Wooden Cases Packing for Boiler Auxiliaries

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

25-40 ton

-

Steam Capacity:

-

2-25 t/h

-

Working Pressure:

-

1.0-2.5 MPa

-

Steam Temperature:

-

184-224 ℃

-

Feed Water Temp.:

-

20-105 ℃

-

Design fuel:

-

Coal

-

Thermal efficiency:

-

≥82%

-

Operation:

-

Automatic feeding fuel

-

Power Supply:

-

220V/380V/415V, 50HZ/60HZ(Arbitrary)

-

Color:

-

Customization

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yuji Boiler

-

Dimension(L*W*H):

-

Depends on Model

-

Weight:

-

25-40 ton

-

Steam Capacity:

-

2-25 t/h

-

Working Pressure:

-

1.0-2.5 MPa

-

Steam Temperature:

-

184-224 ℃

-

Feed Water Temp.:

-

20-105 ℃

-

Design fuel:

-

Coal

-

Thermal efficiency:

-

≥82%

-

Operation:

-

Automatic feeding fuel

-

Power Supply:

-

220V/380V/415V, 50HZ/60HZ(Arbitrary)

-

Color:

-

Customization

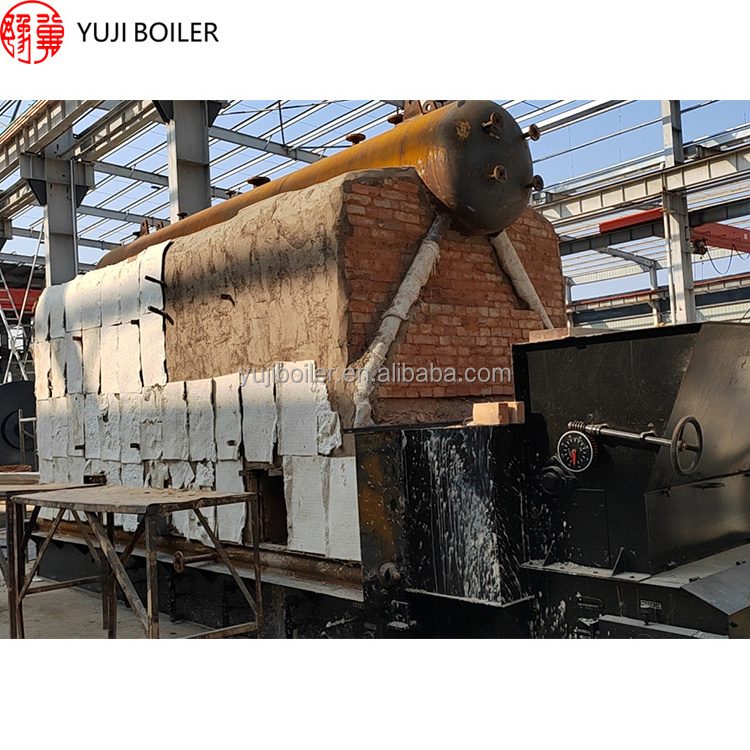

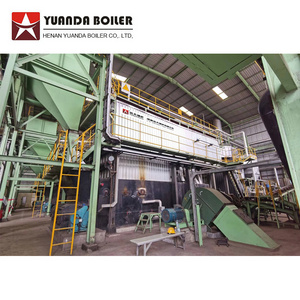

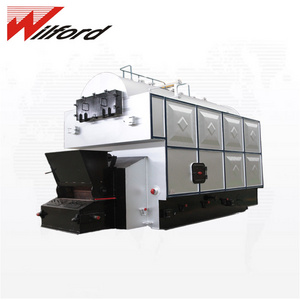

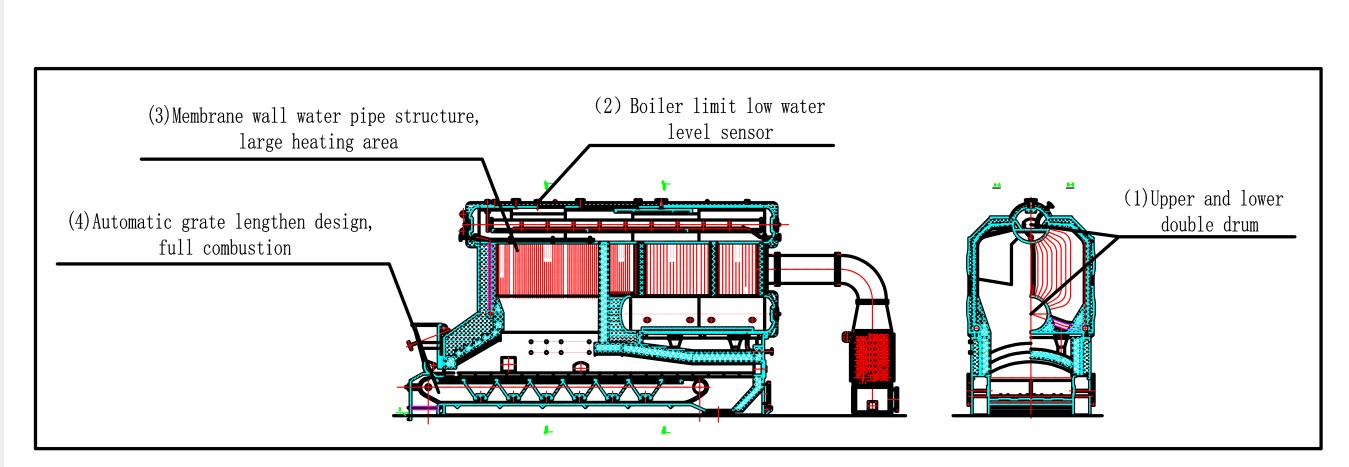

SZL Series Double Drum Chain Grate Coal Fired Steam Boiler

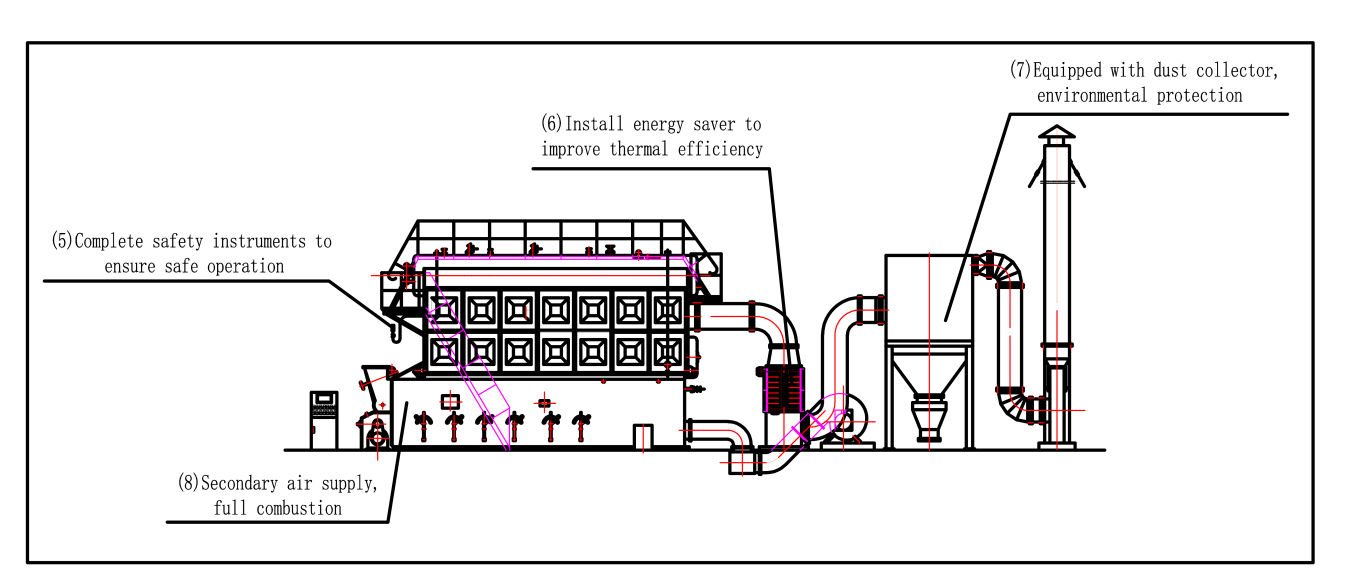

SZL series boiler host design as double boiler drum longitudinal layout, set steam water separating device in upper boiler drum, set periodic blow-off device in lower boiler drum, there are water cooling wall tubes at left and right side of furnace. Use light chain grate add coal fuels automatically, the back of furnace is re-burning chamber, convection tubes, the tail of furnace is economizer or air preheater, equip with blower, draft fan for mechanical ventilation, and also equip with slag extractor for slagging automatically. Fuel fall down to chain grate and enter furnace for burning, the flue gas go through furnace, re-burning chamber, convection tubes, economizer or air preheater into tail flue, enter deduster, draft fan and chimney, and finally discharge into atmosphere.

1. Advanced Arch Design

1.1 Furnace arch adopt advanced design, forming obvious inverse "α" flue gas flow, which makes the boiler strong adaptability of different fuels.

1.2 The front and back arches are "wet arch" structure, keep a constant temperature and protect the arch.

2. Membrane Water Wall

2.1 Adopt water cooling combustion chamber, increase the radiant heating area, improve the output and thermal efficiency.

