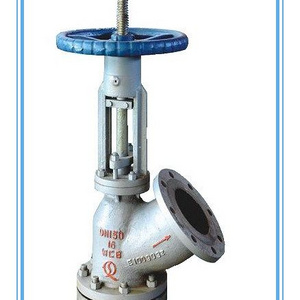

Bottom Drain Valve

Min. Order: 1 Piece

-

Transport Package:

-

Wooden Box

-

Specification:

-

DN50~DN500

-

Trademark:

-

Quanshun

- Product Details

- {{item.text}}

Quick Details

-

Origin:

-

Zhengzhou China

-

Media:

-

Water

-

Temperature:

-

High Temperature

-

Actuator:

-

Manual

-

Material:

-

Carbon Steel Stainless Steel

-

Structure:

-

Through Way Globe Valve

-

Sealing Form:

-

Gland Packings Globe Valve

-

Stem Thread Position:

-

Outside Screw Stem Globe Valve

-

Application:

-

Plunger Type Globe Valve

-

Standard:

-

DIN GB ANSI

-

Payment:

-

L/C T/T

-

Export Port:

-

QINGDAO , SHANGHAI, TIANJING

-

Output:

-

200PCS/Month

-

Model NO:

-

QsFb545Y-150

Quick Details

Bottom Drain valve (referred to Tank valve, Angle bottom valve, Bottom drain valve, Flush mount valve,tank bottom angle valve etc) are designed to provide drainage and dead space free shut off for reactors, vessels, autoclaves and storage tanks. Both inside vesel opening and inside valve opening can be supplied.

The dead space free shutoff is accomplished by placing the valve seat flush with the bottom of the vessel. This eliminates any buildup of product within the vessel nozzle itself.

The series of tank drain valve has two constructions: Y-type & angle type. According to the actual operating condition, the dumping entry has two types: pipe-connecting and flat bottom. If needed ,special surface treatment on the whole valve makes the surface hardness more than HRC 60, this can ensure the sealing reliability and avoid scarring. Moreover, a rotation-resistant device is set to ensure that the valve stem only has straight line motions, and no revolving motions. The driving manners of the valve include hand driving, electric ,driving, pneumatic and gear driving. Both rising disc type (the valve is opened into tank) and lowering disc type (the valve is opened into valve) can be designed.

BENEFITS

1.This range of manual control bottom drain valve is manufactured in y type integrated structure;

2. Short stroke for open/close operation;

3.lowering disc type (the valve is opened into valve) can be designed if needed.

4.The sealing surface of the valve seat and the valve disc is made of over laying cemented carbide or painted with tungsten carbide. The auxiliary line sealing guarantee the reliability of the sealing performance.

5. Crust breaking for disc rising type;

6.Disc is designed as external disc.

TECHNICAL SPECIFICATION :

Size: DN50-DN350

Pressure: PN10-PN16

Body Material: WCB

Connection Type:Flange

APPLICATION:

Alumina Refinery

Chemical Industry