1. High recovery ratio;

2. High concentration ratio;

3. Easy installation;

4. Simple operation;

5. Deck constructed of fiber glass;

6. Ten different decks to choose;

7. Long working life;

8. Adjustable stroke length and speed.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

4500*1855*1546mm

-

Weight:

-

800 KG

-

Machine Type:

-

ore sorting machine

-

Feeding size:

-

0.15-2mm

-

processing capacity:

-

0.5-0.7t/h

-

deck material:

-

fiberglass steel

-

Usage:

-

gold,copper,iron,chrome,tin,etc.

-

recovery rate:

-

85-98%,depend on ore features

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Certification:

-

ISO9001:2015

Quick Details

-

Production Capacity:

-

high

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Hengzhong

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

4500*1855*1546mm

-

Weight:

-

800 KG

-

Machine Type:

-

ore sorting machine

-

Feeding size:

-

0.15-2mm

-

processing capacity:

-

0.5-0.7t/h

-

deck material:

-

fiberglass steel

-

Usage:

-

gold,copper,iron,chrome,tin,etc.

-

recovery rate:

-

85-98%,depend on ore features

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Certification:

-

ISO9001:2015

Product Overview

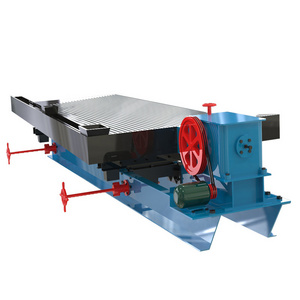

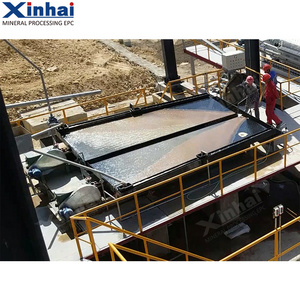

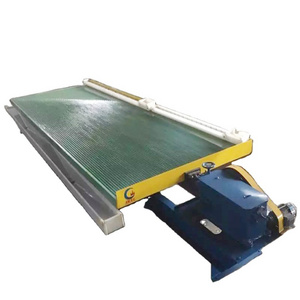

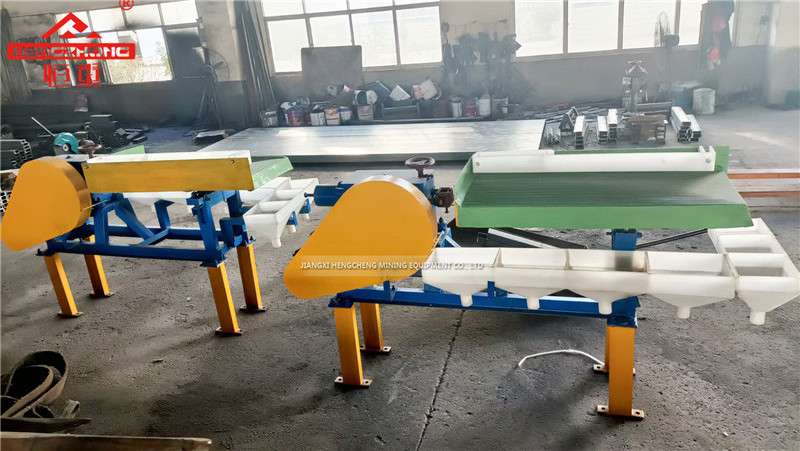

Gold Recovery Vibration Shaker Table

Shaking table which is also called table concentrator, it's effective in processing precious and base metal, rare metal and non-metallic minerals, widely used in separation for Gold, Silver, Tin, Columbium, Tantalum, Titanium, Barium, Tungsten, Iron, Chrome, Manganese, Zircon, Lead, Zinc, Mercury, Copper, Aluminum, etc. The range of effective separating particle size of shaking table is 2 to 0.022 mm.

Main Features

PRODUCT CONFIGURATION

Shaking Table

Key Component

Head Motion:

The head motion is of rugged construction and requires minimum maintenance. Its internal mechanism is splash lubricated from an integral oil sump.

