- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Vacuum homogenizing emulsifying mixer

-

Stirring Mixing Way:

-

One-way Frame

-

Heating Method:

-

Electric/Steam Heating

-

Homogening speed:

-

0-3000 RPM

-

Mixing speed:

-

0-63 R/min

-

Structure:

-

Double Jacket

-

Control:

-

PLC+ Touch Screen/ Button control

-

Advantage:

-

High Efficieccy

-

MOQ:

-

1 Set

-

Discharging Ways:

-

Positive pressure discharging

Quick Details

-

Brand Name:

-

DuanYue

-

Type:

-

Homogenizer

-

Weight (KG):

-

680

-

Product name:

-

Vacuum homogenizing emulsifying mixer

-

Stirring Mixing Way:

-

One-way Frame

-

Heating Method:

-

Electric/Steam Heating

-

Homogening speed:

-

0-3000 RPM

-

Mixing speed:

-

0-63 R/min

-

Structure:

-

Double Jacket

-

Control:

-

PLC+ Touch Screen/ Button control

-

Advantage:

-

High Efficieccy

-

MOQ:

-

1 Set

-

Discharging Ways:

-

Positive pressure discharging

Products Description

Scrub Cream Making Machine Vacuum Emulsifying Mixer for Cosmetic Vacuum Homogenizing

Product Feature

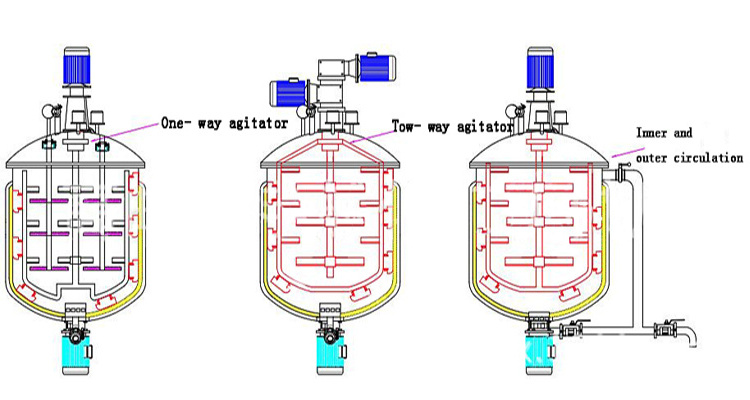

1) Three mixing pot: oil and water mixing pot; main mixing pot.

2) Main pot --Mixer 0-63 rpm scraper mixer: on the lid

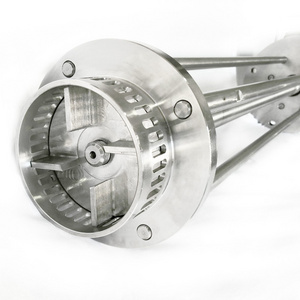

3) Main pot--Homogenizer: 0-3000rpm variable: at the bottom of the pot

4) Main pot is in vacuum state during the working to avoid bubbles

5) Water&oil pot are working under atmospherical pressure, turbine stir

6) Lid of the main pot is lifted by PLC controlled hydraulic cylinder

7) Material feeding of main pot: vacuum suction

8) With electric control case, PLC controlled

9) SIEMENS motors, all components are international brands

10) Generally the parts have contact with material adopt SUS316L, other parts SUS 304.

2) Main pot --Mixer 0-63 rpm scraper mixer: on the lid

3) Main pot--Homogenizer: 0-3000rpm variable: at the bottom of the pot

4) Main pot is in vacuum state during the working to avoid bubbles

5) Water&oil pot are working under atmospherical pressure, turbine stir

6) Lid of the main pot is lifted by PLC controlled hydraulic cylinder

7) Material feeding of main pot: vacuum suction

8) With electric control case, PLC controlled

9) SIEMENS motors, all components are international brands

10) Generally the parts have contact with material adopt SUS316L, other parts SUS 304.

Detailed Images

Product Paramenters

|

Model

|

Capacity

|

Mixing Power

|

Mixing Speed

|

Homongenizing Power

|

Homongenizing Speed

|

Heatting method

|

|

PME-200

|

200

|

0.75

|

0-65

|

2.2-4

|

3000

|

Steam Heating or Electric Heating(optional)

|

|

PME-300

|

300

|

0.75

|

0-65

|

2.2-4

|

3000

|

|

|

PME-500

|

500

|

2.2

|

0-65

|

5.5-7.5

|

3000

|

|

|

PME-1000

|

1000

|

4

|

0-65

|

7.5-11

|

3000

|

|

|

PME-2000

|

2000

|

5.5

|

0-53

|

11-15

|

3000

|

|

|

PME-3000

|

3000

|

7.5

|

0-53

|

18

|

3000

|

|

|

PME-5000

|

5000

|

11

|

0-42

|

22

|

3000

|

|

|

PME-10000

|

10000

|

15

|

0-42

|

30

|

3000

|

|

Suitable For

Hot Searches