- Product Details

- {{item.text}}

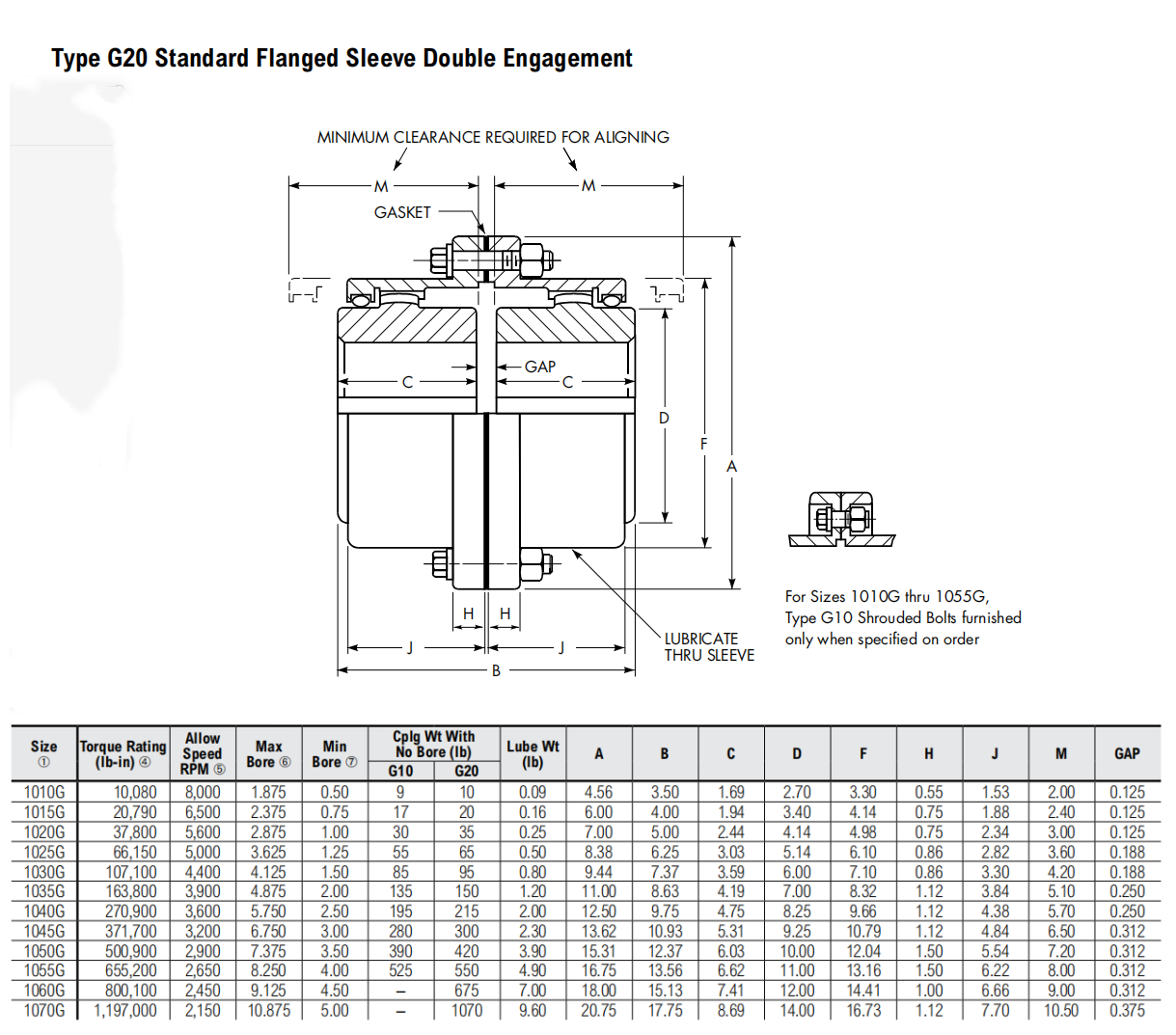

Quick Details

-

Standard or Nonstandard:

-

Standard

-

Material:

-

Steel

-

Brand Name:

-

JUDE

-

Place of Origin:

-

Hebei, China

-

Product name:

-

Flexible Couplings Coupler

-

Body Material:

-

45# Steel

-

Color:

-

Custom Requirement

-

MOQ:

-

1 Set

-

Size:

-

Custom Dimension Acceptable

-

Application:

