- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

231-072-3

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JC

-

Model Number:

-

828AB

-

Type:

-

Two components

Quick Details

-

CAS No.:

-

250-68-38-6

-

Other Names:

-

epoxy resin ab glue

-

MF:

-

C15H16O2C2H7ONC3H5OCl

-

EINECS No.:

-

231-072-3

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JC

-

Model Number:

-

828AB

-

Type:

-

Two components

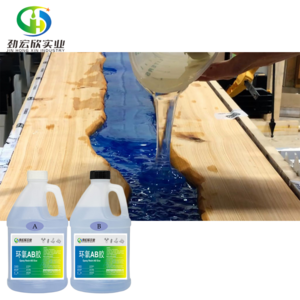

Features :

Epoxy resin 828AB can be cured under normal temperature and low temperature, with the feature of high hardness, good flowing property, natural defoaming, fast curing.

Application:

828AB can be widely used for carbon fiber prodsurfboard coating, lamp potting and mold filling, etc…

Properties before Hardening:

|

Part |

828A |

828B |

|

|

Color |

Transparent |

Transparent |

|

|

Viscosity (25 ℃ mpa·s ) |

6000-10000CPS |

250MAXCPS |

|

|

Mixing ratio |

A: B = 100:50(weight ratio) |

||

|

Specific gravity |

1.15 |

0.96 |

|

|

Hardening conditions |

25 ℃× 3H to 4H or 55 ℃× 30min (2 |

||

|

Usable time |

25 ℃× 15min (100g) |

||

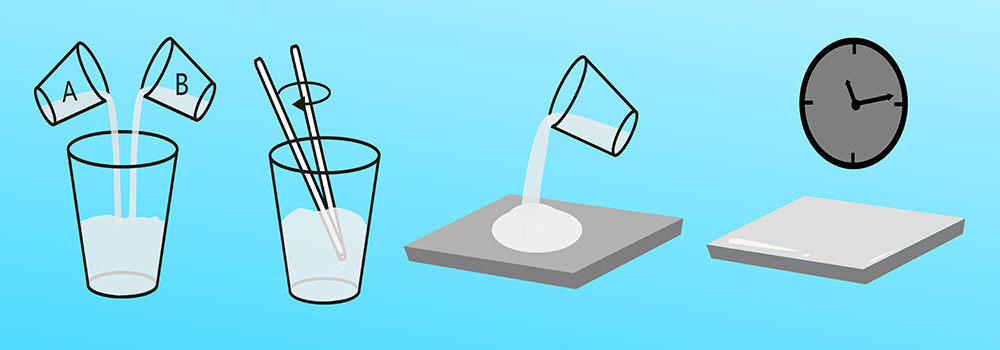

Operation:

1.Weigh A and B glue according to the given weight ratio into the prepared cleaned container, fully mixed the mixture again the container wall by clockwise, place it along for 3 to 5 minutes, and then it can be used.

2.Take the glue according to the usable time and dosage of mixture to avoid wasting. When the

temperature is below 15 ℃, please heat A glue to 30 ℃ first and then mix it to the B glue (A glue will be thicken in low temperature ); The glue must be sealed lid after use to avoid rejection

caused by moisture absorption.

3.When the relative humidity is higher than 85%, the surface of the cured mixture will absorb

moisture in the air, and form a layer of white mist in the surface, so when the relative humidity is higher than 85%, is not suitable for room temperature curing, suggest to use the heat curing.

Properties after Hardening :

|

Hardness shore D |

<90 |

|

Withstand voltage KV/mm |

22 |

|

Flexural strength Kg/mm2 |

28 |

|

Volume resistivity Ohm3 |

1x10 15 |

|

Surface resistance Ohmm2 |

5X10 15 |

|

Thermal conductivity W/M.K |

1.36 |