- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

1300 mm

-

Travel (Y Axis)(mm):

-

2500 mm

-

Repeatability (X/Y/Z) (mm):

-

0.02 mm

-

Spindle Motor Power(kW):

-

3.2KW

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GoodCut CNC

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

1300*2500*200mm

-

Power (kW):

-

3.2

-

Weight (KG):

-

1300

-

Product name:

-

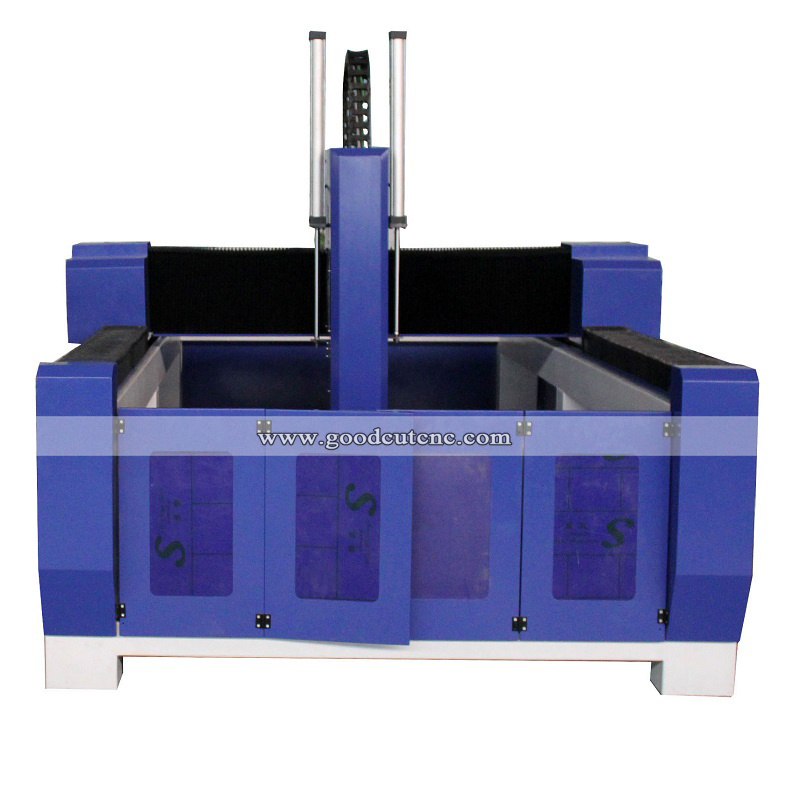

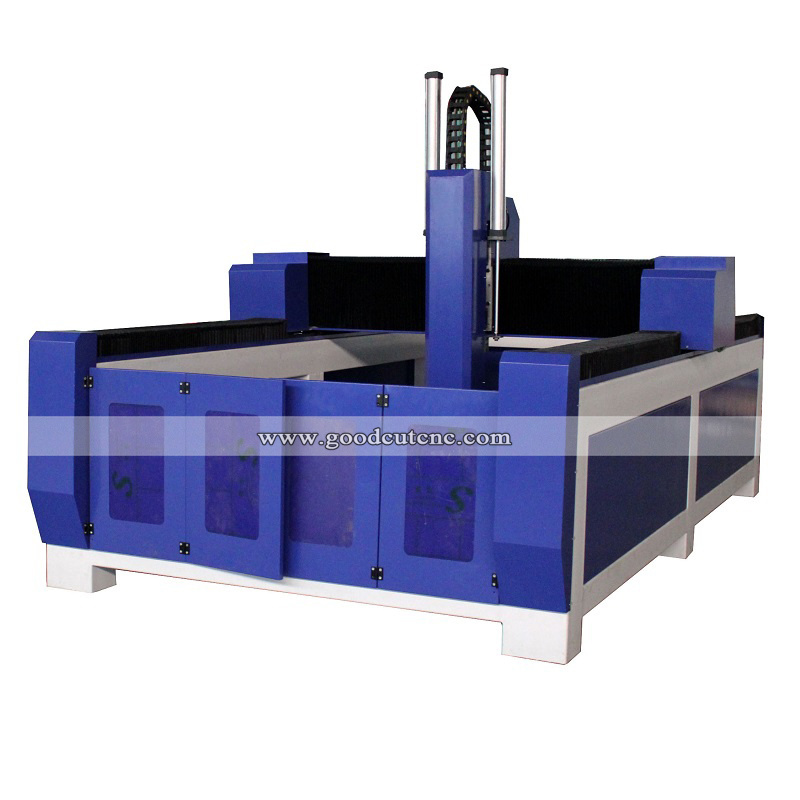

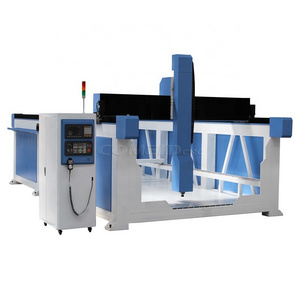

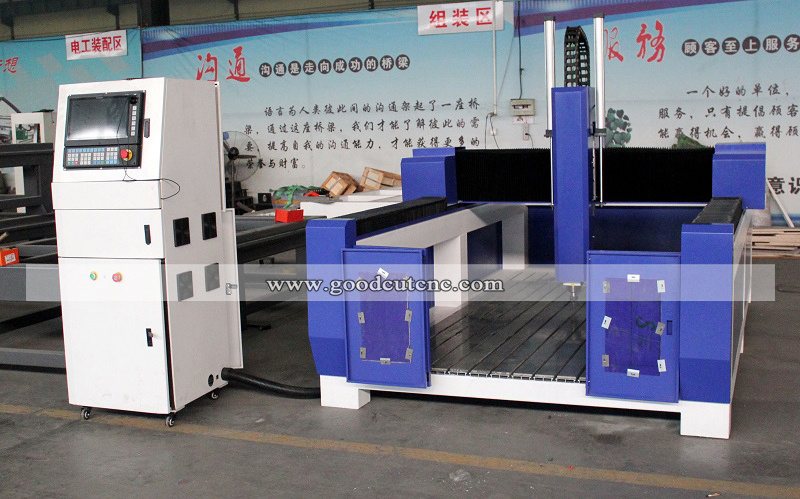

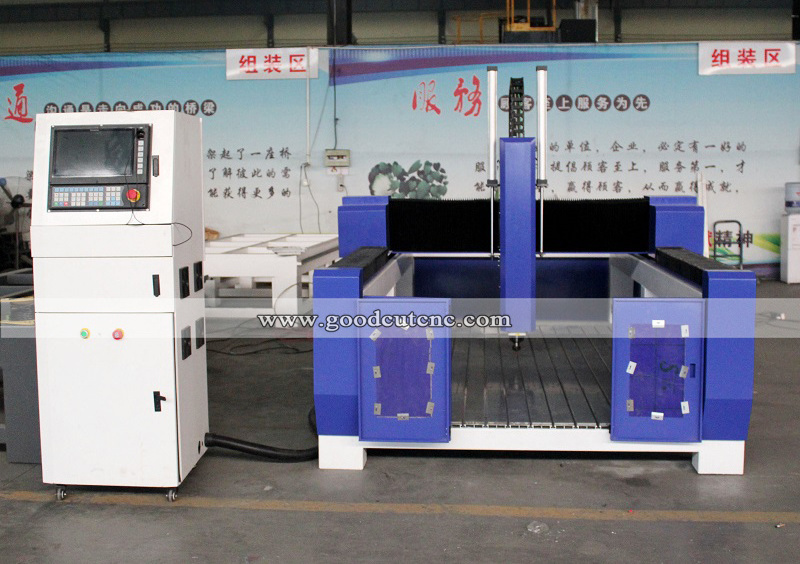

1325 Foam EPS Cnc Foam Cutting Machine

-

Working area:

-

1300x2500x300mm

-

Application:

-

3d foam EPS engraving or cutting

-

Control system:

-

Mach3/DSP/ SYNTEC/Weihong NK105

-

Transmission:

-

Helical Rack Pinion, Taiwan TBI ball screw

-

Spindle power:

-

HQD 3.2kw 4.5kw 5.5kw 6kw air or water cooling spindle

-

Table:

-

Aluminium T.Slot Table

-

Drive motor:

-

Leadshine/Delta/Yaskawa servo motor

-

Inverter:

-

Fuling, BEST

-

Optional:

-

Rotary device, 180 degree rotated spindle

Quick Details

-

Working Table Size(mm):

-

1300×2500

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

1 - 24000 rpm

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

1300 mm

-

Travel (Y Axis)(mm):

-

2500 mm

-

Repeatability (X/Y/Z) (mm):

-

0.02 mm

-

Spindle Motor Power(kW):

-

3.2KW

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GoodCut CNC

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

1300*2500*200mm

-

Power (kW):

-

3.2

-

Weight (KG):

-

1300

-

Product name:

-

1325 Foam EPS Cnc Foam Cutting Machine

-

Working area:

-

1300x2500x300mm

-

Application:

-

3d foam EPS engraving or cutting

-

Control system:

-

Mach3/DSP/ SYNTEC/Weihong NK105

-

Transmission:

