- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

450

-

Voltage:

-

380V,50HZ

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FILLING AUTO BRAND

-

Dimension(L*W*H):

-

1070*690*2070mm

-

Product name:

-

Automatic Backing Sealing Auger Powder Packing Sealing Machine

-

Filling range:

-

5g-5000g

-

Max width film-making:

-

Max.420mm

-

Length of bag-making:

-

80-350mm

-

Width of bag-making:

-

80-200mm

-

Weight:

-

450kg

-

Max. diameter of coil:

-

Max.360mm

-

Speed of packing:

-

10-30 bags/min

-

After-sales Service Provided:

-

Video Technical SupportOnline Support

Quick Details

-

Function:

-

FILLING, Sealing, counting

-

Packaging Type:

-

Bags

-

Packaging Material:

-

Plastic, Paper

-

Weight (KG):

-

450

-

Voltage:

-

380V,50HZ

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FILLING AUTO BRAND

-

Dimension(L*W*H):

-

1070*690*2070mm

-

Product name:

-

Automatic Backing Sealing Auger Powder Packing Sealing Machine

-

Filling range:

-

5g-5000g

-

Max width film-making:

-

Max.420mm

-

Length of bag-making:

-

80-350mm

-

Width of bag-making:

-

80-200mm

-

Weight:

-

450kg

-

Max. diameter of coil:

-

Max.360mm

-

Speed of packing:

-

10-30 bags/min

-

After-sales Service Provided:

-

Video Technical SupportOnline Support

Product Details

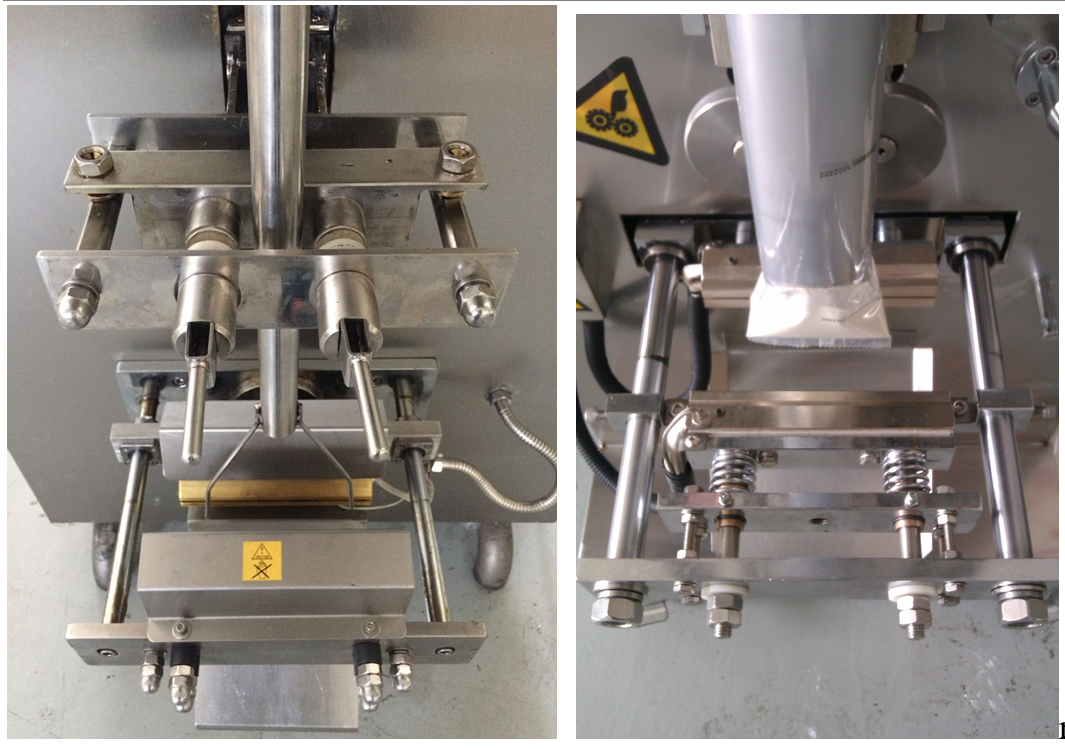

Major performance and structural characteristics:

1. automatic to complete all of the production process: feeding, weighing, making

bag, filling, sealing, printing date and outputting products.

