considering their high hardness.

All carbide bars provided by us are include all these properties, which is suitable for cutting tools.

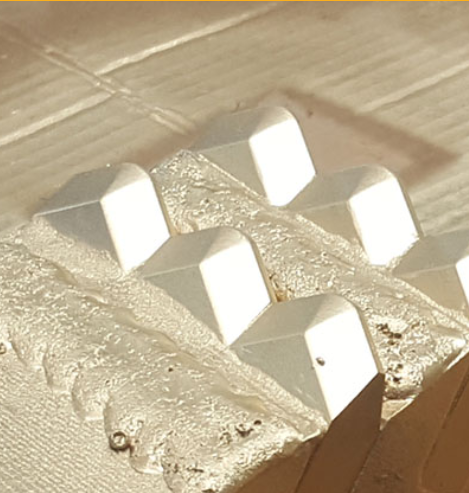

Pictures of polished carbide buttons:

Specifications of polished finishing carbide buttons:

Grade details for your reference:

|

Grade |

Density g/cm³ |

Hardness HRA |

TRS N/mm² |

Particle size |

ISO Code |

Applications |

| YG4C | 15.00 | 89.5 | 1600 | coarse | K20 | Suitable for making geological prospecting drill bits and mining inserts of light-duty electrical drill bits for drilling soft rock, coal formations and drill bits for drilling un-silicated rock formations. |

| JK05 | 15.00 | 89.5 | 2500 | coarse | K20 | Mainly used for making medium and small sized cemented carbide buttons of tricone bits and other drilling bits for drilling soft & medium hard rock formations, also used for making carbide inserts of other drill bits. |

| JK03 | 14.90 | 90.1 | 2600 | coarse | K20 | |

| JK06 | 14.90 | 91.0 | 2450 | medium | K20 | |

| YG8C | 14.75 | 89.0 | 2000 | coarse | K30 | Mainly used for making cemented carbide buttons of tricone bits and other drilling bits for drilling medium hard & hard rock formations, also used for making cemented carbide inserts of other drill bits. |

| JK08 | 14.70 | 89.0 | 2400 | coarse | K30 | |

| JK09 | 14.50 | 88.0 | 2600 | coarse | K30 | |

| JK10 | 14.45 | 88.5 | 2600 | medium | K40 | Suitable for carbide inserts of heavy-duty rock drilling tools for drilling hard & super hard rock formations, also used for making tricone bits and other button bits. |

| JK20 | 14.40 | 87.0 | 2700 | coarse | K40 | |

| JK25 | 14.45 | 87.0 | 2700 | coarse | K40 | |

| YG11C | 14.40 | 87.8 | 2700 | coarse | K40 | With super toughness and corresponding wear resistance, suitable for carbide inserts of heavy-duty rock drilling tools and DTH drilling bits for drilling hard and super hard rock formations, also used for other cemented carbide buttons bits. |

| YG13C | 14.20 | 86.0 | 2600 | coarse | K40 | |

| JL10B | 14.80 | 88.5 | 3000 | super coarse | K30 | Ultra coarse grain, with super toughness and corresponding wer resistance, suitable for carbide inserts of heavy-duty rock drilling tools and DTH drilling bits for drilling hard and super hard rock formations, also used for other cemented carbide buttons bits. |

| JL15B | 14.50 | 86.0 | 3000 | super coarse | K20 |

| >>>> Welcome to contact us for more details! welcome to contact us for more details |

Tungsten carbide mining tools produced by powder metallurgy method, the key to its process control is the chemical composition of the material and the mixture was prepared, pressed molding, sintering and deep processing and other preparation process parameters:

1.

Preparation of starting material (WC focus quality): As the WC raw material and quality control of the use of different levels of quality may fluctuate, resulting in adverse effects on microstructure. We only use 100% virgin material and no recycling at all.

2.

Pressing: pressing is an important process of the roller mill. With Advanced thousands of oil hydraulic press machine and automatic press machine, We can guarantee delivery on time.

3.

Sintering: to determine the final quality of the production processes, we use of advanced low-pressure sintering technology, HIP sintering technology can greatly improve the performance of our goods.