- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Zahndent

-

Model Number:

-

ZMD-5Z

-

Material:

-

metal

-

Model:

-

ZDM-5Z

-

Milling mode:

-

Dry

-

Milling material:

-

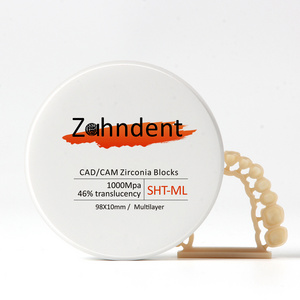

Zriconia,Pmma,Wax

-

Max spindle speed:

-

60000RPM/min

-

Spindle cooling:

-

Water cooling

-

Total capacity:

-

1800W

-

Voltage/current:

-

220V 50Hz

-

Loadable workpiece shape:

-

98 discs

-

Number of burs housed:

-

6

-

Positioning accuracy:

-

0.002mm

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support

-

Place of Origin:

-

China

-

Brand Name:

-

Zahndent

-

Model Number:

-

ZMD-5Z

-

Material:

-

metal

-

Model:

-

ZDM-5Z

-

Milling mode:

-

Dry

-

Milling material:

-

Zriconia,Pmma,Wax

-

Max spindle speed:

-

60000RPM/min

-

Spindle cooling:

-

Water cooling

-

Total capacity:

-

1800W

-

Voltage/current:

-

220V 50Hz

-

Loadable workpiece shape:

-

98 discs

-

Number of burs housed:

-

6

-

Positioning accuracy:

