- Product Details

- {{item.text}}

Quick Details

-

Printing Type:

-

Inkjet Printer

-

Weight (KG):

-

0.5

-

Place of Origin:

-

Japan

-

Product name:

-

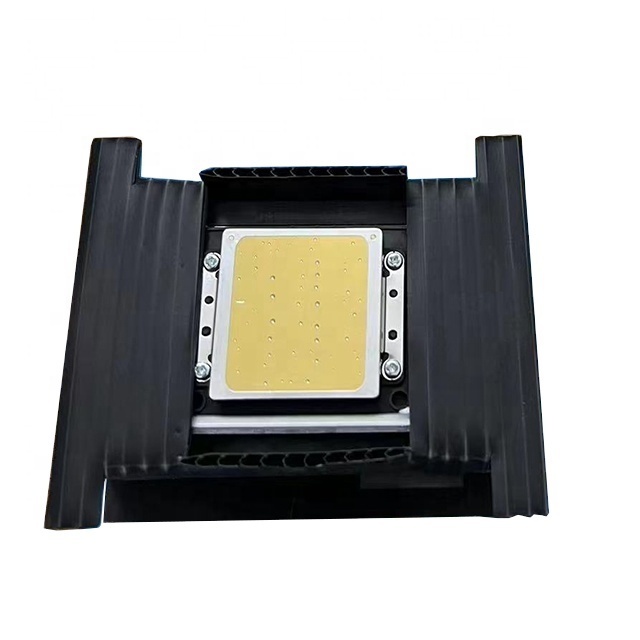

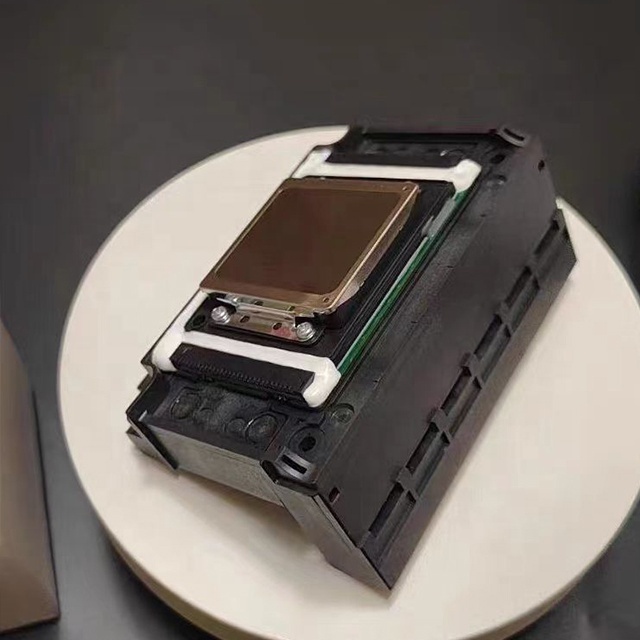

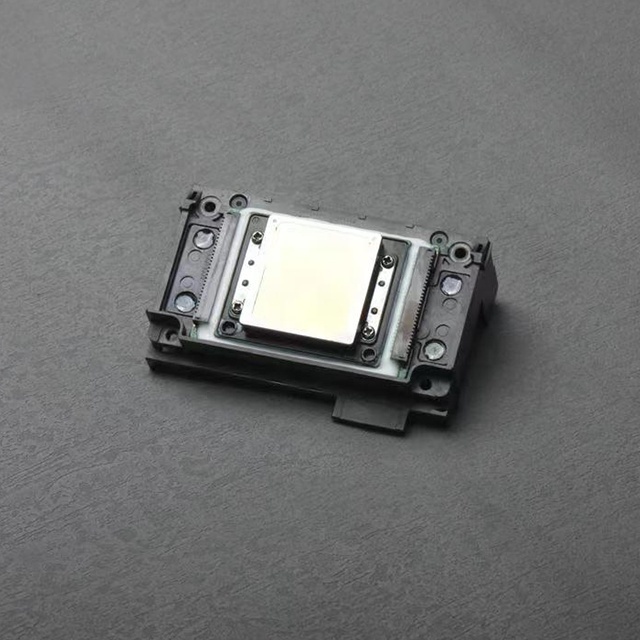

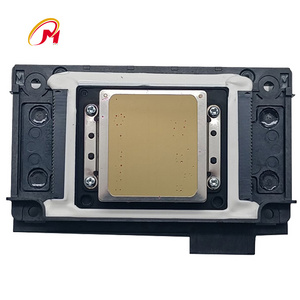

Brand New XP600 Print Head DX11 DTF Printer head

-

Used for:

