- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Weight:

-

4000 kg

-

Use:

-

Metal Roofing Equipment

-

Product name:

-

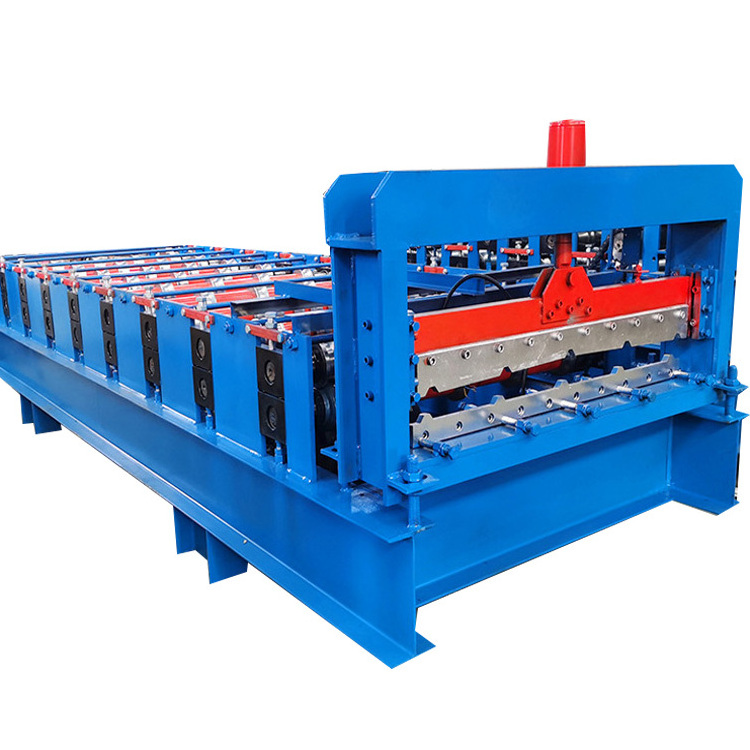

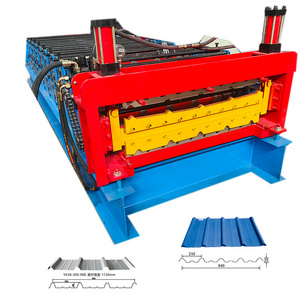

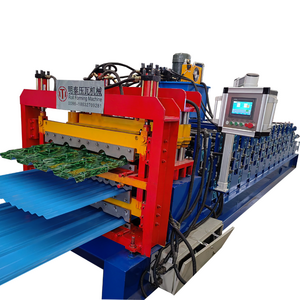

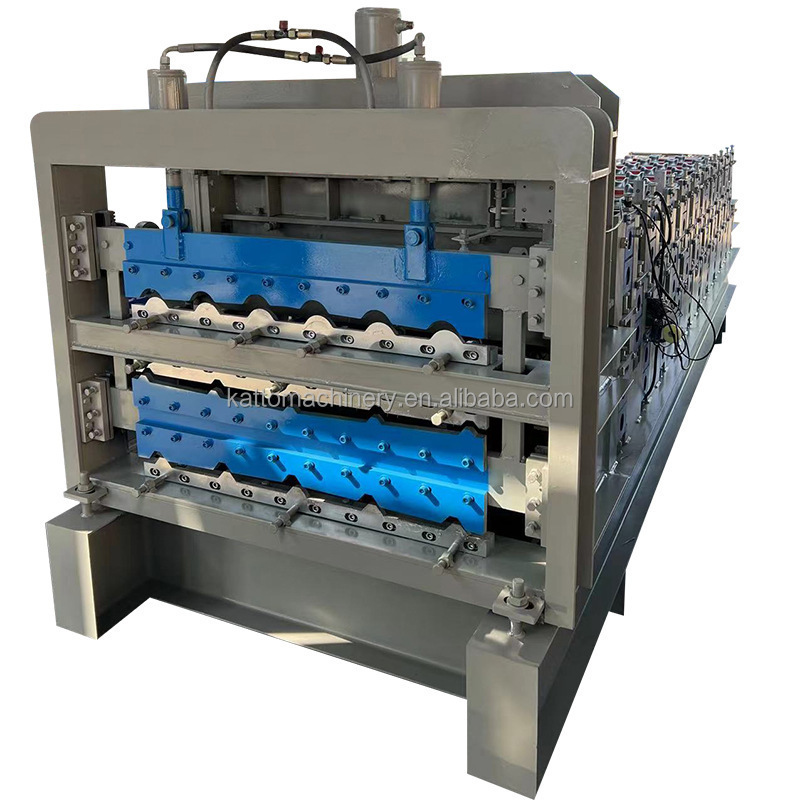

Roof Sheet Forming Machine

-

After-sales Service Provided:

-

Engineers

-

Usage:

-

Steel Construction

-

Name:

-

Glazed Roof Tile Production Line

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Keywords:

-

Colored Steel Roof Making Machine

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Weight:

-

4000 kg

-

Use:

-

Metal Roofing Equipment

-

Product name:

-

Roof Sheet Forming Machine

-

After-sales Service Provided:

-

Engineers

-

Usage:

-

Steel Construction

-

Name:

-

Glazed Roof Tile Production Line

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Keywords:

