- Product Details

- {{item.text}}

Quick Details

-

Spangle Type:

-

Zero Spangle

-

Hardness:

-

Mid Hard

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

delong steel

-

Length:

-

Customized

-

Grade:

-

DX51D

-

Delivery Time:

-

7-14 days

-

MOQ:

-

5 Tons

-

Zinc Coating:

-

Z30-Z275g/㎡

-

Surface Treatment:

-

Passivation or Chromated, Skin Pass,Oil or Unoiled,or Antifinger print

-

Surface Structure:

-

Small/ Regular/ Big/ Non-Spangle

-

Package:

-

Sea-worthy Package

-

Payment:

-

30%TT+70%TT / LC

-

Product Name:

-

Galvanized Steel Sheet

-

Packing:

-

Seaworthy Package

Quick Details

-

Type:

-

Steel Coil

-

Thickness:

-

0.12mm-3mm;11 gauge-36gauge, 0.12mm-3mm;11 gauge-36gauge

-

Coating:

-

Z181-Z275

-

Spangle Type:

-

Zero Spangle

-

Hardness:

-

Mid Hard

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

delong steel

-

Length:

-

Customized

-

Grade:

-

DX51D

-

Delivery Time:

-

7-14 days

-

MOQ:

-

5 Tons

-

Zinc Coating:

-

Z30-Z275g/㎡

-

Surface Treatment:

-

Passivation or Chromated, Skin Pass,Oil or Unoiled,or Antifinger print

-

Surface Structure:

-

Small/ Regular/ Big/ Non-Spangle

-

Package:

-

Sea-worthy Package

-

Payment:

-

30%TT+70%TT / LC

-

Product Name:

-

Galvanized Steel Sheet

-

Packing:

-

Seaworthy Package

Product Description

|

Product name

|

Galvanized steel Plate/sheet

|

|

Material

|

DX51D,SGCC,G300,G550,SPCC,SPCD,SPCE,ST12-15,DC01-06,Q195A-Q235A,Q195AF Q235AF,Q295A(B)-Q345A(B)

|

|

Surface Treatment

|

Passivation or Chromated, Skin Pass,Oil or Unoiled,or Antifinger print

|

|

Spangle Types

|

Free Spangle(No Spangle),Minimal Spangle,Regular Spangle

|

|

Zinc coating

|

Z40~Z275

|

|

Thickness

|

0.12-6.00mm

|

|

Width

|

600mm to 1500mm

|

|

Length

|

According to customer's requirement or cut into sheet

|

|

Coil Weight

|

3~10Tons

|

|

Inner Diameter

|

508mm / 610mm

|

|

Tensile strength

|

200-550 n/mm2

|

|

Elongation

|

16~30%

|

|

Standard

|

GB,JIS,DIN,AISI,ASTM

|

|

MOQ

|

1 ton

|

|

Surface

|

Clean, blasting and painting according to customer requirement

|

|

Delivery Detail

|

About 5-7 days after receive the deposit.

|

|

Shipment time

|

Within 15-20 workdays after receiving deposit or L/C

|

|

Export packing

|

Waterproof paper, and steel strip packed.Standard Export Seaworthy Package.Suit for all kinds of transport,or as required

