- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

+-10ml

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Guangdong, China

-

Dimension(L*W*H):

-

2400*1500*2300mm

-

Weight:

-

2500KG

-

Filling Capacity:

-

2000-20000bph

-

Suitable bottle size:

-

330-2000ml

-

Suitable bottle diameter:

-

50-90mm

-

Suitable bottle height:

-

150-340mm

-

Bottle Cap:

-

Plastic Screw Cap

-

Control System:

-

PLC / Touch Screen

-

Structure:

-

Rotary

-

Material:

-

Stainless Steel 304

-

Function:

-

Bottle washing filling capping

-

Certification:

-

CE ISO

Quick Details

-

Machinery Capacity:

-

4000BPH

-

Packaging Material:

-

Glass, Metal, Paper, Plastic, Wood

-

Filling Material:

-

Beer, Water, Juice

-

Filling Accuracy:

-

+-10ml

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Guangdong, China

-

Dimension(L*W*H):

-

2400*1500*2300mm

-

Weight:

-

2500KG

-

Filling Capacity:

-

2000-20000bph

-

Suitable bottle size:

-

330-2000ml

-

Suitable bottle diameter:

-

50-90mm

-

Suitable bottle height:

-

150-340mm

-

Bottle Cap:

-

Plastic Screw Cap

-

Control System:

-

PLC / Touch Screen

-

Structure:

-

Rotary

-

Material:

-

Stainless Steel 304

-

Function:

-

Bottle washing filling capping

-

Certification:

-

CE ISO

| Related products | ||

|

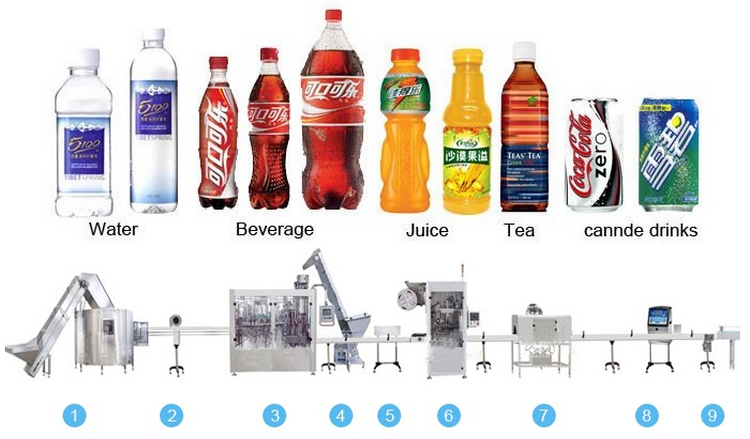

1. Bottle unscrambler 2. Air conveyor 3. Washing ,filling,capping 3 in 1 machine

4. Feeding machine 5. Light check 6.Labeling machine

|

||

|

|

|

| Pure water treatment machines | Mineral water treatment machines | Sachet packaging machines |

| 3-5 Gallon filling machine | ||

Give me the basic information about you want:

1.what kind products will you produce: water, juice, with gas or others.

2.what is your capacity you want: that how many bottles per hour you want.

3.what kind of the bottle: pet bottle or glass bottle; bottle volume;bottle sharp. bestly give me the bottle picture.

4.the single machine or the whole line.

So that I can make suitable proposal for you.....

| CLICK TO CONTACT US! > |

This model special for liquid bottle filling, combined with rinsing, filling and capping. It is innovated and designed in the requirement of carbonated beverage technics, on the bases of introducing, digesting and absorbing advanced technology abroad. It is reasonable in structure, safe to operate and easy to maintain, which is an ideal choice for beverage producers.

1. This series production line collected washing, filling, capping, labeling and packing m achines together.

2. We adopted advanced normal pressure gravity for filling, the filling effect are fast, steady, quasi and equipped with the material recirculating system, realize backflow independently, not contact with material and avoiding second pollution and oxidation.

3. The whole production line adopts human-machine interfaces, touch-screen, PLC computer controller and other advanced technologies.

4. With automatic inspect system of filling temperature automatic, caps supplying material high-temperature alarm, low-temperature shutdown and automatic retum, no bottle, no vorer, wait when lack of bottles, lacking caps shutdown and so on, realize no bottle, no filling.

5. Output range is 2000-20000bottles/hour. (can fill 0.2L and 2L with one machine, but have to change some fittings)

6. We adopt magnetic torque capping head. labeling machine is desiqned by our self with stainless steel frame. Shrink packing machine adopted original imported parts from Germany, Japan.

7. The machine is used in production of

bottled non-carbonated drink, fruit juice, mineral water and pure water.

Technology parameters

| Model |

Washing

heads |

Filling heads |

Capping heads |

Capacity(b/h) 500ml |

Motor power (KW) |

Overall dimension (mm) |

| MIC-8-8-3 | 8 | 8 | 3 | 2000-3000 | 1.2KW | 2000x1250x2200 |

| MIC-16-12-6 | 16 | 12 | 6 | 2000-4000 | 1.5KW | 2100x1400x2500 |

| MIC-16-16-6 | 16 | 16 | 6 | 3000-5000 | 1.8KW | 2460x1720x2650 |

| MIC-18-18-6 | 18 | 18 | 6 | 4000-6000 | 2.4KW | 3100x2100x2650 |

| MIC-24-24-8 | 24 | 24 | 8 | 6000-9000 | 3.2KW | 3500x2500x2650 |

| MIC-32-32-10 | 32 | 32 | 10 | 10000-12000 | 4.5KW | 4030x2220x2530 |

| MIC-40-40-10 | 40 | 40 | 10 | 16000-20000 | 7.5KW | 4600x1800x2650 |

The sample service

1.We can send you the video of the running machine.

2.You are welcome to come to visit our company to see the machine running in our factory,we can pick you up from the station near our city.

3.If we get the permission of our customer,we can tell you our old customer contact imformation.

Customized service

1.We can design the machines according your requirements (materil ,power,filling type,bottles, and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

2.We offer free technical support and consultation,such as draw the factory layout for you, alalyze the source water report and so on.

After-sales service

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly.

2.When you finish the Preparation conditions ,our fast and professional after service engineer teamwill go to your factory to install the machine,give you the operating manual ,and train your employee until they can operate the machine well.

3.We provide one year warranty with spare parts free.

4.We ask the feedback from our customer and offer some help when the machine have been used for some time.