- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

cnc machining

-

Brand Name:

-

oem/odm

-

MOQ:

-

1 Piece

-

Material:

-

Stainless Steel,aluminum,brass,copper,PC,POM,acrylic etc

-

Process:

-

CNC Macining/3D Printing/Rapid Prototyping

-

Color:

-

Customized Color

-

Surface treatment:

-

Sandblasting,anodizing,laser engraving,high polishing etc

-

Lead time:

-

3-7 days

-

Tolerance:

-

0.1-0.2mm

-

Service:

-

Customized OEM CNC Machining

-

Application:

-

Car, Household Appliances,Furniture,Commodity,Electronic etc

-

Keyword:

-

cnc machining parts

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, ABS, POM, PP, PC, PE, PA(Nylon),rubber,silicone,polyurethane,etc

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

cnc machining

-

Brand Name:

-

oem/odm

-

MOQ:

-

1 Piece

-

Material:

-

Stainless Steel,aluminum,brass,copper,PC,POM,acrylic etc

-

Process:

-

CNC Macining/3D Printing/Rapid Prototyping

-

Color:

-

Customized Color

-

Surface treatment:

-

Sandblasting,anodizing,laser engraving,high polishing etc

-

Lead time:

-

3-7 days

-

Tolerance:

-

0.1-0.2mm

-

Service:

-

Customized OEM CNC Machining

-

Application:

-

Car, Household Appliances,Furniture,Commodity,Electronic etc

-

Keyword:

-

cnc machining parts

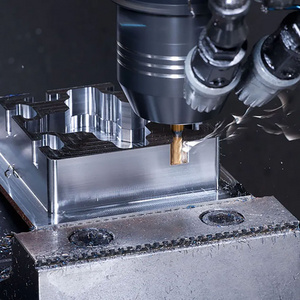

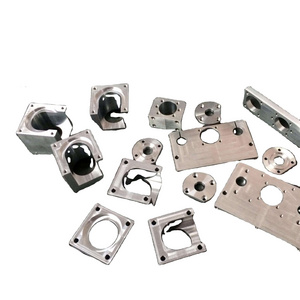

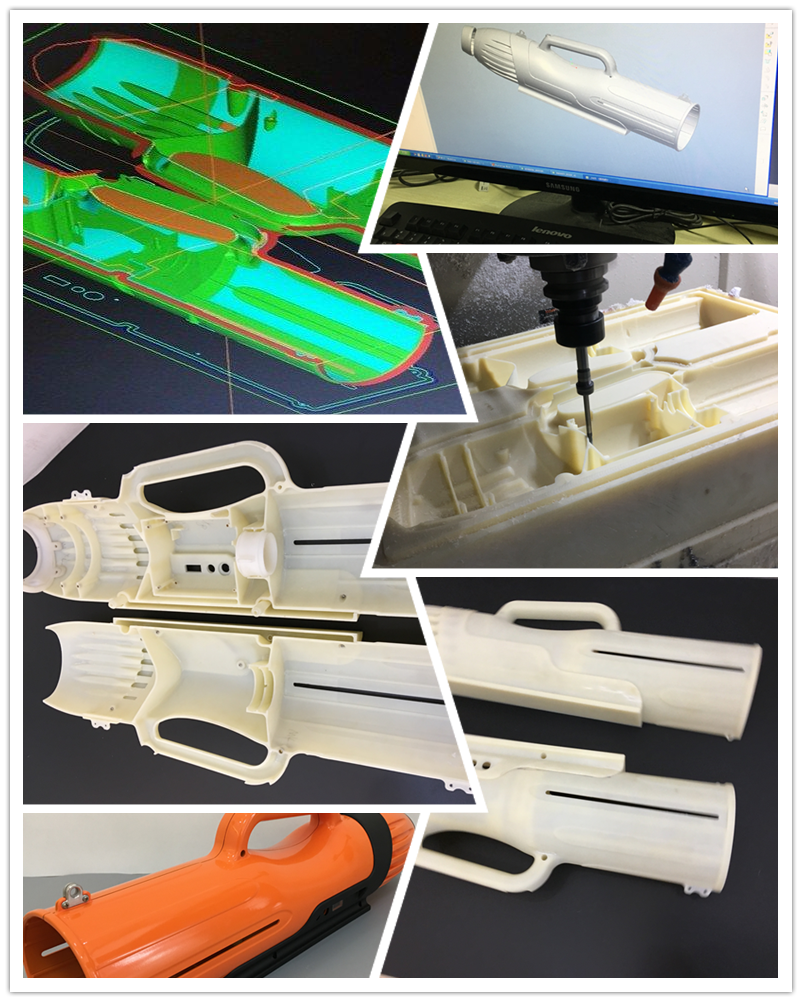

CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls and machine tools to remove material from a workpiece to create a custom-designed part or product. CNC machining is commonly used for both plastic and metal materials. Here's an overview of CNC plastic machining and CNC metal machining services:

CNC Plastic Machining:

Materials:

1.Acrylic (PMMA): Transparent and lightweight, often used for signage and display components.

2.Polyethylene (PE): Durable and chemical-resistant, suitable for various applications.

3.Polypropylene (PP): Lightweight, resistant to chemicals, often used in automotive and medical industries.

4.Polycarbonate (PC): Impact-resistant, transparent, and commonly used for safety glasses, lenses, etc.

Applications:

1.Prototyping: CNC machining is excellent for creating prototypes of plastic parts before mass production.

2.Medical Devices: Plastic machining is often used for components in medical devices due to its biocompatibility.

3.Aerospace: Lightweight plastic parts are used in aircraft interiors, drones, and other aerospace applications.

4.Consumer Electronics: Custom plastic parts for electronic devices and housings.

Advantages:

1.Precision: CNC machining ensures high precision and accuracy in plastic part production.

2.Versatility: Suitable for complex shapes and intricate designs.

3.Fast Prototyping: Quick turnaround for prototyping and small production runs.

Considerations:

1.Material Selection: Choose the right plastic material based on the application requirements.

2.Tooling: Proper tooling and cutting parameters are crucial for achieving high-quality plastic parts.

CNC Metal Machining:

Materials:

1.Aluminum: Lightweight, corrosion-resistant, and widely used in aerospace, automotive, and electronics.

2.Stainless Steel: Durable, corrosion-resistant, and commonly used in medical, food processing, and automotive industries.

3.Brass: Corrosion-resistant, with a decorative appearance, often used in musical instruments and fittings.

4.Titanium: High strength, lightweight, and used in aerospace, medical implants, and sports equipment.

Applications:

1.Automotive Parts: Engine components, brackets, and other metal parts for automobiles.

2.Aerospace Components: Critical components for aircraft and spacecraft.

3.Medical Devices: Precision-machined metal parts for medical instruments and implants.

4.Electronics: Metal housings, heat sinks, and other components for electronic devices.

Advantages:

1.Strength and Durability: CNC metal machining produces robust and durable parts.

2.Tight Tolerances: High precision and tight tolerances are achievable with CNC metal machining.

3.Material Variety: Suitable for a wide range of metal materials.

Considerations:

1.Material Hardness: Consider the hardness of the metal and select appropriate tools.

2.Cooling and Lubrication: Proper cooling and lubrication are essential to prevent tool wear and ensure quality machining.

In both CNC plastic and metal machining, the key is to choose the right materials, tools, and machining parameters based on the specific requirements of the project. Working with a reputable CNC machining service provider can help ensure the quality and precision of the final products.

| Quotation | According to your drawing(size, material, thickness, processing content and required technology, etc.) |

| Available Service | 1.Design |

| 2. CNC Rapid Prototyping | |

| 3. SLS/SLA/3D Printing Prototype Service | |

| 4. High Precision CNC Machining | |

| 5. Silicone Mold (Vacuum Casting) & Rapid Tooling | |

| Material | Aluminum(6061,6063,mic6), stainless steel,brass,ABS,PC,POM, PP, PE, PA(Nylon),acrylic,wood,carbon fiber,copper, etc |

| Surface treatment | Polished, High polishing, Anodizing, Painting, Electroplating, Laser Engraving, Sand blasting, Brushed etc |

| Drawing Format | STEP File/PROE, Auto CAD, Solid Works |

| Anodized colors | Do as pantone,Accept customization |