-

Eco-solvent/UV/Pigment printer

-

MOQ:

-

1PCS

-

Delivery Time:

-

3-7working Days

-

Payment Terms:

-

TT Westerm Union MomeyGram Paypal

-

Package:

-

Normal Packing

-

SHIPPING:

-

Express

-

Quality:

-

Excellent

-

Ink type:

-

AQ Ink

Quick Details

-

Condition:

-

New

-

Type:

-

Print Head

-

Use:

-

all kinds of printer

-

Printing Type:

-

Inkjet Printer

-

Weight (KG):

-

0.5

-

Place of Origin:

-

Japan

-

Product name:

-

Brand New XP600 Print Head DX11 DTF Printer head

-

Used for:

-

Eco-solvent/UV/Pigment printer

-

MOQ:

-

1PCS

-

Delivery Time:

-

3-7working Days

-

Payment Terms:

-

TT Westerm Union MomeyGram Paypal

-

Package:

-

Normal Packing

-

SHIPPING:

-

Express

-

Quality:

-

Excellent

-

Ink type:

-

AQ Ink

Product Overview

Brand New XP600 Print Head DX11 DTF Printer head High Printing Quality XP600 PrintHead

Brand New XP600 Print Head DX11 DTF Printer head High Printing Quality XP600 PrintHead

has cheap price and high print resolution, suitable for

Eco-solvent inkjet printer, UV

inkjet printer

, DTF

inkjet printer

etc

Products Description

Product Paramenters

|

Printer Technology

|

Brand New XP600 Print Head DX11 DTF Printer head High Printing Quality XP600 PrintHead

|

|

|

|||

|

Parameters

|

|

|

|

|||

|

Ink type

|

AQ inks

|

|

|

|||

|

WidthxDepthxHeight

|

84.9*57.2*42.6mm

|

|

|

|||

|

Weight

|

60g

|

|

|

|||

|

Number of nozzle

|

1080

|

|

|

|||

|

Nozzle pitch(inch)

|

180

|

|

|

|||

|

Nozzle rows

|

6

|

|

|

|||

|

Max. number of colour inks

|

6 colors(180dpi/color)

|

|

|

|||

|

Nozzle Resolution

|

180 npi /row 360 npi/2 rows

|

|

|

|||

|

Effective print width

|

25.4mm

|

|

|

|||

|

Droplet ejection performance

|

46(kHz) or 11.52(kHz)

|

|

|

|||

|

Ink drop Volume

|

4.5-9-20-40 pl

|

|

|

|||

|

Viscosity range

|

3-5 mPa.s

|

|

|

|||

Packing

Maintenance tips

1. Lack of ink

⑴. Check if the ink cartridge is lack of ink, do not tighten the ink cartridge cover

⑵. Check whether the ink tube clamp is open

⑶. Check whether the ink damper is installed correctly

⑷. Check whether the print head is aligned with the ink caps

⑸. Check whether the waste ink pump is working normally

If there is no problem, the print head channel may be blocked, and the print head needs to be cleaned in time

2.Cleaning

⑴. Use the head cleaning and ink loading function in the control software for automatic cleaning.

After each cleaning and ink loading, you need to print the head status to check the cleaning effect. This operation until the

nozzle status is well.

⑵. If the effect of head cleaning and ink loading are not good,do ink pumping cleaning.

