Conventional Wood/Coal/Gas heaters need large storage space for heating equipment, manual labor area and large storage area (for wood or Coal) whereas Electric Air Duct Heaters are smaller in size and can be implemented/used in small spaces.

- Product Details

- {{item.text}}

Quick Details

-

Applicable Industries:

-

Air heater,gas heater,water heater,plant,coal,offi

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BRIGHT

-

Dimension(L*W*H):

-

customized

-

Weight:

-

40 KG

-

Working Temperature Range:

-

20 - 500 ℃

-

Material:

-

other, 304 stainless steel,steel, carbon steel

-

Core Components:

-

Heating Element

-

Product name:

-

Process air duct heater with flanged inlet/outlet for high pressure

-

Usage time:

-

7000h

-

Material heating element:

-

high temperature alloy

-

Temperature raise rate:

-

10 degree Celsius per second during working

-

Thermal Efficiency:

-

More than 95%

-

Pressure:

-

MAX 0.6 Mpa

-

Max temperature:

-

500℃

-

Experience in Making:

-

18 Years

-

Optional:

-

air fan , temperature controller

Quick Details

-

Type:

-

Air Heater

-

Power Source:

-

Electric

-

Voltage:

-

220V,380V

-

Applicable Industries:

-

Air heater,gas heater,water heater,plant,coal,offi

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BRIGHT

-

Dimension(L*W*H):

-

customized

-

Weight:

-

40 KG

-

Working Temperature Range:

-

20 - 500 ℃

-

Material:

-

other, 304 stainless steel,steel, carbon steel

-

Core Components:

-

Heating Element

-

Product name:

-

Process air duct heater with flanged inlet/outlet for high pressure

-

Usage time:

-

7000h

-

Material heating element:

-

high temperature alloy

-

Temperature raise rate:

-

10 degree Celsius per second during working

-

Thermal Efficiency:

-

More than 95%

-

Pressure:

-

MAX 0.6 Mpa

-

Max temperature:

-

500℃

-

Experience in Making:

-

18 Years

-

Optional:

-

air fan , temperature controller

Products Description

Electric Air Duct Heaters

Electric Air Duct Heaters uses electric power as energy to convert electric energy into heat energy via electric heating element. Hot Air is circulated in the system through Air Blower, and circulating Air heating is used. Electic Air Duct heaters are energy efficient alternative to conventional Wood/Coal/Gas heaters.

Conventional Wood/Coal/Gas heaters need large storage space for heating equipment, manual labor area and large storage area (for wood or Coal) whereas Electric Air Duct Heaters are smaller in size and can be implemented/used in small spaces.

Conventional Wood/Coal/Gas heaters need large storage space for heating equipment, manual labor area and large storage area (for wood or Coal) whereas Electric Air Duct Heaters are smaller in size and can be implemented/used in small spaces.

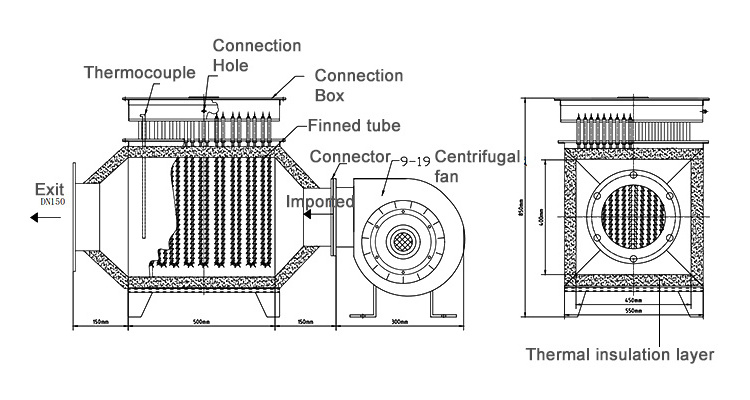

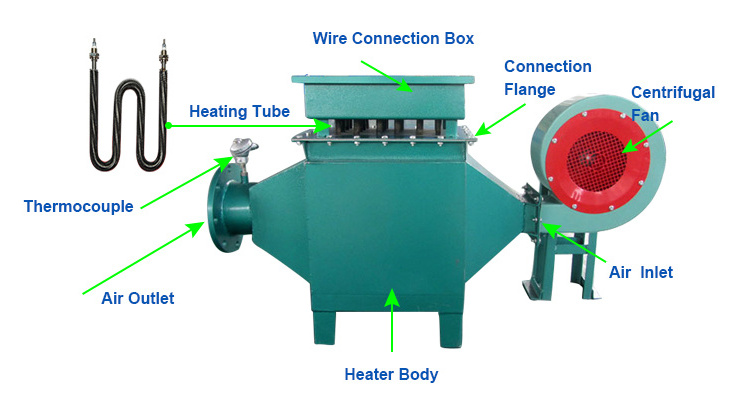

Composition structure

Sheath house ( steel alloy, stainless steel ,or other material as your design)

