Aluminum:

Lightweight, Strong, And Corrosion-Resistant, Making It an Ideal Choice for Mechanical Components.

Material Selection:

AL2024 / AL5052 / AL6061 / AL6063 / AL6082 / AL7075(customize)

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

industry,auto,construction...

-

Commodity:

-

A356 T6 alloy aluminum casting

-

Certificated:

-

ISO/TS16949

-

Material:

-

Aluminum

-

Dimensions:

-

Various as required

-

Standard:

-

DIN,BS,ASTM,GOST,ISO

-

Machined:

-

tough machined and fine machined

-

Process:

-

Casting. Deburring .Drilling .threading

-

Service:

-

OEM ODM Customised

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OEM

-

Model Number:

-

custom, A356 T6

-

Application:

-

industry,auto,construction...

-

Commodity:

-

A356 T6 alloy aluminum casting

-

Certificated:

-

ISO/TS16949

-

Material:

-

Aluminum

-

Dimensions:

-

Various as required

-

Standard:

-

DIN,BS,ASTM,GOST,ISO

-

Machined:

-

tough machined and fine machined

-

Process:

-

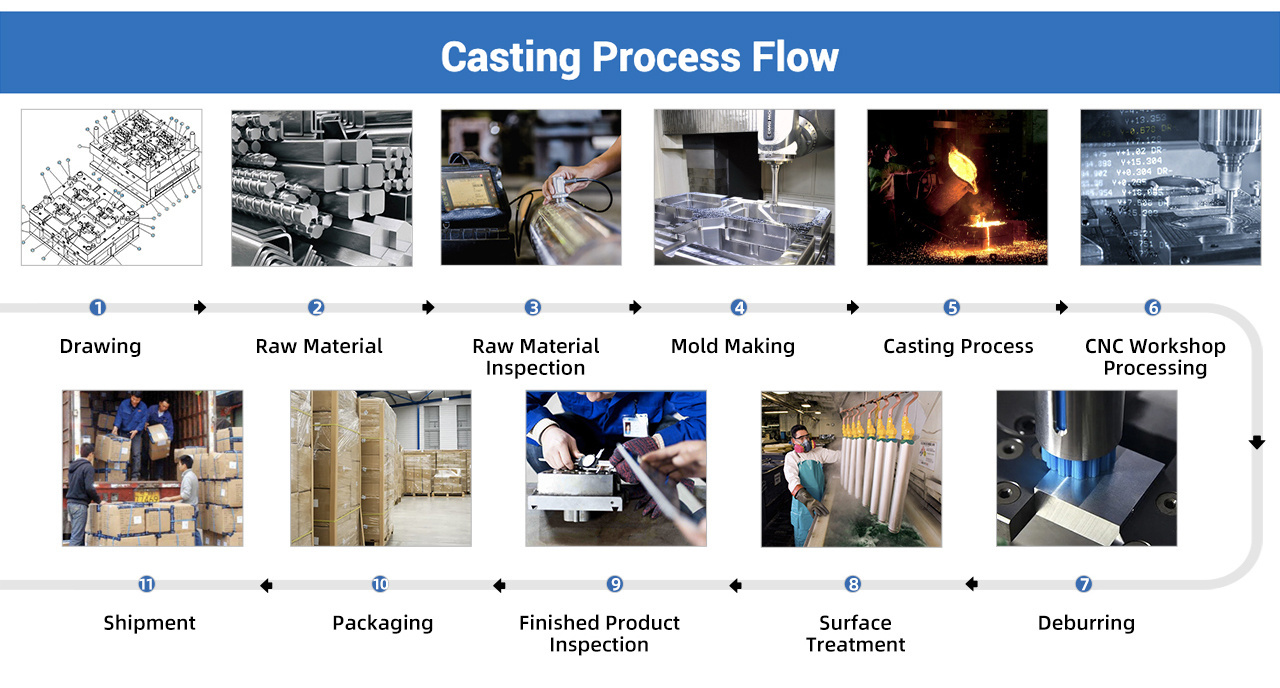

Casting. Deburring .Drilling .threading

-

Service:

-

OEM ODM Customised

China Stainless Steel cast aluminum die casting/sand casting gravity casting process products

Product Paramenters

|

Product name

|

investment casting

|

|

Surface treatment

|

machining

|

|

Material

|

316/304/Alloy steel

|

|

Process

|

Casting +Machining(if Need)+surface Treatment+Assembly

|

|

Color

|

As required

|

|

Quality Control

|

100% Inspected /ISO9001 System

|

|

Packing

|

Paper box

|

|

Special process

|

Assemble

|

|

Service

|

OEM\ODM

|

Technical Support

Pusher is professional at independent development and design. Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D softwares. We are able to design, develop,produce and deliver your PO according to your drawings, samples or just an idea. Dural control of standard products and OEM products.