When the carriage is in the initial position, use a syringe and tube to connect to the waste ink tube to forcefully extract about

5ml of ink (note that during the ink pumping process,do not allow the inner cylinder of the syringe to rebound, which will cause

color mixing in the head.) If the ink stack caps are not tightly sealed during the ink pumping process, you can gently move the

carriage to ensure a good seal between the head and the caps. After the ink is drawn, use the head cleaning and ink loading

function again.

⑶. Injecting and pumping cleaning: remove the carriage, place a non-woven fabric under the head, close ink tube clamp, pull out

the ink sac, and connect the syringe with cleaning liquid to the ink channel of the head by the tube, and push the syringe with

proper pressure, until the head sprays a complete thin line vertically.

⑷. Print cleaning: Use "cleaning liquid" to replace the ink that has blocked channel, print the pure color block of that color,

and replace the original ink when the channel block is cleared.

3.Maintenance

⑴.If the printer is not used for a short period of time (1-2 days), simple maintenance of the print head is required. The

maintenance methods and steps are as follows:

After the printer is used, carry out ink loading and head cleaning, and print the head status. After the print head is in good

condition, clean the print head with cleaning fluid, drop a little moisturizing liquid on the ink stack cap, and then turn off the

machine to return the carriage to the initial position. After checking the alignment of the print head and the ink stack cap, the

maintenance can be completed.

⑵.If the printer is not used for a long time (1-2 months), professional maintenance of the print head is required. The maintenance

methods and steps are as follows:

1. Remove the head from the printer according to the correct method, and clean the residual ink stains;

2. Use head cleaning function to clean the print head

3. Inject special head maintenance liquid into each ink channel of the head

4. Use non-woven fabric and stretch film to seal the print head and store it in a cool place.

⑴. Check if the ink cartridge is lack of ink, do not tighten the ink cartridge cover

⑵. Check whether the ink tube clamp is open

⑶. Check whether the ink damper is installed correctly

⑷. Check whether the print head is aligned with the ink caps

⑸. Check whether the waste ink pump is working normally

If there is no problem, the print head channel may be blocked, and the print head needs to be cleaned in time

2.Cleaning

⑴. Use the head cleaning and ink loading function in the control software for automatic cleaning.

After each cleaning and ink loading, you need to print the head status to check the cleaning effect. This operation until the

nozzle status is well.

⑵. If the effect of head cleaning and ink loading are not good,do ink pumping cleaning.

When the carriage is in the initial position, use a syringe and tube to connect to the waste ink tube to forcefully extract about

5ml of ink (note that during the ink pumping process,do not allow the inner cylinder of the syringe to rebound, which will cause

color mixing in the head.) If the ink stack caps are not tightly sealed during the ink pumping process, you can gently move the

carriage to ensure a good seal between the head and the caps. After the ink is drawn, use the head cleaning and ink loading

function again.

⑶. Injecting and pumping cleaning: remove the carriage, place a non-woven fabric under the head, close ink tube clamp, pull out

the ink sac, and connect the syringe with cleaning liquid to the ink channel of the head by the tube, and push the syringe with

proper pressure, until the head sprays a complete thin line vertically.

⑷. Print cleaning: Use "cleaning liquid" to replace the ink that has blocked channel, print the pure color block of that color,

and replace the original ink when the channel block is cleared.

3.Maintenance

⑴.If the printer is not used for a short period of time (1-2 days), simple maintenance of the print head is required. The

maintenance methods and steps are as follows:

After the printer is used, carry out ink loading and head cleaning, and print the head status. After the print head is in good

condition, clean the print head with cleaning fluid, drop a little moisturizing liquid on the ink stack cap, and then turn off the

machine to return the carriage to the initial position. After checking the alignment of the print head and the ink stack cap, the

maintenance can be completed.

⑵.If the printer is not used for a long time (1-2 months), professional maintenance of the print head is required. The maintenance

methods and steps are as follows:

1. Remove the head from the printer according to the correct method, and clean the residual ink stains;

2. Use head cleaning function to clean the print head

3. Inject special head maintenance liquid into each ink channel of the head

4. Use non-woven fabric and stretch film to seal the print head and store it in a cool place.

Hot Searches