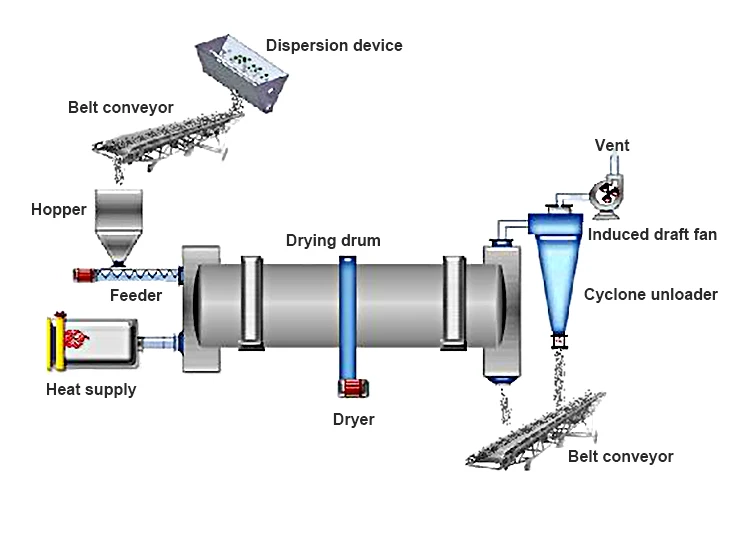

The heat sources of the dryer is from the combustion train. Because of the tilting device of dryer, when the materials enter into the body from the feeding device, i will flow to the bottom end under the infulence of gravity, as the drier is in an inclined position. This process makes the material well-distributed in the body, then ensure the heat exchange with the heat wind. After repeated cycle with this process, the moisture content will be dried and discharged from the dryer.

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Dryer

-

Application:

-

Mining Processing

-

Inclination:

-

3-5°

-

Highestintake temperature:

-

700/800℃

-

Color:

-

Customerized

-

MOQ:

-

1 set

-

Quality:

-

100% Test

-

Price:

-

Competitive(Can Negotiable)

-

After-sales service:

-

Technical Support

-

Certificate:

-

ISO9001

Quick Details

-

Weight (KG):

-

8000

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Changyi

-

Product name:

-

Dryer

-

Application:

-

Mining Processing

-

Inclination:

-

3-5°

-

Highestintake temperature:

-

700/800℃

-

Color:

-

Customerized

-

MOQ:

-

1 set

-

Quality:

-

100% Test

-

Price:

-

Competitive(Can Negotiable)

-

After-sales service:

-

Technical Support

-

Certificate:

-

ISO9001

Product Description

Jiangxi Changyi dryer is widely used in various industries for drying raw materials such as slag, river sand, clay, coal, iron powder, limestone, phosphogypsum, dry powder mortar and other mixtures, dry mixed mortar and yellow sand in the construction industry, as well as chemical, casting, and organic fertilizer (chicken manure, pig manure, etc.) industries.

Features of Dryer

1.Our dryer adopts new Spreading plate device, which has guidance, flow, material functions;

2.It can make the material contained in the dryer radial cross-section to full uniform, the material will become thin and all;

3.The state of the heat flow entirely, to achieve the purpose of making full use of the heat;

4.Our dryer chooses reasonable operating parameters, coal consumption and power consumption of general baked dry machine more than 10-15%,one machine yields above 10-15%;

5.It has been widely used in the cement and mineral processing enterprise.

Working Principle

Technical Parameters

|

Model

|

Inclination(°)

|

Speed(r/min)

|

Highest intake temperature(℃)

|

Power(kw)

|

Production(t/h)

|

|

φ600×6000

|

3-5

|

3-8

|

700

|

3

|

0.5-1.5

|

|

φ3000×25000

|

3-5

|

1.5-5

|

800

|

75

|

32-40

|

Note: Data only for reference, according to customer requirements for design and production.

Packaging&Shipping

Hot Searches