-

Industrial Equipment

-

Feature:

-

Long Operating Life

-

Features 1:

-

High Torque High Rigidity

-

Packing:

-

Wooden Box

-

custom:

-

yes

Quick Details

-

Warranty:

-

1 year

-

Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

-

Structure:

-

Gear

-

Standard or Nonstandard:

-

Standard

-

Material:

-

Steel

-

Brand Name:

-

JUDE

-

Place of Origin:

-

Hebei, China

-

Product name:

-

Flexible Couplings Coupler

-

Body Material:

-

45# Steel

-

Color:

-

Custom Requirement

-

MOQ:

-

1 Set

-

Size:

-

Custom Dimension Acceptable

-

Application:

-

Industrial Equipment

-

Feature:

-

Long Operating Life

-

Features 1:

-

High Torque High Rigidity

-

Packing:

-

Wooden Box

-

custom:

-

yes

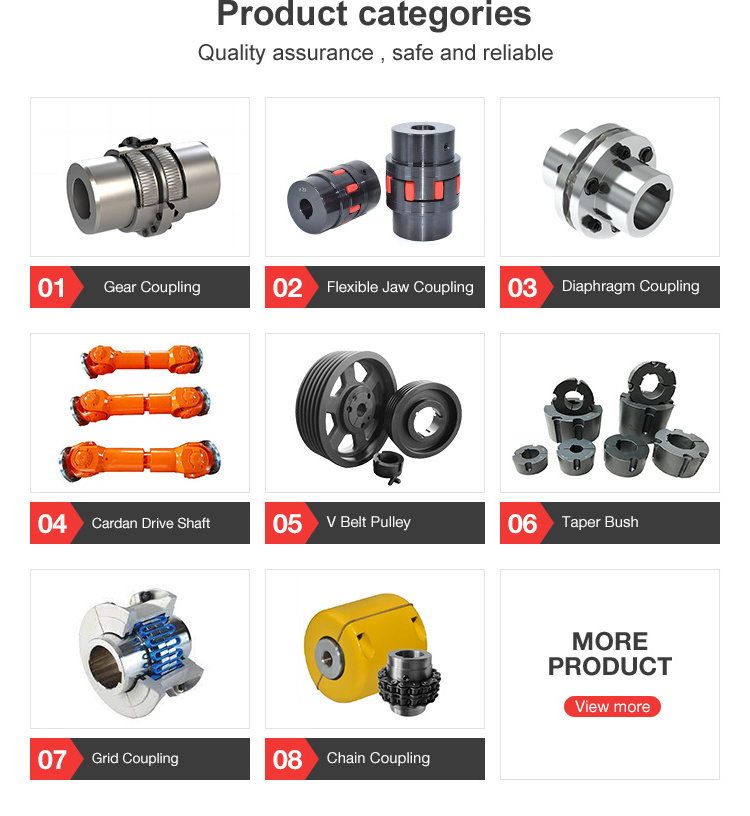

Product Description

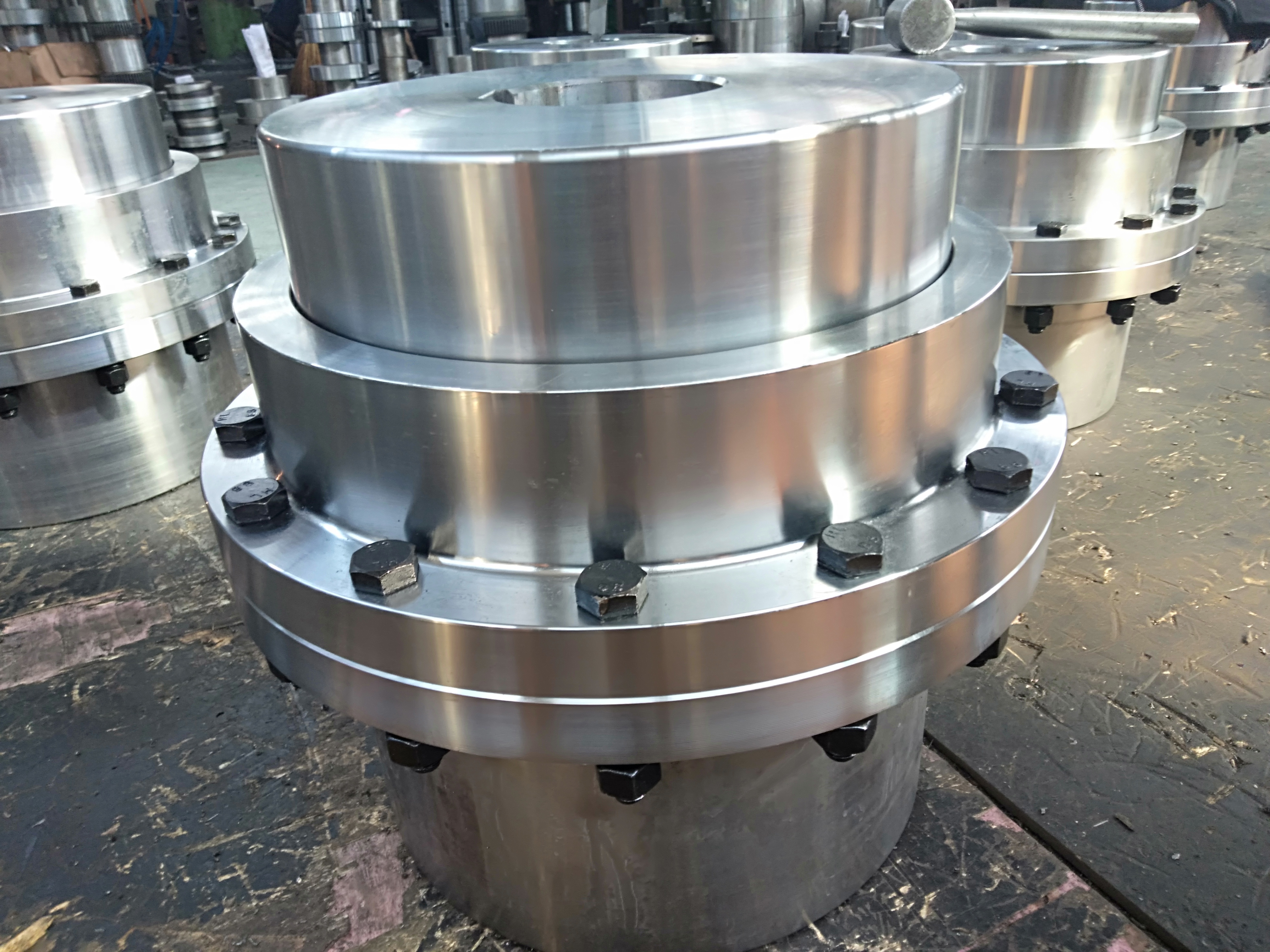

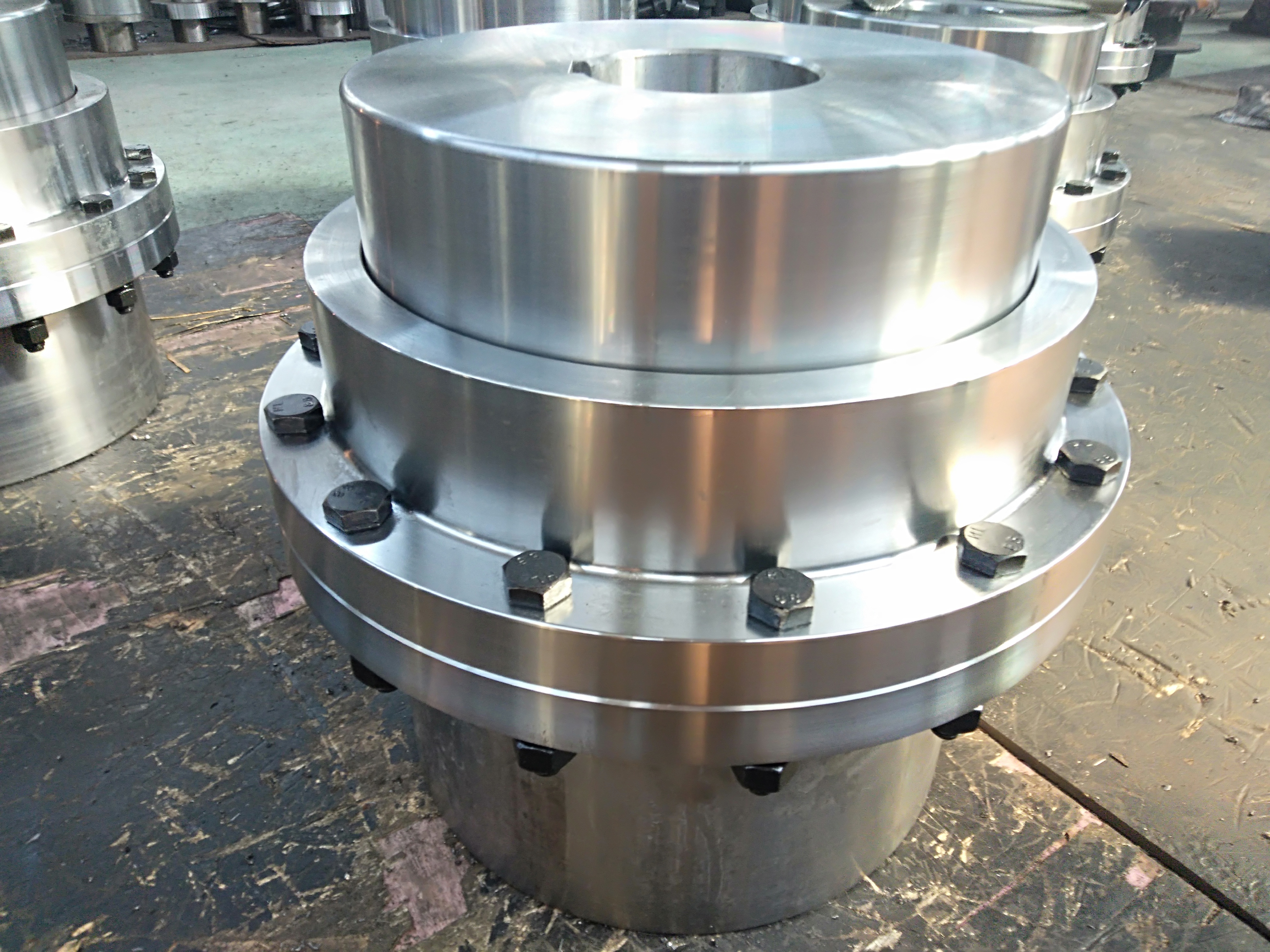

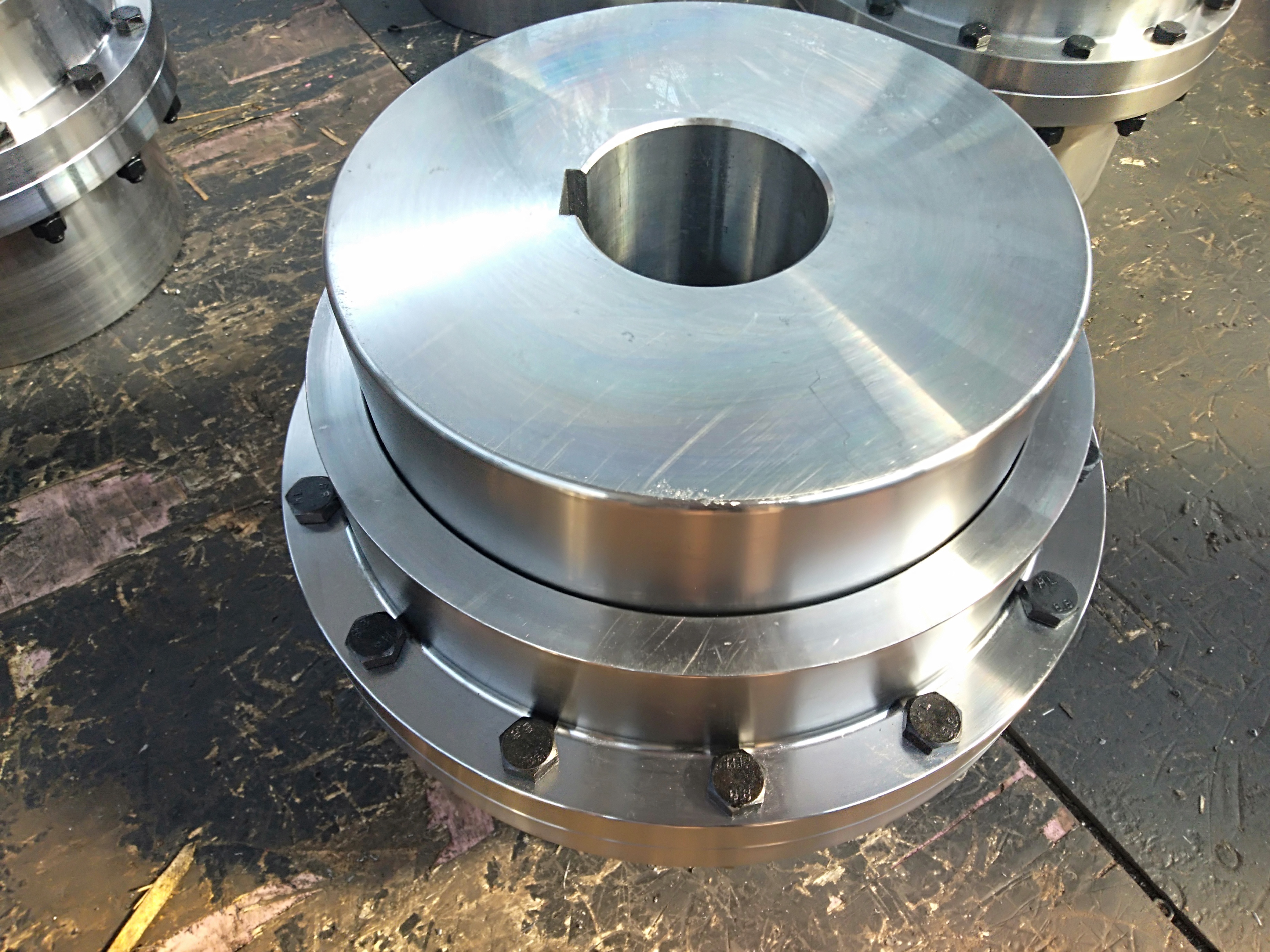

