- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

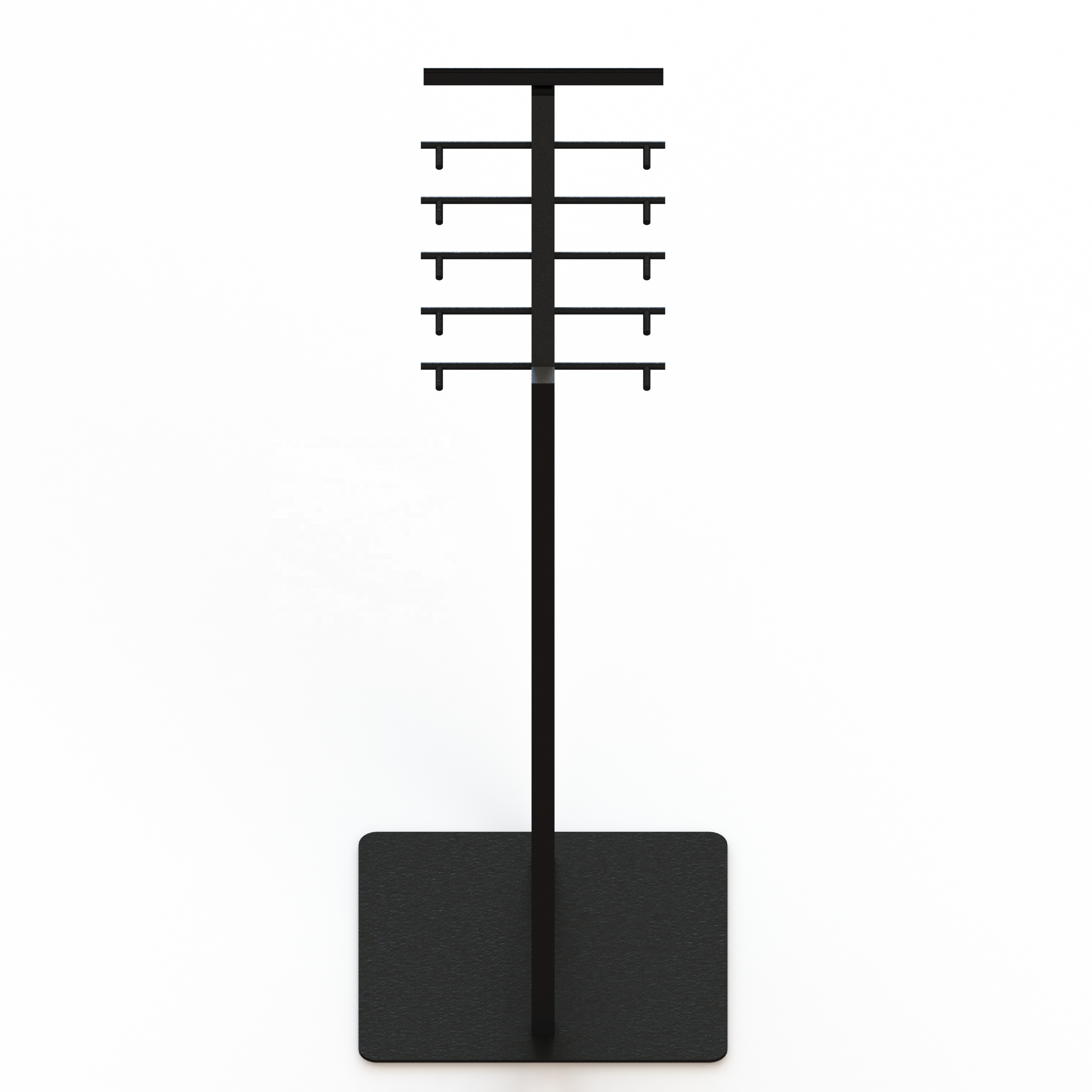

One Side Wooden Flooring Metal Display Stand

-

Function:

-

Store

-

Usage:

-

For Wood Flooring

-

Material:

-

Metal Iron

-

Application:

-

Save Space

-

Feature:

-

Eco-friendly

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SDI

-

Model Number:

-

3HD16

-

Product name:

-

One Side Wooden Flooring Metal Display Stand

-

Function:

-

Store

-

Usage:

-

For Wood Flooring

-

Material:

-

Metal Iron

-

Application:

-

Save Space

-

Feature:

-

Eco-friendly

One Side Wooden Floor Metal Display Stand With Wire Hooks.

10 Hardwood Tiles Display Rack for tiles size 810x133, 910x153mm.

Against The Wall Mount Hardwoods Storage Rack is a space saving are powder coated to ensure a long-lasting durable finish.