-

0.002mm

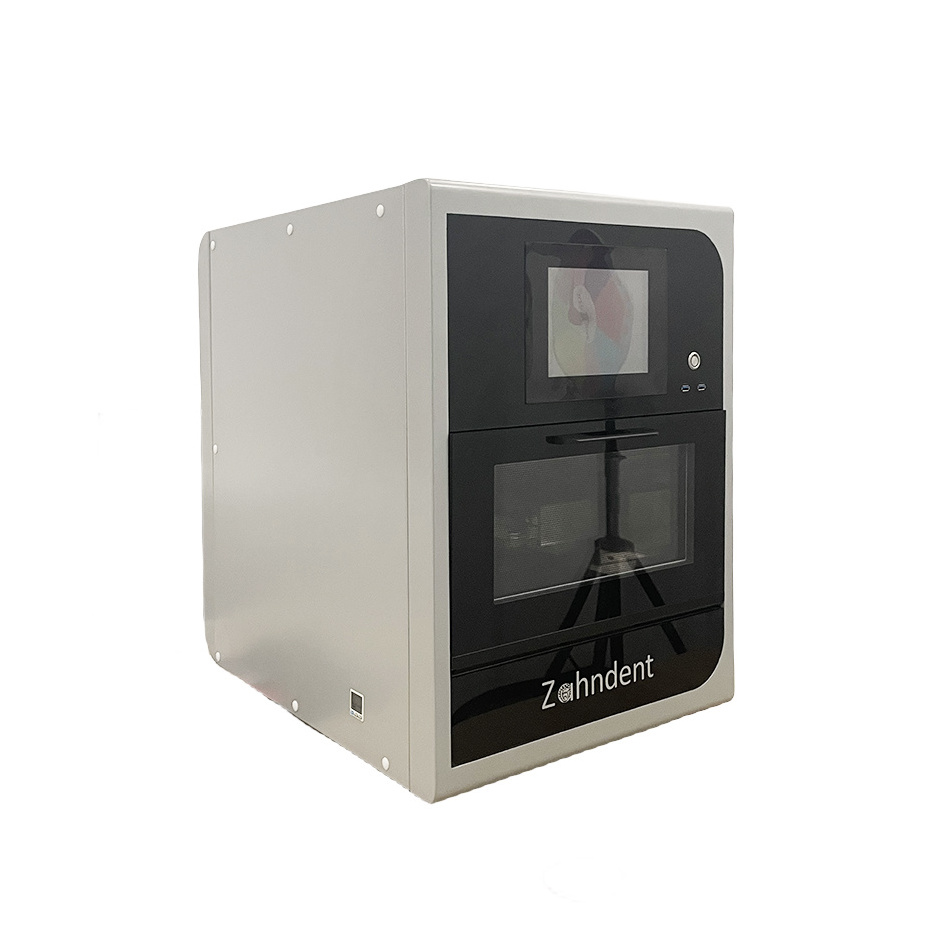

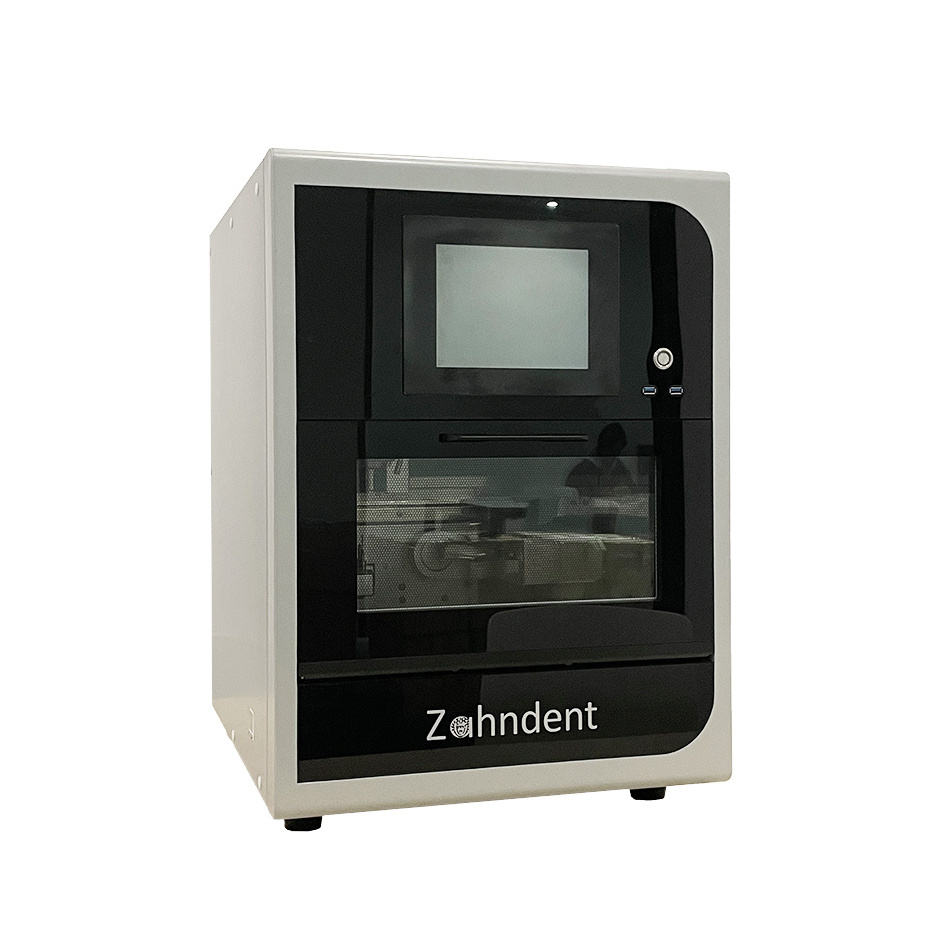

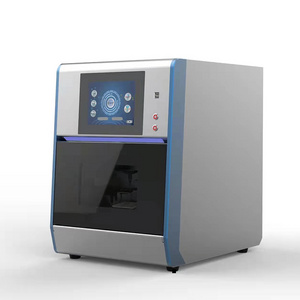

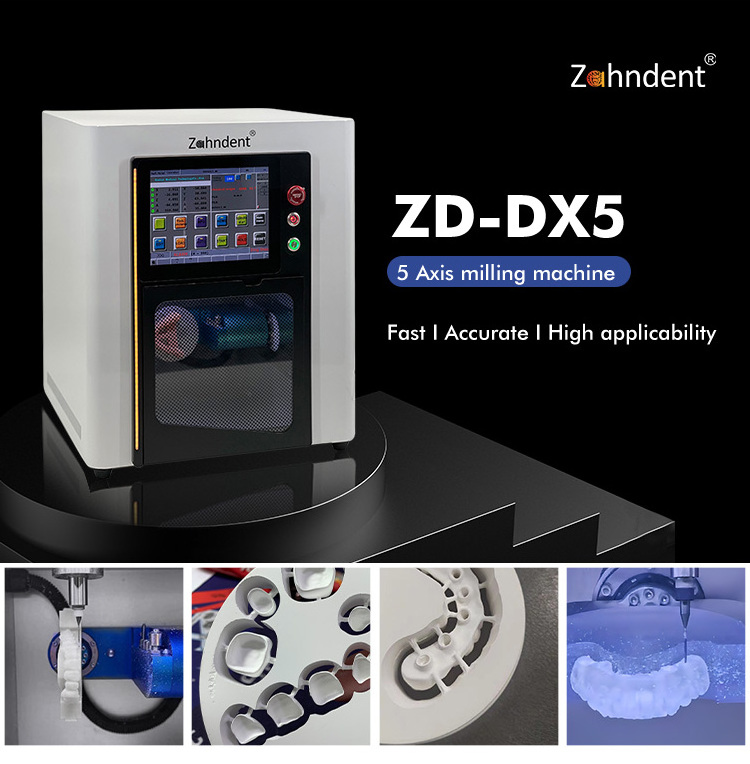

Five axis dental milling machine, CAD/CAM dental milling

Precision five axis milling of zirconia, wax, PMMA, etc.

Digital dental technology has brought significant benefits to laboratories, dentists, technicians, and patients. As a provider of digital dental solutions, we can easily produce high-quality, astonishingly accurate, and cost-effective dental restorations.Whether you are just entering digital dentistry and CAD/CAM dental milling machines, or expanding your current restoration production.

Precision five axis milling of zirconia, wax, PMMA, etc.

Digital dental technology has brought significant benefits to laboratories, dentists, technicians, and patients. As a provider of digital dental solutions, we can easily produce high-quality, astonishingly accurate, and cost-effective dental restorations.Whether you are just entering digital dentistry and CAD/CAM dental milling machines, or expanding your current restoration production.

|

Model

|

ZD-DX5

|

|

Axis

|

5

|

|

Milling mode

|

Dry

|

|

Millable material

|

Zirconia,Wax,PMMA,Peek

|

|

Product type

|

Crown/Coping,Bridge,Inlay/Onlay

|

|

Average milling time(Dental crown)

|

Zirconia 8-15min,Wax 5min,PMMA 8-15min

|

|

Max spindle speed

|

60000 RPM/min

|

|

Range of rotation & tling rotation

|

A-Axis:-30°to+120°

|

|

Total capacity

|

1000W

|

|

Spindle cooling

|

Air cooling

|

|

C-Axis

|

360°

|

|

Voltage/current

|

220V 50/60Hz

|

|

Repeatability

|

0.005mm

|

|

Remote maintenance

|

remote A/S

|

|

Number of burs(Tools)housed

|

4

|

|

Compressed air