2.2 The boiler body use membrane water wall structure, good sealing, low heat lose.

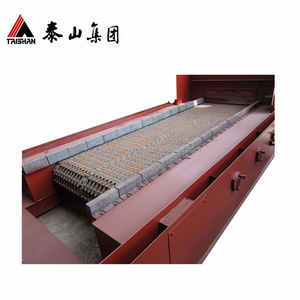

3. Excellent Chain Grate

3.1 The grate is 500~1000 mm longer than others, the fuel combustion time is longer, improve the combustion efficiency.

3.2 The small scale flake grate could resist the temperature as high as 1200℃, long working life.

3.3 The chain grate are low coal leakage because of the small gap.

3.4 High automatic degree, decrease labor cost.

3.5 Convenient for maintenance, it could be done without boiler shut down.

4.Anti Coking Measures

4.1 The left and right headers are designed as anti-coking headers.

4.2 Adopt unique double secondary air design, improve the ignition condition of coal fuels, sufficient air supply to make sure the high combustion efficiency, and avoid fuel coking.

5. Sufficient Output

Equip with double drums, membrane water wall, and large diameter furnace, the radiant heating area increase more than 50%, achieve sufficient output.

6. Low Thermal Inertia Insulating Layer

Boiler shell use light aluminum silicate board for heat preservation, low thermal inertia, and low heat loss. The temperature of furnace rise up quickly.

7. Both Sides Air Inlets

Boiler adopt bilateral air inlets and independent wind chambers, could adjust wind volume and pressure flexible, to ensure the sufficient combustion.

Coal

Apply for various type of coal fuels.

Automatic Chain Grate Stoker

Automatic feeding fuels, suitable for kinds of coal fuels, save labor and full combustion, save fuels.

Arched tube plate

reduce the stress of welding

Spirally Corrugated Tube

high transfer efficiency

PLC Automatic Control Cabinet

users could designate the brand of electric elements

Refractory Bricks

high temperature refractory bricks, no air leakage

Insulation Layer

insulation layer use Aluminum silicate board, low heat loss

Economizer

made of ND corrosion resistant steel, save fuel, improve thermal efficiency.

|

Item

|

Unit

|

SZL2

|

SZL4

|

SZL6

|

SZL8

|

SZL10

|

SZL15

|

SZL20

|

SZL25

|

|||||||

|

Steam Capacity

|

t/h

|

2

|

4

|

6

|

8

|

10

|

15

|

20

|

25

|

|||||||

|

Working Pressure

|

MPa

|

1.0/1.25/1.6/2.5

|

|

|

|

|

|

|

|

|||||||

|

Steam Temp.

|

℃

|

184/193/204/224

|

|

|

|

|

|

|

|

|||||||

|

Feed Water Temp.

|

℃

|

20-105

|

|

|

|

|

|

|

|

|||||||

|

Thermal Efficiency

|

%

|

≥82

|

|

|

|

|

|

|

|

|||||||

|

Fuel Consumption

|

kg/h

|

313.2

|

619.8

|

843.4

|

1242.1

|

1550.4

|

2343.7

|

3095

|

3879

|

|||||||

|

Heating Area

|

m

2

|

81.26

|

165.26

|

239

|

358.8

|

391

|

564

|

843

|

1130

|

|||||||

|

Grate Area

|

m

2

|

2.8

|

6.04

|

8.64

|

11.71

|

13.64

|

15.33

|

19.16

|

26.3

|

|||||||

|

Total Power

|

KW

|

25.3

|

36

|

64

|

76.2

|

97.7

|

138

|

206.5

|

218

|

|||||||

|

Water Capacity

|

m

3

|

2.64

|

4.9

|

6.33

|

6.67

|

10.6

|

12.1

|

13.6

|

16

|

|||||||

|

Transport

Dimension

|

L(mm)

|

5600

|

7380

|

6900

|

7000

|

8200

|

8700

|

11900

|

10700

|

|||||||

|

|

W(mm)

|

2500

|

2700

|

2660

|

3400

|

3000

|

3300

|

3200

|

3000

|

|||||||

|

|

H(mm)

|

3500

|

3740

|

3500

|

3700

|

3500

|

3570

|

2360

|

4000

|

|||||||

|

Transport Weight

|

t

|

24.5

|

31

|

30

|

32.5

|

34

|

35

|

35

|

36

|

|||||||

Water proof and damp proof package for Boiler Host

A: Yes, we are professional manufacturer of boiler and pressure vessels in Henan, China.

Q: Do you have any Certificate?

A: Yes. Our boiler have got China GB ISO certificates and CE certificate of EU. We also can provide ASME, GHOST and other necessary certificates if you need.

Q: How can I pay you?

A: T/T, Western Union, Money Gram and Ali Trade Assurance is better.

Q: What about the delivery time?

A: 5-10 working days for single machine, and 30-40 working days for bulk order and door to door delivery service is also available.

Q. What about the warranty?

A: We provide 1 year warranty for free and life-long time maintenance

Q. What about installation?

A: We provide 1 or 2 technicians overseas services for installation, debugging and training.