Industrial Metal Display Rack Systems is commonly found in store.

-

Metal Tube with strong welded.

-

10 Wire Hooks hold 153x910mm Wood Board or customized size .

-

Knock-down construction is easy installation.

|

Feature: |

1inch Tube Frame with Wire Hooks Display Stand

|

|

Structure: |

Metal Tube and Wire Hooks Welded Sturdy Construction Base is knock-down construction

|

|

Sign : |

Metal Clip Sign Holder and One Side Sign

|

|

Mobility: |

Light weight easy moving

|

|

OEM: |

Customized requirements are accepted

|

1.

We have metal workshop and powder coating line,

With about 10 years professional production manufacture experience, the advanced machines and skillful workers, We always insist on making the best quality products for you.

2. We have safe and unique production processes, strict quality control system.

3. Good service and high quality can ensure us to establish long-term trade relationship with customers.

4. Our product can be used to display food, beverage,shoes, toys and so on.

Design:

Solid Hard Timber Wood Board Metal Industrial Display Rack can display 8,10,12 or more wooden plank.

With Front Brochure Holder, Low front and high back design Hardwood Flooring Display Stand can maximize the display of all Hardwood Tiles .

First, our structural design considers how we can save transportation costs. Generally we will use Knock Down or Foldable Structure .

Second, when we make sample, we have a drop test to make sure our design and packing is safety.

Packing material:

- Poly bag for hardward or smaller parts

- EPE , foam , such as for packaging and protection of safety during the transportation of products not subject to wear and tear

- Double c orrugated box for unit

- Non fumigation pallets for LCL

|

|

|

We are focus on the features of Display Rack to march your real demand, Some of the most common features include lockable wheels or casters, adjustable height, movable hooks, and internal shelving.

We understand that shipping cost is expensive for display rack, when we design for new case, there are lots of ways to save cost which you may find helpful.

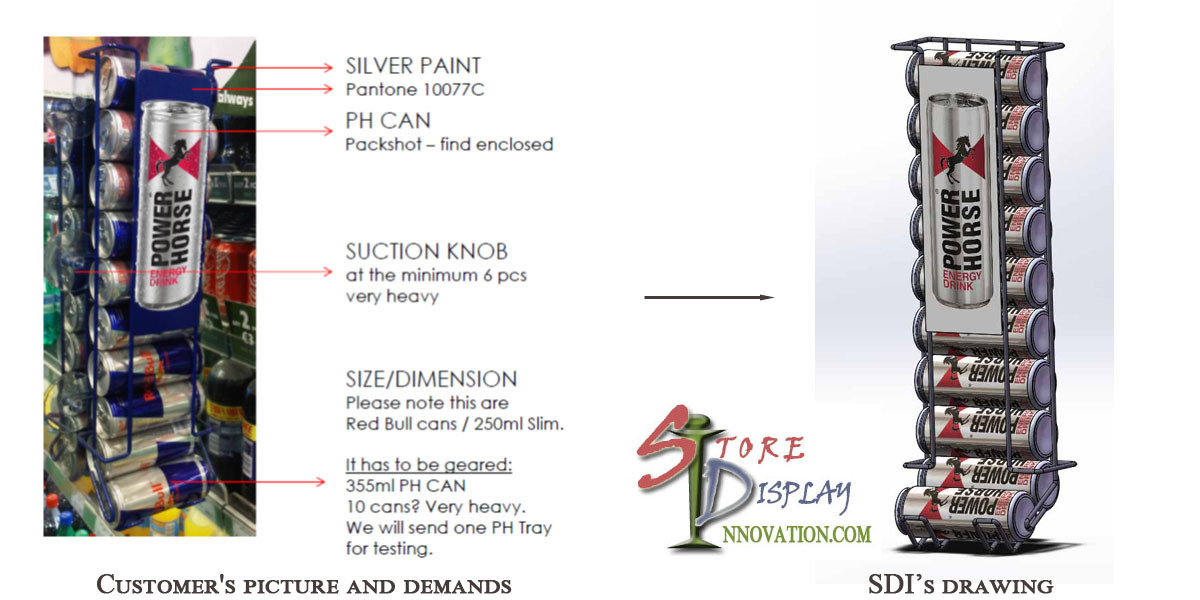

Step 1 : Making confirmed a quotation according to customers' requirements (1-2 working days)

Step 2 : Making the technical drawings of the product according to the confirmed a design (5-7 working days)

Step 3 : Making a sample for customer confirmation (15-20 working days)

Step 4 : Start manufacturing;(30-45 working days)

Step 5 : Assemble the product and take photos

Step 6 : Shipping package