|

7bar50L/min

|

|

The size of material

|

98*10mm to 98*25mm

|

|

Controller

|

Delta

|

|

External dimension

|

460*420*500mm

|

|

Packing dimension

|

660*660*750mm

|

|

N.W/G.W

|

65KG/80KG

|

|

Package

|

Plywooden case

|

|

CAM software

|

Worknc

|

|

Language

|

English/French/German/Spanish/Japanese/Chinese

|

FAQ

Q: Are you a manufacturer, or a trading company?

A: We are an OEM/ODM manufacturing company.

Q: What's the delivery time?

A: 5 -7 working days by express. International express company have DHL ,TNT, FedEx, Aramex, SF express.......

Our forwarder has the ability to deliver the goods to your door, our service attitude, we serve 24 hours at any time, you have any needs can tell us, as long as the reasonable range, can meet you

Q: Do you provide samples ?

A: Yes, we would like to provide samples for free but customers will bear the shipping cost .

Q: Can I print our own logo or design on the products ?

A: We accept OEM or ODM, we can print your own logo according to your requirements.

Q: How can we guarantee quality?

A: We strictly follow the ISO quality system. In addition, from the raw material side, we will conduct performance test on

theZirconia powder. We even have a dental lab to conduct a strict quality inspection process from the Zirconia powder to the final finished tooth, so as to confirm that the goods received by the buyer are stable and good.

Q: Are there differences among zirconia ceramics ?

A: Difference among zirconia ceramic can occur with the level of purity of zirconia, grain size, trace elements and stabilizing compounds, and consistency of formulation.Difference can exist in shrinkage from batch to batch because of differences in the thermal expansion(CTE).

Hot Searches