- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

KEJIE

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

6m*1.6m*2.5m

-

Power (kW):

-

11

-

Weight:

-

2 KG

-

Automatic Grade:

-

Automatic

-

Power(W):

-

132KW

-

Color:

-

Yellow

-

After sale:

-

Provide accessories for life

-

Mould:

-

Supply

-

Marketing Type:

-

Hot Product 2021

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

38:1

-

Screw Speed (rpm):

-

75 rpm

-

Place of Origin:

-

China

-

Brand Name:

-

KEJIE

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

6m*1.6m*2.5m

-

Power (kW):

-

11

-

Weight:

-

2 KG

-

Automatic Grade:

-

Automatic

-

Power(W):

-

132KW

-

Color:

-

Yellow

-

After sale:

-

Provide accessories for life

-

Mould:

-

Supply

-

Marketing Type:

-

Hot Product 2021

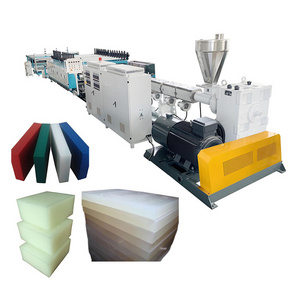

Product Overview

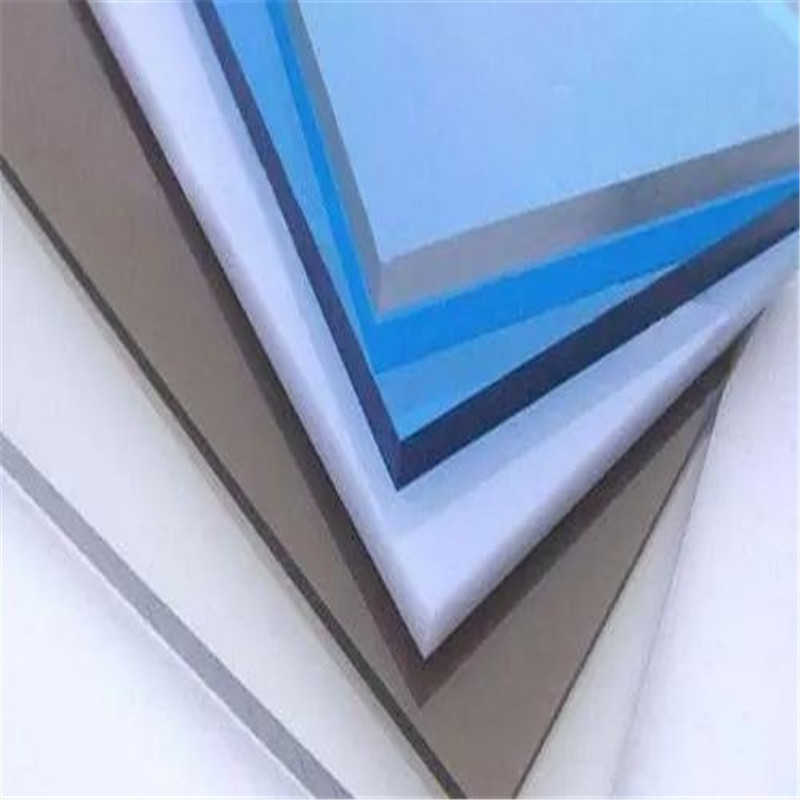

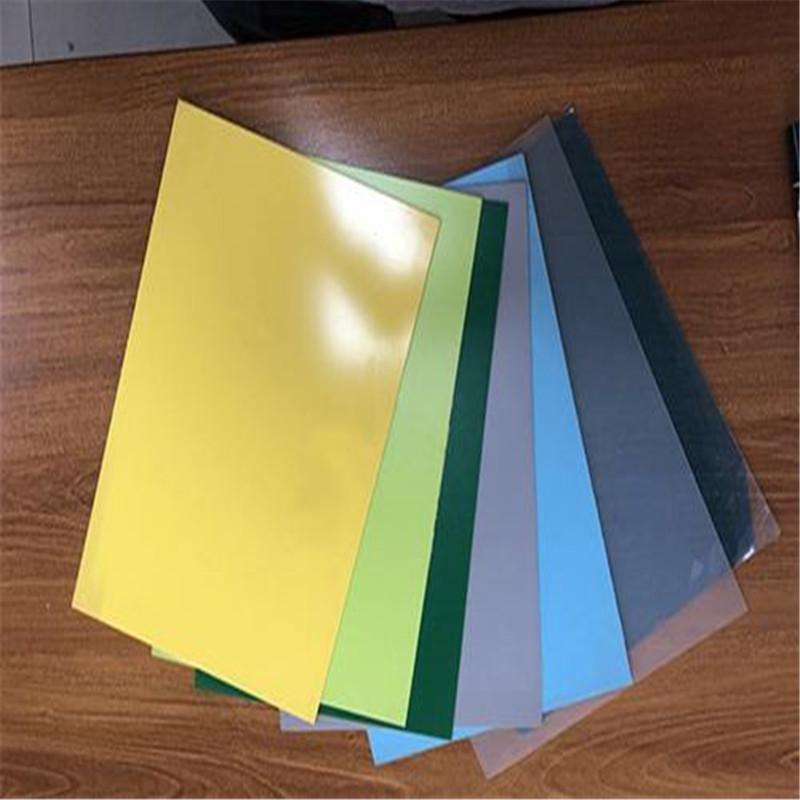

PC sheet extrusion line PETG /PET extruder PMMA board extruder making machine production line

PET/PETG/PMMA/PC sheet extrusion machine is one of the most advanced, mature and stable sheet extrusion lines. Compared with similar machinery, Superior performance is over 30% in integrated high efficiency. This line is also used for production of PS,PP, PE and other sheet products.