|

|

Machining

|

Custom, Kaiping, cutting, pattern

|

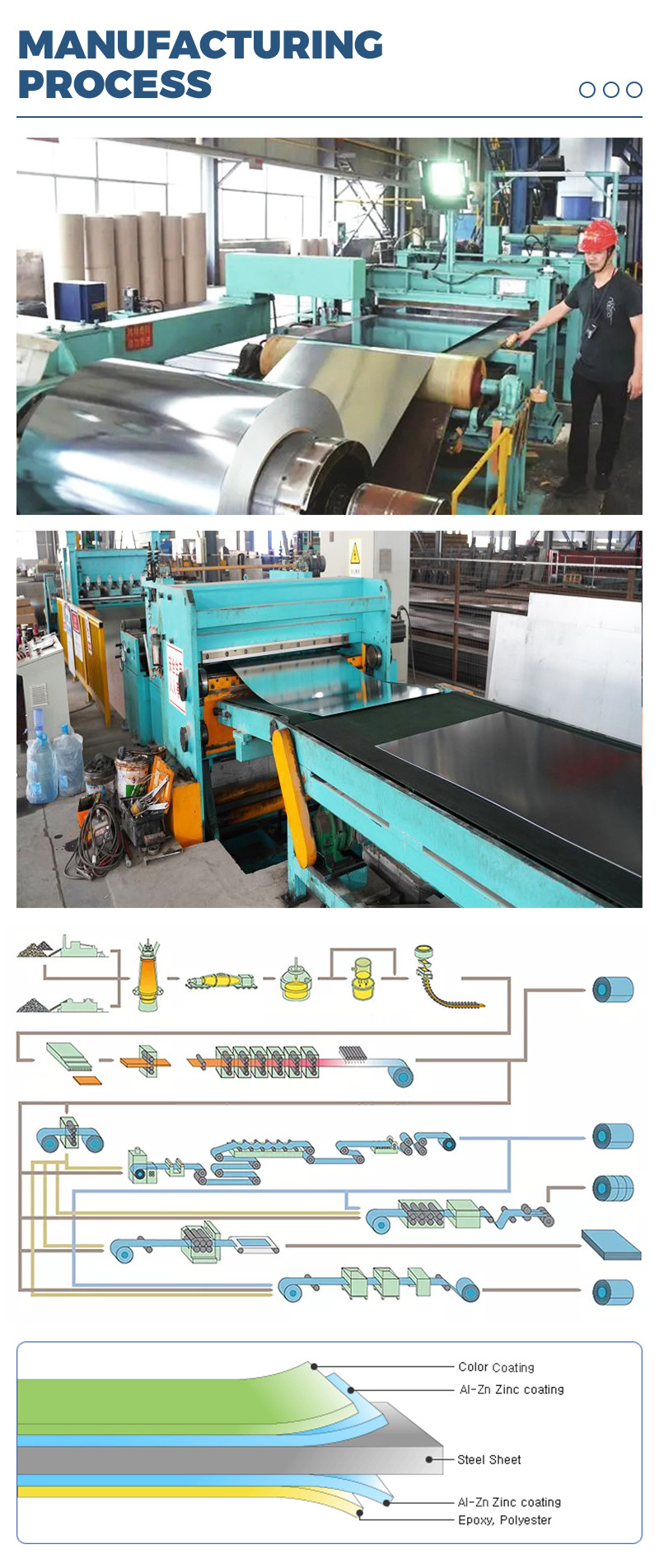

Manufacturing Process

1. Pre-Treatment Process

Some rolling oil and other contaminants remain on the surface of cold rolled steel sheets following processing. These are removed by passing the electrically charged sheet through an alkaline solution which induces an electrochemical reaction.

2. Annealing

The material properties of the pre-treated steel sheet can be altered and improved through recrystallization during the annealing process.

3. Hot-Dip Galvanizing

After passing through the annealing furnace, steel sheets are dipped into a zinc pot where molten Zn is coated onto the surface. The desired coating weight is achieved by removing excess zinc before solidification with high-pressure air from an air knife.

4. Galvannealing

The surface of a steel sheet, after the air knife, can be coated with a zinc compound prior to reheating in an annealing process. Zn atoms diffuse into the Fe to create a Zn-Fe series alloy.

5. SPM & Chemical Treatment

In order to achieve a flat surface and an elegant finish, the steel sheet is processed with a skin pass mill. In order to prevent the white rust, which often forms on the surface of activated zinc, and to improve corrosion resistance, the surface is coated with a Cr-free resin.

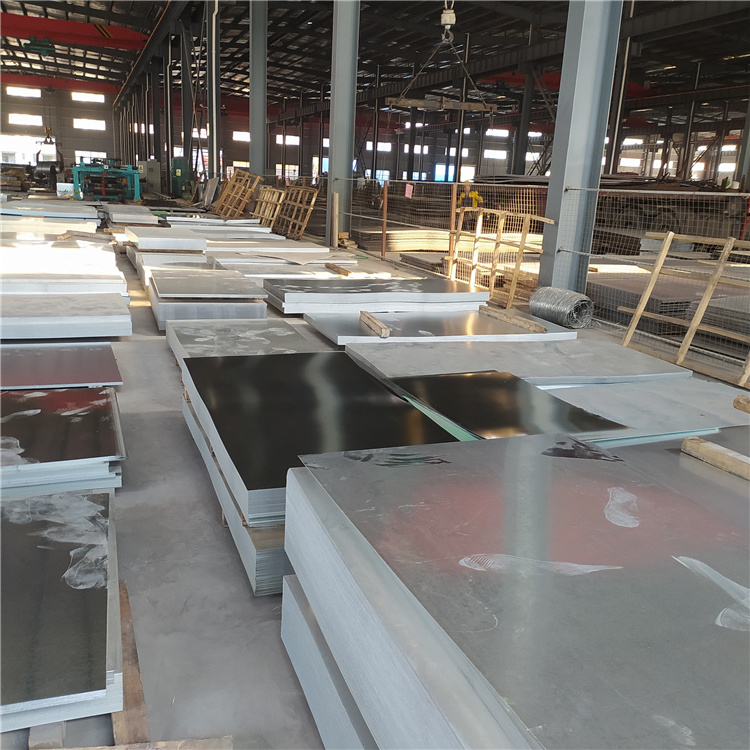

6. Inspection & Sliting

Located at the line’s exit section are a side trimmer, inspection table, oil coating machine and coiling equipment. At this station, all products are inspected and judged relative to material specifications required by the customer. The steel sheet is the product after the steel coil is cut.

Advantages

why choose galvanized steel sheet?

1.Outlook Beautiful and novel,rich colors,flexible combination,can be used in different building to express special original architectural styles in life

2.Surface have been treated as galvanized and color coated.so it can anti-rain,anti-fire,anti-quake,So it has a long term life as 20-30 year and color just not fade

3.Light weight:easy to transport the material,short the time to finish the building,reduce worker's hard work,save much time and energy for human beings

4.Smooth surface treatment,the dust will be easy taken off by the rain

5.Environmental material,can be used many times,will do no hard to the our environment.

6.1000 width,and 880 effective width or as your requirement,for easy set up.

7.Prime anti-fire application,which is confirmed by GB50222-95 as difficult to fire as B

8.Impact resistance,strength is 250-300 times of common glass,2-20times of tempered glass,

9.Energy saving:keep summer cool,winter warm.Heat insulation effect is higher 7%-25%than that of the common glass,then heat loss is greatly reduced.

10.insulation resistance:corrugated sheet with obvious effect of noisy.

11.Light in weight,and have very good beatification vision effect.

Applications

Packing & Delivery

Feedback

Certificates & Exhibitions

FAQ

Hot Searches