Adopting PLC and pneumatic cylinder, it can work either together with whole production line or individually.

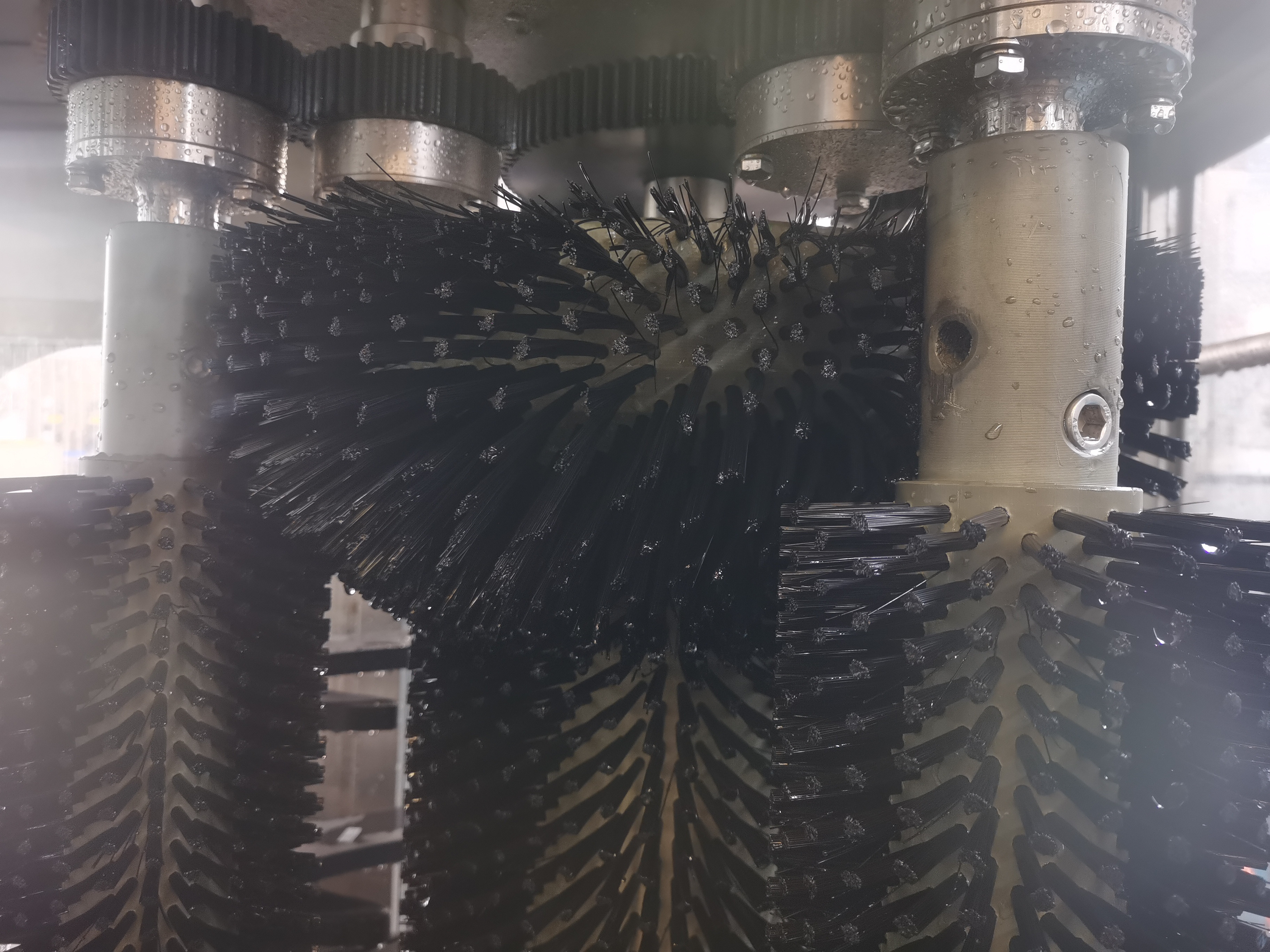

Decapper head does not hurt cap and bottle mouth at all. So, cap can be re-used.

Capacity is adjustable. It is compatible with a wide range of bottle height and cap diameter.