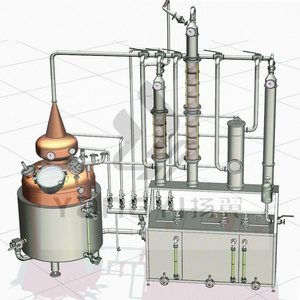

The 5l distillery equipment consists of a pot made of copper, glass, and copper columns combined, a partial condenser, and acondenser, which are heated using steam or electricity. The distillery equipment is a single unit designed to meet and exceed the needs of start-up distilleries and can be used as advanced test distillery equipment for mature distilleries of whisky, gin, fruit

brandy, rum, wine spirits. Micet Craft provides a complete distillation process system including mash tun, fermentation tank,spirit storage tanks, wine tanks, etc.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

6KW

-

Weight:

-

10 KG

-

Dimension(L*W*H):

-

2100*850*2000MM

-

Processing Types:

-

alcohol

-

Product name:

-

Alcohol Distilling Equipment

-

Usage:

-

Alcohol Distilling

-

Heating method:

-

Electrical Heating Steam Hearting

-

Function:

-

Brewing Production

-

Feature:

-

High Outpuit

-

Application field:

-

Food & Beverage Factory, Restaurant, Other

-

Material:

-

Stainless Steel 304/SUS316/Copper

-

Packing:

-

Plywood Box

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Micet

-

Model Number:

-

5L

-

Voltage:

-

220V/380V

-

Power:

-

6KW

-

Weight:

-

10 KG

-

Dimension(L*W*H):

-

2100*850*2000MM

-

Processing Types:

-

alcohol

-

Product name:

-

Alcohol Distilling Equipment

-

Usage:

-

Alcohol Distilling

-

Heating method:

-

Electrical Heating Steam Hearting

-

Function:

-

Brewing Production

-

Feature:

-

High Outpuit

-

Application field:

-

Food & Beverage Factory, Restaurant, Other

-

Material:

-

Stainless Steel 304/SUS316/Copper

-

Packing:

-

Plywood Box

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

After-sales Service Provided:

-

Field installation, commissioning and training

5L Copper Column Alcohol Distiller Distillation Equipment For Sale

Product Advantages

Copper head process

Quick loading and copper welding method is one-time turn over welding, to ensure that the parts in contact with the wine are made of copper material, beautiful bright side; Sealing is mainly by the sealing ring pressure, no welding position, so as to improve the service life of the equipment.

The manhole is made of red copper and welded with stainless steel flange to ensure that all parts in contact with wine are made of copper, with strong sealing performance and long service life.

Distillation tower process

The contact parts with wine gas are made of red copper, and the design process of turning welding is adopted.

Quality Assurance

All equipment has a one-year warranty from the date of delivery of the equipment. We provide on-site installation for commercial equipment through a professional team.

Material is introduced

Glass

This glass is widely used for the safe production of spirits on stills. The seller can easily know when the distillation process ends and can also resist the high temperature.

Copper

Copper can help neutralize sulfur compounds and improve the taste and odor of the final product, plus copper conducts heat better than stainless steel, which saves time on initial heating but also means increased heat loss.

Stainless steel

Stainless steel is very resistant to high temperatures, dents, and all stainless steel parts used on distillation equipment have a hygienic polish that lasts for a long time and doesn't breed bacteria.

Product Parameters

|

Design

|

5L Multi-functional distiller

|

||

|

Heating

|

Electric/Steam/Gas

|

||

|

Specifications

|

Configure electric ceramic stove

|

||

|

|

T2 copper material

|

||

|

|

Mirror polishing

|

||

|

|

Appearance of fish scales

|

||

|

|

With electric control panel( only electric heating needed)

|

||

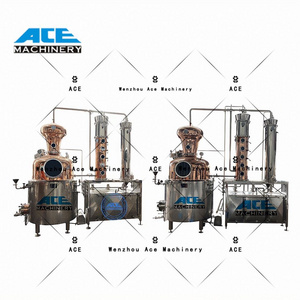

Products Show

Product Details

Project Cases

Our Company

Hot Searches