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Product Display

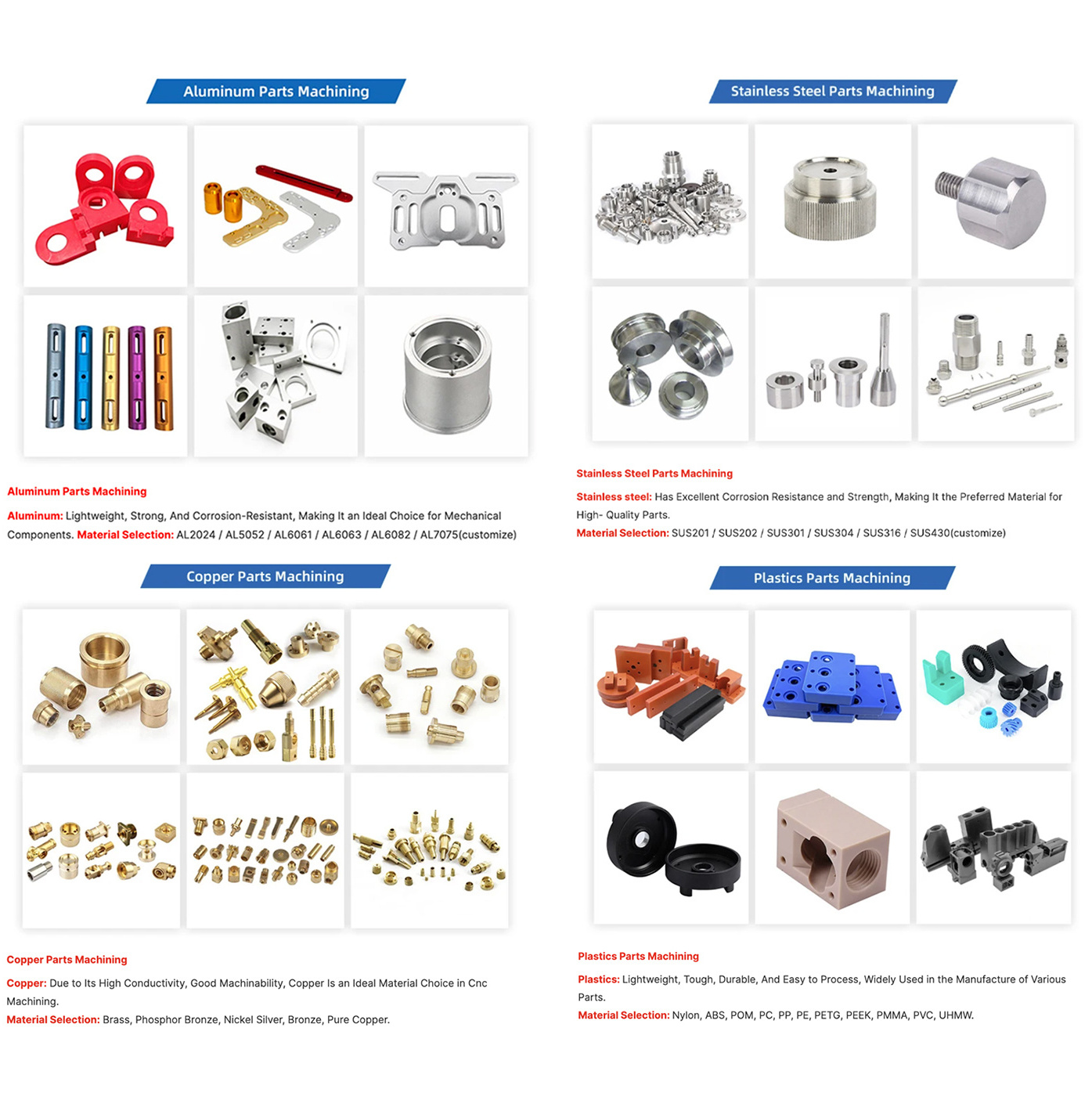

Aluminum Parts Machining

Stainless Steel Parts Machining

Stainless steel:

Has Excellent Corrosion Resistance and Strength, Making It the Preferred Material for High- Quality Parts.

Material Selection:

SUS201 / SUS202 / SUS301 / SUS304 / SUS316 / SUS430(customize)

Copper Parts Machining

Copper:

Due to Its High Conductivity, Good Machinability, Copper Is an Ideal Material Choice in Cnc Machining.

Material Selection:

Brass, Phosphor Bronze, Nickel Silver, Bronze, Pure Copper.

Plastics Parts Machining

Plastics:

Lightweight, Tough, Durable, And Easy to Process, Widely Used in the Manufacture of Various Parts.

Material Selection:

Nylon, ABS, POM, PC, PP, PE, PETG, PEEK, PMMA, PVC, UHMW.

Surface Treatment

CNC Machined Parts Surface Treatment.

(1) Physical surface treatment:

sandblasting, wire drawing, shot blasting, polishing, rolling, polishing, brushing, spraying,

painting, powder spraying, silk screen printing, pad printing, water transfer printing, electrophoresis, etc.

painting, powder spraying, silk screen printing, pad printing, water transfer printing, electrophoresis, etc.

(2) Chemical surface treatment:

bluish blackening, phosphating, pickling, electroless plating, TD treatment, QPQ treatment, carburizing, nitriding, chemical oxidation, passivation, etc.

(

3) Electrochemical surface treatment:

anodic oxidation, hard anodic oxidation, electrolytic polishing, electroplating, etc.

(4) Modern surface treatment:

chemical vapor deposition CVD, physical vapor deposition PVD, ion implantation, ion plating, laser surface treatment, etc.

Applications

Equipment

Hot Searches