- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

2500 mm

-

Backgauge Travel (mm):

-

20 - 500 mm

-

Throat Depth (mm):

-

150 mm

-

Brand Name:

-

CNCColgar

-

Power (kW):

-

5.5 kW

-

Weight (KG):

-

4500 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220/230/380/415v, 220V/380V/400V

-

Dimension(L*W*H):

-

3220 *1420* 1500mm

-

Year:

-

2023

-

Warranty of core components:

-

24 months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Size:

-

3220 *1420* 1500mm

-

Weight:

-

3.15T

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

Thailand

-

Application:

-

Industrial Metal Cutting

-

Type:

-

Hydraulic Cutting Tools

-

Product name:

-

Hydraulic Cnc Shearing Machine

Quick Details

-

Max. Cutting Width (mm):

-

2500

-

Max. Cutting Thickness (mm):

-

4 mm

-

Shearing Angle:

-

1°30

-

Blade Length (mm):

-

2500 mm

-

Backgauge Travel (mm):

-

20 - 500 mm

-

Throat Depth (mm):

-

150 mm

-

Brand Name:

-

CNCColgar

-

Power (kW):

-

5.5 kW

-

Weight (KG):

-

4500 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220/230/380/415v, 220V/380V/400V

-

Dimension(L*W*H):

-

3220 *1420* 1500mm

-

Year:

-

2023

-

Warranty of core components:

-

24 months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Size:

-

3220 *1420* 1500mm

-

Weight:

-

3.15T

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

Thailand

-

Application:

-

Industrial Metal Cutting

-

Type:

-

Hydraulic Cutting Tools

-

Product name:

-

Hydraulic Cnc Shearing Machine

Products Description

Hydraulic swing beam shear machine metal shear machine

1. The shearing machine is of metal plate welded structure, hydraulic transmission, and accumulator return stroke, easy operation, reliable performance, and nice appearance and standard NC controller.

2. Metal shears gap between blades is indicated by sign, for a handy and prompt adjustment.

3. Light alignment device and shearing stroke control device for easy and fast adjustment.

4. Worktable with rolling plate support balls to facilitate plate feeding, and to reduce scratch on plate and frictional resistance.

Hydraulic shearing machine main features:

1, German Siemens Motor can be optional

2, France Schneider electric can be optional

3, USA Sunny oil pump is optional

4, Material pressure cylinder, to ensure you the best leakproofness, without oil leak trouble

5, The oil cylinder is with mirror finished, also to reduce oil leak trouble

Metal shearing machine parameters:

Details Images

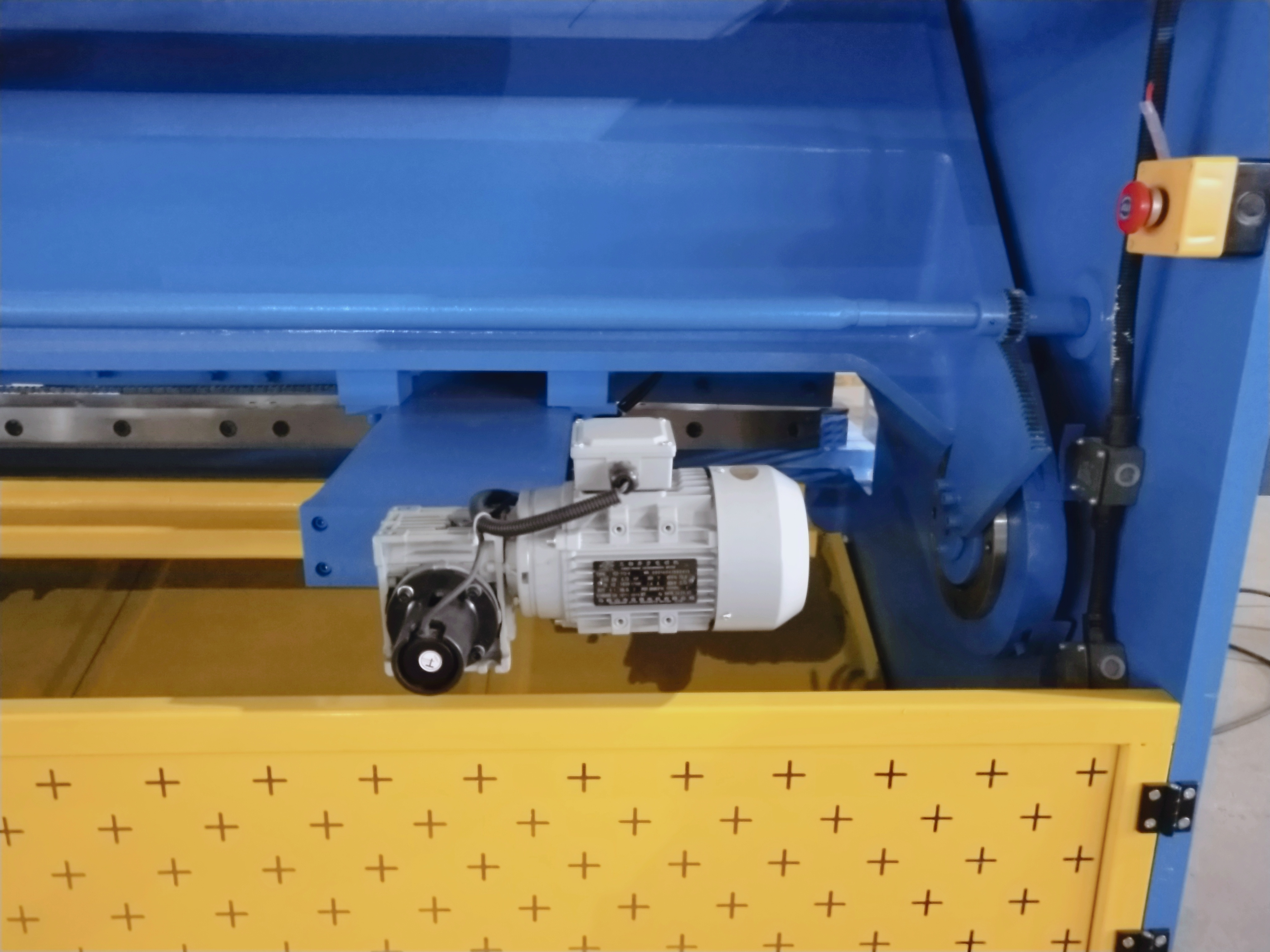

Back gauge & blade

ball screw linear guide, 9CrSi, 6CrW2Si.

Feeding table & Pneumatic Clamp

rolling balls, 10 pieces clamp for 2500mm shear

Shaft & gear E-stop button

made by wear resistant material

Back gauge motor

with precise Estun encoder for ESTUN E21 system

Siemens motor

Good for hyraulic system running

American sunny pump

precise pressure control

Backguage pneumatic support

Ensure the cutting precision and facilitate the removal of the sheet.

Germany JS bite type fittings

avoid oil leak

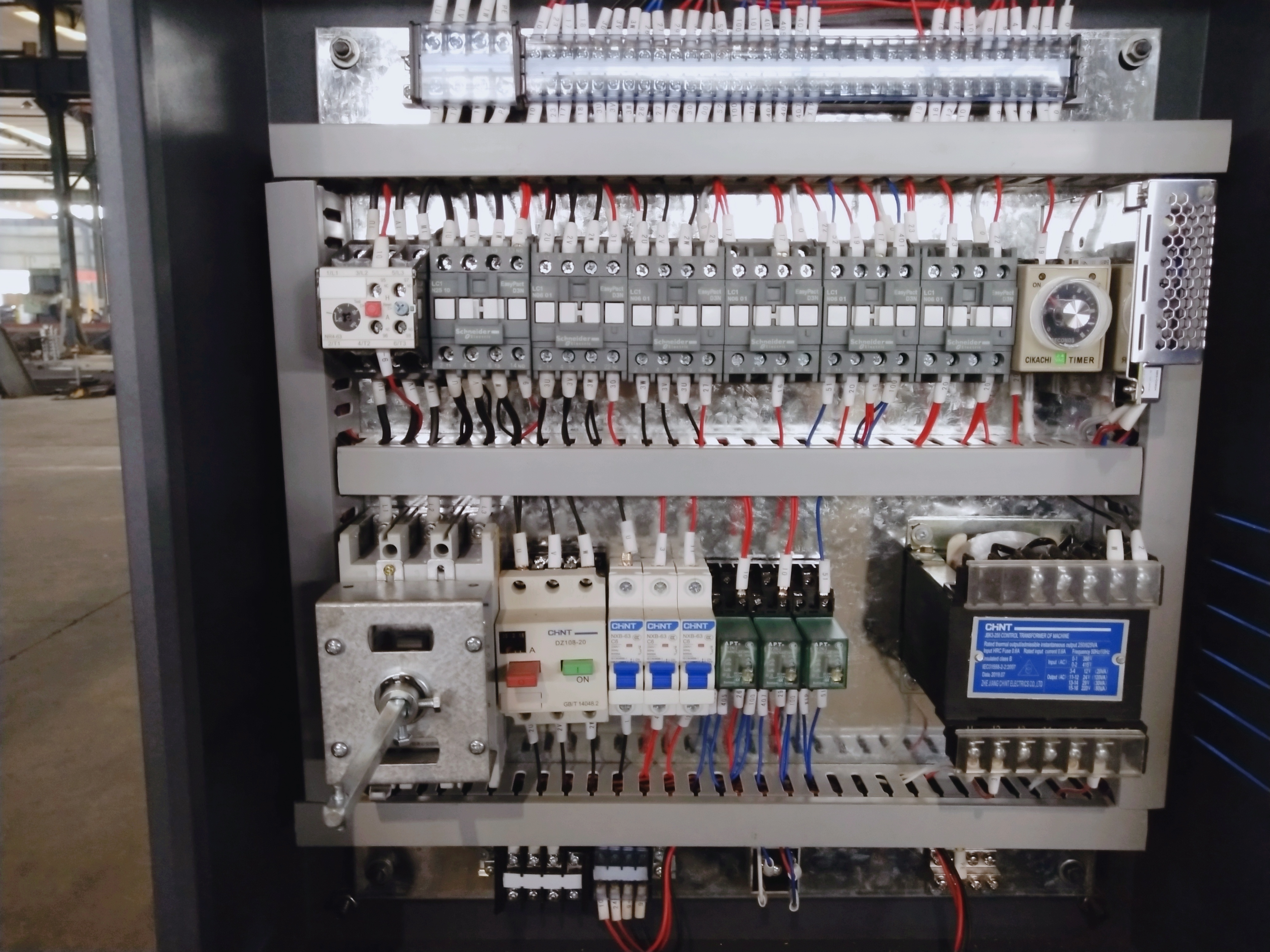

Electric cabinet

Siemens electric components

Cooling fan

oil cooling

Packing & Delivery

Hot Searches