- Product Details

- {{item.text}}

Quick Details

-

Power:

-

41

-

Dimension(L*W*H):

-

7000*1200*1800

-

Weight (KG):

-

4200

-

Application:

-

Crush Wood Logs

-

Usage:

-

Chip.shaving.sawdust

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUXI

-

Voltage:

-

308V

-

Power:

-

41

-

Dimension(L*W*H):

-

7000*1200*1800

-

Weight (KG):

-

4200

-

Application:

-

Crush Wood Logs

-

Usage:

-

Chip.shaving.sawdust

Product Description

Introduction

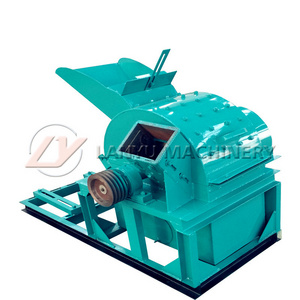

Saw dust powder making machine is widely used for chipping Wood logs into Wood Chips and powder as well. This chipper machine can chip soft and medium hard woods, green or seasoned, etc.

Process:Wood Logs are fed into the Sawdust Machine with the help of in feed belt conveyor through which the material gets into the contact with rotating sawdust machine blades. This process helps in converting the wood logs into sawdust in one go.

Electric Sawdust Making Machine

Diesel Sawdust Making Machine

|

Model

|

YX-210

|

YX-2150

|

YX-350

|

YX-3550

|

|||

|

Capacity

|

10m³/h

|

12m³/h

|

35m³/h

|

45m³/h

|

|||

|

Feed port size

|

210*210

|

210*500

|

350*350

|

500*350

|

|||

|

Roller shaft size

|

420*220

|

500*410

|

450*400

|

500*450

|

|||

|

Voltage

|

380v/50HZ

|

|

|

|

|||

|

Machine size

|

7000*1200*1800

|

7300*1400*2200

|

7000*1400*2200

|

8000*1600*2200

|

|||

|

Weight

|

3500

|

4000

|

5000

|

6000

|

|||

Final Product

As usual, the size of finished products is 24mm, the 110 mm also can be customized according to yourequest.

Raw Material

Our machine can deal with the size of the material from 5cm to 50cm, what's your max diameter?

According to your max size, we will suggest a suitable machine and a better price for you.

Application

♥Make bedding material for animals; chicken, horses, etc.

♥For wood charcoal

♥For wood particle

♥For Compost

More Pictures

Features

1. Introducing German technology, adopting European standards;

2. No need to install;

3. No need for civil works;

4. Except for cutters, no wearing parts;

5. No screen (dry and wet wood does not affect production)

6. Feeding diameter: 21 cm, 35 cm, 50 cm;

7. All kinds of large-scale wood, garden waste wood hardwood bark, furniture factory scraps and other corners can be crushed at one time (finished products are 2-5mm sawdust);

8. Long tool life (HSS tool can run continuously for 2400 hours, no need to replace, after the wear and tear, the blade can be taken out and polished to continue to use, reducing operating costs);

9. The price is cheaper, compared with the original German equipment 280,000 plus 41% import tax price, the existing price is more suitable for the Chinese market;

10. Before the equipment leaves the factory, it is installed and debugged. After arriving at the customer's site, it can be produced directly by electricity, efficient and rapid, saving time;

11. One person can operate, reducing labor intensity and cost.

Packaging & Shipping

Title goes here.

1. Packaging: 1)Wrapped by the protective film;

2)Packed by standard import & export wooden cases or carton boxes.

2. Shipping: By logistics; by automobile; by train; by shipping; by air etc.

Our Factory

1.2-3 engineers will be sent to help you installing the machine, debugging the machine, training your worker, until your machines working normally and your workforce operate skillfully.

2.2 year warranty for the spare parts and 20 years warranty for the heavy duty machine(without spare part) in normal working process.

3.Spare parts delivered at cost in short time to ensure your daily production.

4.Life-long maintaining and technical support.

5.Before leaving the factory, we will assemble all the equipment into production lines, simulate the actual use conditions for testing, to ensure the production line capacity and product quality. We sincerely invite customers to visit the operation of the equipment and receive relevant operation and maintenance training

Hot Searches