Silicon Carbide Pipe is made of silicon carbide as the main raw material, adding a variety of chemical wear-resistant raw materials and anti-oxidant, effectively improving the wear resistance of the product, using SiO2 micro powder as the high-temperature bonding phase, a high-performance silicon carbide products by high-temperature firing.

- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

Customized

-

CrO Content (%):

-

0.002%

-

SiC Content (%):

-

90-98%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RONGSHENG

-

Product name:

-

silicon carbide kiln furniture

-

Density:

-

3.02g/cm3

-

Characteristic:

-

Long Service Life

-

Feature:

-

High Temperature Resistance

-

Application:

-

electric power, steel plant slag flushing trench

-

Sic Content:

-

98% or Customized

-

Working Temperature:

-

1800 Degree Celsius

-

Color:

-

BLACK GREY

-

Certificate:

-

CE,ISO9001

-

Raw material:

-

Silicon Carbide (SiC)

Quick Details

-

SiO2 Content (%):

-

International Standard

-

Al2O3 Content (%):

-

Customized

-

MgO Content (%):

-

0.18%

-

CaO Content (%):

-

Customized

-

CrO Content (%):

-

0.002%

-

SiC Content (%):

-

90-98%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RONGSHENG

-

Product name:

-

silicon carbide kiln furniture

-

Density:

-

3.02g/cm3

-

Characteristic:

-

Long Service Life

-

Feature:

-

High Temperature Resistance

-

Application:

-

electric power, steel plant slag flushing trench

-

Sic Content:

-

98% or Customized

-

Working Temperature:

-

1800 Degree Celsius

-

Color:

-

BLACK GREY

-

Certificate:

-

CE,ISO9001

-

Raw material:

-

Silicon Carbide (SiC)

Product Description

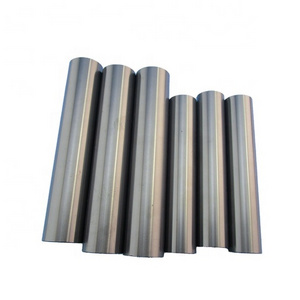

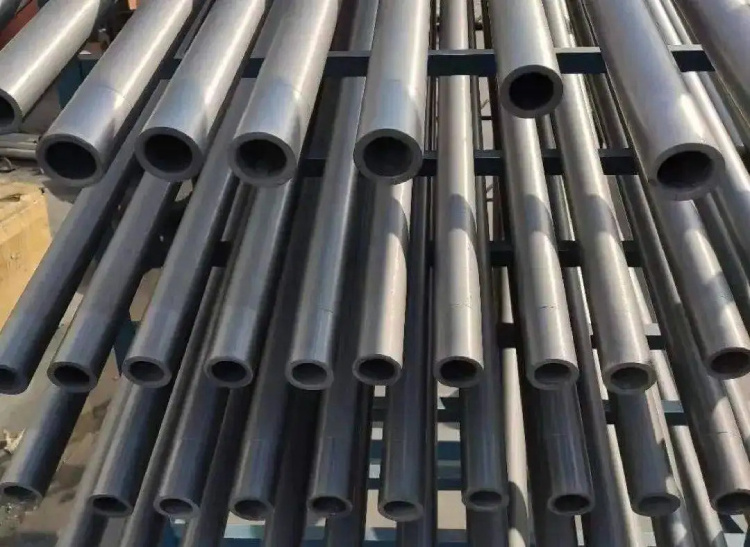

Silicon Carbide Pipe

Silicon Carbide Tube

Silicon carbide tube has the advantages of high strength, high hardness, good wear resistance, high temperature resistance,

corrosion resistance, good thermal shock resistance, high thermal conductivity and good oxidation resistance.

matic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Silicon Carbide Beam

Silicon carbide beam is widely used in ceramic high temperature kiln, steel mill quenching furnace, mine material classification cyclone, large boiler and power plant desulfurization and dust removal equipment, coal slag pneumatic conveying equipment, high-tech and military equipment. Applied in machinery, metallurgy, electronics, chemical industry, iron and steel, ceramics, paper making, mineral processing, nuclear industry, national defense and so on.

Advantage

1. Dimensional stability at high temperature, anti-deformation, high high temperature strength

2. Thermal shock resistance, wear resistance and corrosion resistance

3. Anti-oxidation and erosion resistance

Can be widely used in: electric power, steel mill slag flushing groove, coal chemical industry, mining, transmission pipeline.

Application

Specification

|

Shape

|

PIPE

|

|

Material

|

Silicon Carbide (SiC)

|

|

SiO2 Content (%)

|

International Standard

|

|

Al2O3 Content (%)

|

Customized

|

|

MgO Content (%)

|

0.18%

|

|

CaO Content (%)

|

Customized

|

|

Refractoriness (Degree)

|

Common (1580°< Refractoriness< 1770°)

|

|

CrO Content (%)

|

0.002%

|

|

SiC Content (%)

|

90-98%

|

|

Brand Name

|

RONGSHENG

|

|

Processing Service

|

Bending, Cutting, Moulding

|

|

Product name

|

silicon carbide kiln furniture

|

|

Density

|

3.02g/cm3

|

|

Characteristic

|

Long Service Life

|

|

Feature

|

High Temperature Resistance

|

|

Application

|

electric power, steel plant slag flushing trench

|

|

Sic Content

|

98% or Customized

|

|

Working Temperature

|

1800 Degree Celsius

|

|

Color

|

BLACK GREY

|

|

Certificate

|

CE,ISO9001

|

|

Raw material

|

Silicon Carbide (SiC)

|

|

Technical Performance

|

Bulk Density

|

Abrasion Resistance

|

Moh's Hardness

|

CCS

|

|

|

g/cm³

|

%

|

MPa

|

Mpa

|

|

Silicon Carbide Tubes

|

2.7

|

1.66

|

>9.0

|

21.2

|

Packing & Delivery

Hot Searches