-

Colored Steel Roof Making Machine

Products Description

Automatic tile forming machine

The CNC automatic tile pressing machine is composed of discharging, forming and post-forming cutting. The products produced are flat and beautiful in appearance, uniform in paint pattern, high in strength and durable in use. They are widely used in industrial and civil buildings, such as workshops, warehouses, garages, , gymnasiums, exhibition halls, theaters and other room surfaces and walls. Its components include: complete machine, PLC computer control system, hydraulic pump station system, and automatic post-shearing system. Features: The color steel plate equipment adopts high-level automatic control software to realize production information management. The automation control system of the whole unit adopts a highly integrated network, which makes the performance of the automation system more superior. The color steel tile equipment also has the advantages of operation, maintenance, maintenance, mechanical debugging, and easy mold replacement.

Features

1.Our machine can use galvanized steel sheet, colored armor plate or aluminum plate as the material plate. 2.Controlling by computer PLC display, operate is easy. Running is steady and reliable,endurable maintenance-free. 3.We can make and design will kinds of roll forming machine according to customer’s request.

Manufacturing Technique

|

No

|

Item

|

Data

|

|

1

|

Raw material width

|

1000-1200 mm

|

|

2

|

Sheet effective width

|

750-1000 mm

|

|

3

|

Raw material

|

Color steel sheet or galvanized steel sheet

|

|

4

|

Material thickness

|

0.3-0.8 mm or customized

|

|

5

|

Forming roller material

|

45# steel plated with chrome

|

|

6

|

Shaft diameter

|

70 mm

|

|

7

|

Forming roll station

|

8-16 steps

|

|

8

|

Main motor power

|

3 KW 4 KW 5.5 KW(according to type)

|

|

9

|

Hydraulic power

|

4 KW (according to type)

|

|

10

|

Control system

|

PLC control

|

Drawing of the cart

Decoiler:

Roof sheet corrugated roll forming machine load parts, decoiler loading frame we can offer different type can choose. standard type are manual,also can choose electric loading frame or hydraulic loading frame.

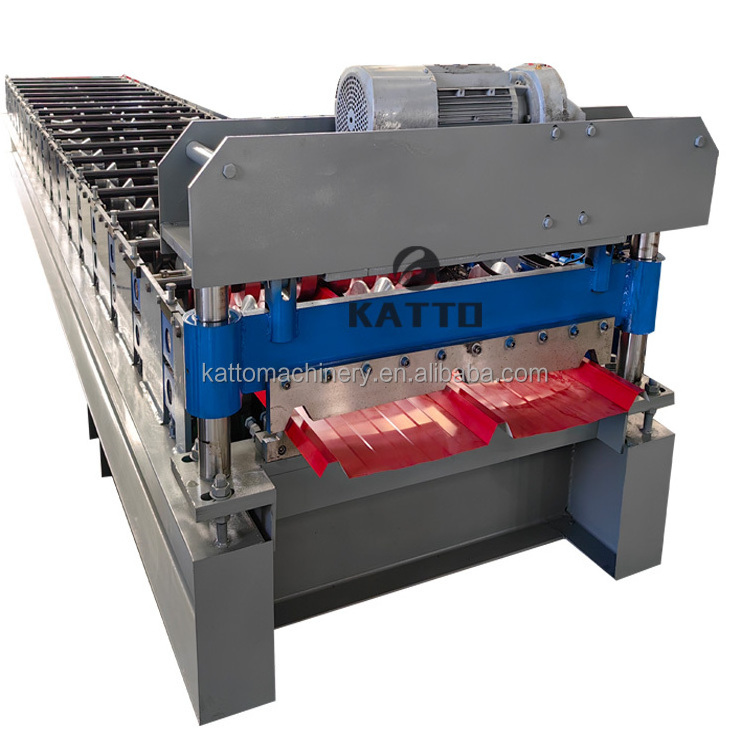

Tile forming machine:

Roof sheet corrugated roll forming machine adopts welded steel frame structure, it make sure roof sheet machine can operation more

stableAC frequency conversion motor reducer drive, chain transmission, roller surfaces polishing,

hard plating, heat treatment and chrome coating.

stableAC frequency conversion motor reducer drive, chain transmission, roller surfaces polishing,

hard plating, heat treatment and chrome coating.

Hydraulic Cutting:

Blade material: Cr12, heat treatment58 ℃-62 ℃

When cutting start to work, Hydraulic pump station excitation guide column working, drive blade cutting .

Because the cutting method is stable, metal plate cross section is neat.

When cutting start to work, Hydraulic pump station excitation guide column working, drive blade cutting .

Because the cutting method is stable, metal plate cross section is neat.

PLC Controler

It is to used to setting the cutting size with easy to operation

Roller

Roller Material: 45#steel

The roller material processing method :

1. Rough machining

2.Fine polishing

3.Heat treatment58 ℃-62 ℃

4.Cr12 hard chromium plating

The roller material processing method :

1. Rough machining

2.Fine polishing

3.Heat treatment58 ℃-62 ℃

4.Cr12 hard chromium plating

Shaft

Shaft Diameter: 70 mm

The roller and shaft won't scratch the board. It is long service life and durable.

The roller and shaft won't scratch the board. It is long service life and durable.

Hot Searches