Finned heating elements

Thermal insulators for keeping air temperature

Wire connection box

Centrifugal fan

Thermocouple

Inlet/Outlet hole

Temperature controller

Fuse

Finned heating elements

Thermal insulators for keeping air temperature

Wire connection box

Centrifugal fan

Thermocouple

Inlet/Outlet hole

Temperature controller

Fuse

Product Paramenters

|

Temperature raise rate

|

10 degree Celsius per second during working

|

|

Heat efficient

|

more than 95%

|

|

Usage time

|

standard more than 10 years

|

|

Thermal insulation layer

|

50-100mm

|

|

Heating element

|

open coil, tubular, finned tubular

|

|

Tube diameter

|

6.5 / 8.5 / 10 / 13.5 / 16 mm

|

|

Tube material

|

Stainless steel: AISI 321 (1.4541) / AISI 316L (1.4404) / AISI 309 (1.4828)

|

|

|

Others: Incoloy 800 (1.4876) / Incoloy 825 (2.4858) / Inconel 600 (2.4816)

|

|

Specific coating

|

PTFE

|

|

Tube type

|

Sealed tube, seamless tube (on request)

|

|

Insulation

|

magnesia oxyde (Mg O)

|

|

Resistance wire

|

Nickel Chrome 80/20

|

|

Sealing material

|

Keeps out external moisture

|

|

Output insulation

|

Made of steatite ou corundumOutput insulation

|

|

Connecting box

|

Non ATEX connecting box, Explosion-proof connecting box

|

|

Accessories

|

Thermocouple Sensors, 3-phase motor, Control Panel, Stainless Steel Insulation Housing, Stainless Steel Support Plate and Corner

Posts, Single- and Three-Phase Wiring, 1" (25 mm) Insulation |

What we usually need

1) What's the initial temperature and needed heat temperature?

2) What's the air speed? m³/h or how big of the heating room?

3)

Whether the space contains corrosion?

4) Do you need Temperature controller cabninet?

5) What's the voltage?

Main Features

1) During heating, air max temperature can reach 500 degree Celsius or higher temperature, but the surface temperature of the sheath is just around 50 degree Celsius

2) Heat efficient is more than 95%

3) Temperature raise rate : 10 degree Celsius per second during working

4) The heating elements is made of high temperature alloy with good mechanical character

5) Usage time: standard more than 10 years

6) Clean air, small volume

7) Made as client design (OEM)

8) After reached the max temperate, the working wattage can reduce to half

9) The electric heating pipe is made of corrugated stainless steel strip, which increases the heat dissipation area and greatly improves the heat exchange efficiency.

10) Reasonable design of heater, small wind resistance, uniform heating, no high or low temperature dead angle.

11) Double protection, good safety performance. Temperature controllers and fuses are installed on the heater, which can be used to control the temperature of the air in the air duct and work without wind, so as to ensure that there is no mistake.

3) Temperature raise rate : 10 degree Celsius per second during working

4) The heating elements is made of high temperature alloy with good mechanical character

5) Usage time: standard more than 10 years

6) Clean air, small volume

7) Made as client design (OEM)

8) After reached the max temperate, the working wattage can reduce to half

9) The electric heating pipe is made of corrugated stainless steel strip, which increases the heat dissipation area and greatly improves the heat exchange efficiency.

10) Reasonable design of heater, small wind resistance, uniform heating, no high or low temperature dead angle.

11) Double protection, good safety performance. Temperature controllers and fuses are installed on the heater, which can be used to control the temperature of the air in the air duct and work without wind, so as to ensure that there is no mistake.

Applications

1) Heat treating

2) Air drying operations

3) Air handling equipment

4) Forced air comfort heating

5) Core drying

6) Fan coils

7) Booster air heater

8) Air pre-heating

9) Terminal reheating

10) Multizone reheating

11) Heat pump auxiliary systems

12) Return air heating

13) Resistor load banks

2) Air drying operations

3) Air handling equipment

4) Forced air comfort heating

5) Core drying

6) Fan coils

7) Booster air heater

8) Air pre-heating

9) Terminal reheating

10) Multizone reheating

11) Heat pump auxiliary systems

12) Return air heating

13) Resistor load banks

14) Annealing

15) In Air Handling Units

16) Heat treating

17) Forced air comfort heating

18) Booster air heater

19) Air drying operations

20) Core drying

21) Air pre-heating

22) Air handling equipment

23) Terminal reheating

24) Multizone reheating

25) Heat pump auxiliary systems

26) Resistor load banks

15) In Air Handling Units

16) Heat treating

17) Forced air comfort heating

18) Booster air heater

19) Air drying operations

20) Core drying

21) Air pre-heating

22) Air handling equipment

23) Terminal reheating

24) Multizone reheating

25) Heat pump auxiliary systems

26) Resistor load banks

Packaging and Delivery

Packaging

Brown box with shock-proof sponge. Custom package is available, but the price need to be negotiated.

Delivery

FCA shipping method. Generally most countries needs about 7-15 days, detailed shipping time will be according to the address and other force majeure factors.

Delivery

FCA shipping method. Generally most countries needs about 7-15 days, detailed shipping time will be according to the address and other force majeure factors.

About Bright

Hot Searches