Uses: widely used instruments, instrument parts, lighting, decoration, construction, aircraft, auto parts, medical equipment,technology products, electrical insulation materials, specimens, signs, and a variety of light industry, culture and education,and daily necessities.

PET/PBT Single Layer or Multi-layer Sheet Extrusion Line

This line is specially used for producing PP/PE/PS/ABS/PVC single layer or multi-layer sheet or plate, suitable in the fields of packaging, stationery, chemicals, construction, household appliances and so on.

Main technical data:

1. Usual sheet width: 700, 900, 1020, 1200, 1300, 1400, 1500, 1700, 1800, 2100, 2200mm

2. Usual sheet thickness: 0.5-2mm, 1.5-10mm, 6-20mm, 3-30mm

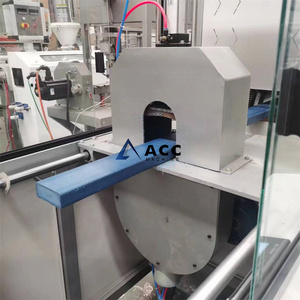

Extruder: Special screw structure, imported world-known thermocontrollers, electronics, hard gear face reducers to ensure high effective material extrusion capacity.

T -type die head: suitable compression ratio to ensure uniform flow stability.

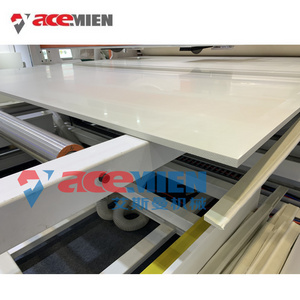

Three-roller calendar: According to the material properties, adopting vertical three-roller, oblique three-roller, horizontal three-roller calendar. Internal roller temperature control using a unique flow channel, so that the stability of uniform distribution roller. The independent oil temperature control for three roller to ensure more stable and exact control.

Cooling frame: According to product specifications, configurations with different specifications of the stainless steel

cooling rollerEdge-cutting devices: Trimming can be divided into manual and automatic, three-dimensional configuration tool adjustment device, width adjustable.

Cut off machine: Saw cutting or knife cutting, thin type and non-friable type sheet generally usually knife cut, adopted high-quality alloy cutting tools, sharp and durable.

Uses: widely used instruments, instrument parts, lighting, decoration, construction, aircraft, auto parts, medical equipment,technology products, electrical insulation materials, specimens, signs, and a variety of light industry, culture and education,and daily necessities.

PET/PBT Single Layer or Multi-layer Sheet Extrusion Line

This line is specially used for producing PP/PE/PS/ABS/PVC single layer or multi-layer sheet or plate, suitable in the fields of packaging, stationery, chemicals, construction, household appliances and so on.

Main technical data:

1. Usual sheet width: 700, 900, 1020, 1200, 1300, 1400, 1500, 1700, 1800, 2100, 2200mm

2. Usual sheet thickness: 0.5-2mm, 1.5-10mm, 6-20mm, 3-30mm

Extruder: Special screw structure, imported world-known thermocontrollers, electronics, hard gear face reducers to ensure high effective material extrusion capacity.

T -type die head: suitable compression ratio to ensure uniform flow stability.

Three-roller calendar: According to the material properties, adopting vertical three-roller, oblique three-roller, horizontal three-roller calendar. Internal roller temperature control using a unique flow channel, so that the stability of uniform distribution roller. The independent oil temperature control for three roller to ensure more stable and exact control.

Cooling frame: According to product specifications, configurations with different specifications of the stainless steel

cooling rollerEdge-cutting devices: Trimming can be divided into manual and automatic, three-dimensional configuration tool adjustment device, width adjustable.

Cut off machine: Saw cutting or knife cutting, thin type and non-friable type sheet generally usually knife cut, adopted high-quality alloy cutting tools, sharp and durable.

FEATURES AT A GLANCE

Right elevation

Left elevation

Front elevation

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

|

|

1

|

Power

|

132KW

|

|

|

|

2

|

Apply power supply

|

380 3 p/v / 50 hz

|

|

|

|

3

|

material use resin

|

PC PMMA PET

|

|

|

|

4

|

production line speed

|

2.5m/min

|

|

|

|

5

|

high extruder center

|

1000 mm

|

|

|

|

6

|

Mold size

|

to the customer's requirments

|

|

|

|

7

|

Forming method

|

rotational molding

|

|

|

|

8

|

The speed adjustment way

|

frequency control of motor speed

|

|

|

PRODUCT CONFIGURATION

SALES AND SERVICE NETWORK

Exhibition

Hot Searches