2. high accuracy in measurement and efficiency.

3. save manpower, low loss, easy to operate and to maintain

Features:

1. English and Chinese screen display ,operation is simple .

2. PLC computer system , function is more stable , adjustment any parameters not need stop machine.

3. It can stock ten dispose , simple to change variety.

4. Sever motor drawing film , position accurately.

5. Temperature independent control system ,precision get to±1℃.

6. Horizontal , vertical temperature control ,suitable for various of mix film , PE film

packing material.

7. Packing type diversification , pillow sealing, standing type ,punching etc.

8. Bag–making , sealing, packing, print date in one operation.

9. Work circumstance quiet, low noise.

Detailed Introduction :

Major performance and structural characteristics:

1. The machine is solid and stable in structure, simple in operation and easy in

maintenance.

2. This machine adopts the programmable control system and large touch-sensitive

screen, intuitively and easily to understand.

3. It adopts servo transport membrane system, accurate in positioning, beautiful in

packaging.

4. The whole process is automatic in measuring, filling, making bags, date printing

and output products.

5.According to customer’s needs, there are extra functions, such as a single package

and multi-cut feature, can be configured with the punching device.

Suitable for supporting:

Electronic weighing system, semi-automatic feeding device, spiral powder

measurement and cup-type measurement.

Scope:

it suitable for powder and small granule materials.

Parameters:

Type: BLN520

Air Consumption: 2.5 m3/min 6kg/cm2

Max width film-making: Max. 420mm

Length of bag-making: 80-350mm

Width of bag-making: 80-250mm

Max. diameter of coil: Max.360mm

Speed of packing: 15 bags/min

Thickness of film:0.04-0.08mm

Power: 380V、50Hz、2.4KVA

Weight: 450Kg

Product Name

: Feeding Machine

Model

: APT-01

Main Usage

:

This machine can be used with ZX series packing machine to reduce dust, lighten labour intensity and promote the efficiency

Specifications

Height of Transport: 1600mm

Weight of machine: 80KG

Capacity of Hopper: 100-300KG

Quantity of Transport: 500-3000KG/H

Material: Stainless Steel

QUOTATION

|

SPECIFICATIONS & CONFIGURATION :

|

|

|

|

|

||||

|

NAME

|

MODEL

|

UNIT PRICE

|

QUANTITY

|

SUB TOTAL(USD)

|

||||

|

Standard config. incudes:

|

|

|

|

|

||||

|

Auger feeding machine(Hopper 200L)

|

APT-01

|

|

1 set

|

|

||||

|

Powder filling machine(Hopper 50L)

|

ZX-F

|

|

1 set

|

|

||||

|

Automatic Packing machine

|

420

|

|

1 set

|

|

||||

|

Insertion angle device

|

|

|

1 set

|

|

||||

|

Finished production conveyor

|

|

|

1 set

|

|

||||

|

Spare parts(Bag forming and auger)

|

|

|

3 sets

|

|

||||

|

TOTAL FOB PRICE

|

|

|

|

|

||||

|

Note:

|

|

|

|

|

||||

|

The packing machine will be manufactured as customer requirements

|

|

|

|

|

||||

|

1.All the machine main part raw materials is 304 stainless steel.

|

|

|

|

|

||||

|

2.Motor is 380V 50HZ. Strong and reliable converter or stablizer to control the electric.

|

|

|

|

|

||||

|

3.The packing machine is suitable for packing powder and small granule materials.

|

|

|

|

|

||||

|

4. Auger feeding machine hopper 200L(Diameter 1140mm),Quick release structure, with cover for hopper.

Auger filling machine hopper 50L

Some powder touching part is 316L SS

Three sets spare parts for bag forming and auger filling nozzles for different size

|

|

|

|

|

||||

|

5..After selling service: ①.One-year Quality Assurance Lifelong Maintenance (the guarantee date starts from the day of machine

reaching your company). ②.We will send our engineer to your factory but you should responsible for the air ticket and accommodation. Our engineer will install the machine and teach your staff how to operate and maintence. the salary is 200USD per day. |

|

|

|

|

||||

Hot Searches