WGP Drum Gear Coupling With Brake Disc has a brake disc, brake disc can rotate speed by controlling the speed to adjust the machine. As shown in figure WGP with brake drum set type gear coupling is divided into I type and II type two forms, the only difference is that the brake disc is different.

The characteristics of CL type tooth coupling

:

1. Strong load-bearing capacity. Under the same outer diameter of the inner gear sleeve and the maximum outer diameter of the coupling, the bearing capacity of the drum gear coupling is increased by an average of 15-20% compared to the straight gear coupling;

2. The angular displacement compensation is large. When the radial displacement is equal to zero, the allowable angular

displacement of the straight tooth coupling is 1o, while the allowable angular displacement of the drum tooth coupling is 1o30 ', an increase of 50%. Under the same modulus, number of teeth, and tooth width, the allowable angular displacement of drum shaped teeth is greater than that of straight teeth;

3. The drum shaped tooth surface improves the contact conditions between the inner and outer teeth, avoiding the drawbacks of extrusion and stress concentration at the edge of straight teeth under angular displacement conditions. At the same time, it improves the friction and wear conditions of the tooth surface, reduces noise, and has a long maintenance cycle;

4. The outer gear sleeve has a horn shaped tooth end, making it very convenient to assemble and disassemble the inner and outer teeth;

5. Transmission efficiency up to 99.7%;

Based on the above characteristics, drum shaped teeth have been widely used domestically and internationally to replace straight tooth couplings.

1. Strong load-bearing capacity. Under the same outer diameter of the inner gear sleeve and the maximum outer diameter of the coupling, the bearing capacity of the drum gear coupling is increased by an average of 15-20% compared to the straight gear coupling;

2. The angular displacement compensation is large. When the radial displacement is equal to zero, the allowable angular

displacement of the straight tooth coupling is 1o, while the allowable angular displacement of the drum tooth coupling is 1o30 ', an increase of 50%. Under the same modulus, number of teeth, and tooth width, the allowable angular displacement of drum shaped teeth is greater than that of straight teeth;

3. The drum shaped tooth surface improves the contact conditions between the inner and outer teeth, avoiding the drawbacks of extrusion and stress concentration at the edge of straight teeth under angular displacement conditions. At the same time, it improves the friction and wear conditions of the tooth surface, reduces noise, and has a long maintenance cycle;

4. The outer gear sleeve has a horn shaped tooth end, making it very convenient to assemble and disassemble the inner and outer teeth;

5. Transmission efficiency up to 99.7%;

Based on the above characteristics, drum shaped teeth have been widely used domestically and internationally to replace straight tooth couplings.

production process

Hot Searches