-

Helical Rack Pinion, Taiwan TBI ball screw

-

Spindle power:

-

HQD 3.2kw 4.5kw 5.5kw 6kw air or water cooling spindle

-

Table:

-

Aluminium T.Slot Table

-

Drive motor:

-

Leadshine/Delta/Yaskawa servo motor

-

Inverter:

-

Fuling, BEST

-

Optional:

-

Rotary device, 180 degree rotated spindle

4 Axis 1325 Foam EPS Cnc Foam Cutting Machine for Styrofoam Wood Aluminium Mold

|

No. |

Item |

|

Parameters |

|

1 |

Working area |

X |

1300mm (Option ) |

|

Y |

2500mm (Option) |

||

|

Z |

400mm |

||

|

2 |

Table |

Size |

1300x2500mm |

|

Material |

foam ,wood .... |

||

|

3 |

Accuracy |

Working Accuracy |

±0.05mm |

|

Repositioning Accuracy |

±0.03mm |

||

|

Straightness for X,Y,Z |

±0.05/300mm |

||

|

Verticality for X to Y |

0.05/ m |

||

|

Verticality for Z to X,Y |

0.03/m |

||

|

Straightness for table surface |

0.05/500mm |

||

|

Verticality for spindle |

0.1/300mm |

||

|

4 |

Structure |

Table Structure |

Whole welding Steel tube |

|

Transmission way of X,Y,Z |

XY with HIWIN Linear rail, Z with Ball screw |

||

|

5 |

Speed |

Feed |

1-30000mm/min |

|

Rapid feed rates |

X=12000mm/min |

||

|

Y=12000mm/min |

|||

|

Z=10000mm/min |

|||

|

6 |

Spindle |

Spindle Power |

6.0KW air Coolant Spindle made in Italy |

|

Spindle Speed |

100-12000 RPM /min |

||

|

Spindle taper |

ER32 |

||

|

Spindle Nose to Table Top |

150-950mm |

||

|

7 |

Driver |

|

Japanese Yaskawa Servo motor |

|

8 |

Working Voltage |

|

AC380V/50Hz |

|

9 |

Commend Code |

|

G Code ,F/S Code Compatible |

|

10 |

Operating System |

|

DSP A18/Syntec /nc studio 4axis |

|

11 |

Net Weight |

|

2100 KGS |

1.Large-scale three-dimensional surface modeling.

2.Z axis height can be increased the 1.5 meters, processing large sized, suitable for large three-dimensional surface machining.

3.Intelligent processing crossborder protection, to prevent the mechanical impact due to excessive design documents processing.

4.Diversity control can control the processing speed, idling speed, the cutting speed, greatly improving the quality of processed product and processing efficiency.

5. Many kinds of sizes are optional according to your request.

Industrial Design: main model processing and design of automobile, yacht, high-speed rail EMU and other products

Composite materials: glass fiber reinforced plastic mold, cutting and trimming of glass fiber reinforced plastic products, cutting and trimming of ABS Blister products, processing of wind power cover, precision processing of yacht hull and interior parts of high-speed rail EMU, etc. Mold industry: glass fiber reinforced plastic wood mold, casting wood mold, foam wood resin products and other non-metallic mold five axis processing.

Bathroom industry: gypsum mold and various gypsum products processing. Landscape sculpture industry: Carve and cut on any kind of foam with 2D and 3D dimension processing Furniture industry: high end solid wood furniture, mortise and mortise parts, stair turning head, chair back and other five axis processing.

Applicable materials:

polystyrene foam (EPS), epoxy, wood, timber, fiberglass, MDF, plastic, wax, sand, resin and other materials.

Jinan GoodCut CNC Machinery Co., Ltd.

The meaning of “GoodCut” brand: Good Quality, Good Price, Good Service

Good Quality

1. 15 engineers with more than 10 years rich working experience, manufacture high precision machines;

2. Three-day 72-hour testing machine inspection, after confirming that the machine has no quality problems, then it will be shipped;

3. 4 QC staffs do strict evaluations on in-coming inspections, in-process inspections and final inspections.

Good Price

1. GoodCut manufactures about 50 sets of machines per month, with a large sales volume. We have long-term cooperation with parts suppliers, can get advantageous prices of parts, so that the price of machine is very competitive;

2. GoodCut aims to develop long-term cooperation with new and regular customers, and to give customers the best prices with the most sincere attitude.

Good Service

1. English manual and video for machine using and maintaining, explaining the operation steps in detail;

2. Professional after-sales service staffs, providing 24-hour online service;

3. Provide free technical training and factory field operation teaching to eliminate customer worries.