Decks: The decks are built of 16 mm zircon-reinforced fiberglass with fabricated steel frames at the bottom and are easy to clean, requiring little maintenance. The specific gravity of fiberglass made into decks is one third of that of steel, while its strength reaches as high as 70% that of steel. This fiberglass desks also has the characteristic of water-resistance and corrosion-resistance and can hold the shape unchangeable at ±50°C.

Feed and Water Box: A wooden feed distributing box with hopper and a long water box are attached to the iron of the deck, giving a very even distribution of feed and water.

Stand Or Base: Three choices of ordinary type, groove steel support or big channel steel support is available.

Decks: The decks are built of 16 mm zircon-reinforced fiberglass with fabricated steel frames at the bottom and are easy to clean, requiring little maintenance. The specific gravity of fiberglass made into decks is one third of that of steel, while its strength reaches as high as 70% that of steel. This fiberglass desks also has the characteristic of water-resistance and corrosion-resistance and can hold the shape unchangeable at ±50°C.

Feed and Water Box: A wooden feed distributing box with hopper and a long water box are attached to the iron of the deck, giving a very even distribution of feed and water.

Stand Or Base: Three choices of ordinary type, groove steel support or big channel steel support is available.

Deck

Head

Stand

SIMILAR PRODUCTS

PRODUCT SPECIFICATIONS

Shaker Table have three distinct deck designs available.

The course ore deck is designed for recovering particles sized from 0.5 mm to 2 mm; the fine sand deck is designed for recovering fine particles in the range of 0.074 mm to 0.5 mm; the slime deck is designed for recovering super extremely fine particles in the range of 0.05 mm to 0.074 mm.

The course ore deck is designed for recovering particles sized from 0.5 mm to 2 mm; the fine sand deck is designed for recovering fine particles in the range of 0.074 mm to 0.5 mm; the slime deck is designed for recovering super extremely fine particles in the range of 0.05 mm to 0.074 mm.

|

Model

|

|

6-S

|

LY

|

LY

|

|

|

Deck Size

|

Length(mm)

|

4500

|

3000

|

2100

|

|

|

|

Transmission end width(mm)

|

1850

|

1620

|

1050

|

|

|

|

Concentrate end width(mm)

|

1560

|

1110

|

850

|

|

|

Beneficiation area(m2)

|

|

7.6

|

4.08

|

1.95

|

|

|

Feeding Size (mm)

|

Coarse sand Deck

|

2-0.5

|

2-0.5

|

2-0.5

|

|

|

|

Fine sand Deck

|

0.5-0.1

|

0.5-0.1

|

0.5-0.1

|

|

|

|

Slime Deck

|

0.1-0.037

|

0.1-0.037

|

0.1-0.037

|

|

|

Feeding amount (t/h)

|

Coarse sand Deck

|

1-2

|

0.6-1.5

|

0.4-0.8

|

|

|

|

Fine sand Deck

|

0.5-1

|

0.3-0.8

|

0.2-0.5

|

|

|

|

Slime Deck

|

0.3-0.5

|

0.2-0.4

|

0.1-0.2

|

|

|

Feeding Density (%)

|

|

10-30

|

10-30

|

10-30

|

|

|

Water Added (t/h)

|

|

0.5-3

|

0.3-1.5

|

0.2-1

|

|

|

Stroke (mm)

|

|

8-36

|

10-30

|

12-28

|

|

|

Frequency (F)

|

|

240-380

|

240-420

|

240-450

|

|

|

Transverse slope of Deck

|

|

0°-5°

|

0°-8°

|

0°-10°

|

|

|

Motor

|

Model

|

Y70L-4

|

Y100L-4

|

Y90L-4

|

|

|

|

Power (kw)

|

1.1

|

1.1

|

1.1

|

|

|

Weight (kg)

|

|

900

|

550

|

460

|

|

Successful Project

Project in Ghana

Project in Angola

Project in

Philippines

Packing & Shipment

1. All the goods will be delivered in 15-30 working days after receiving payment.

2. The machine will be packed in export container.

3. Motors and small parts will be packed in new strong wooden cases that suitable for long distance ocean transportation.

4. We promise that your goods will be shipped to destination timely and safely.

Hot Searches