- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

28064-14-4

-

Place of Origin:

-

Taiwan, China

-

Brand Name:

-

FONG YONG

-

Model Number:

-

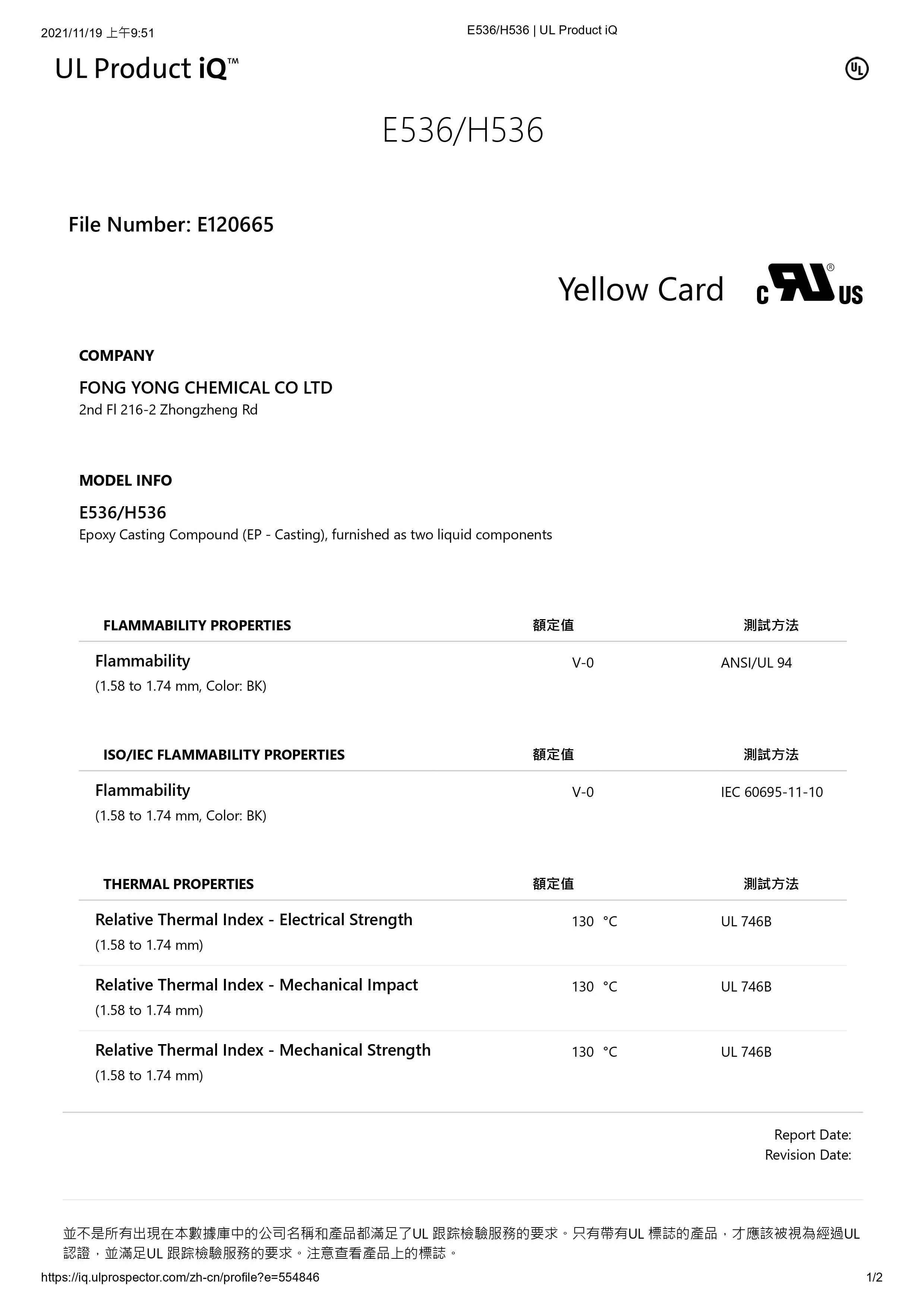

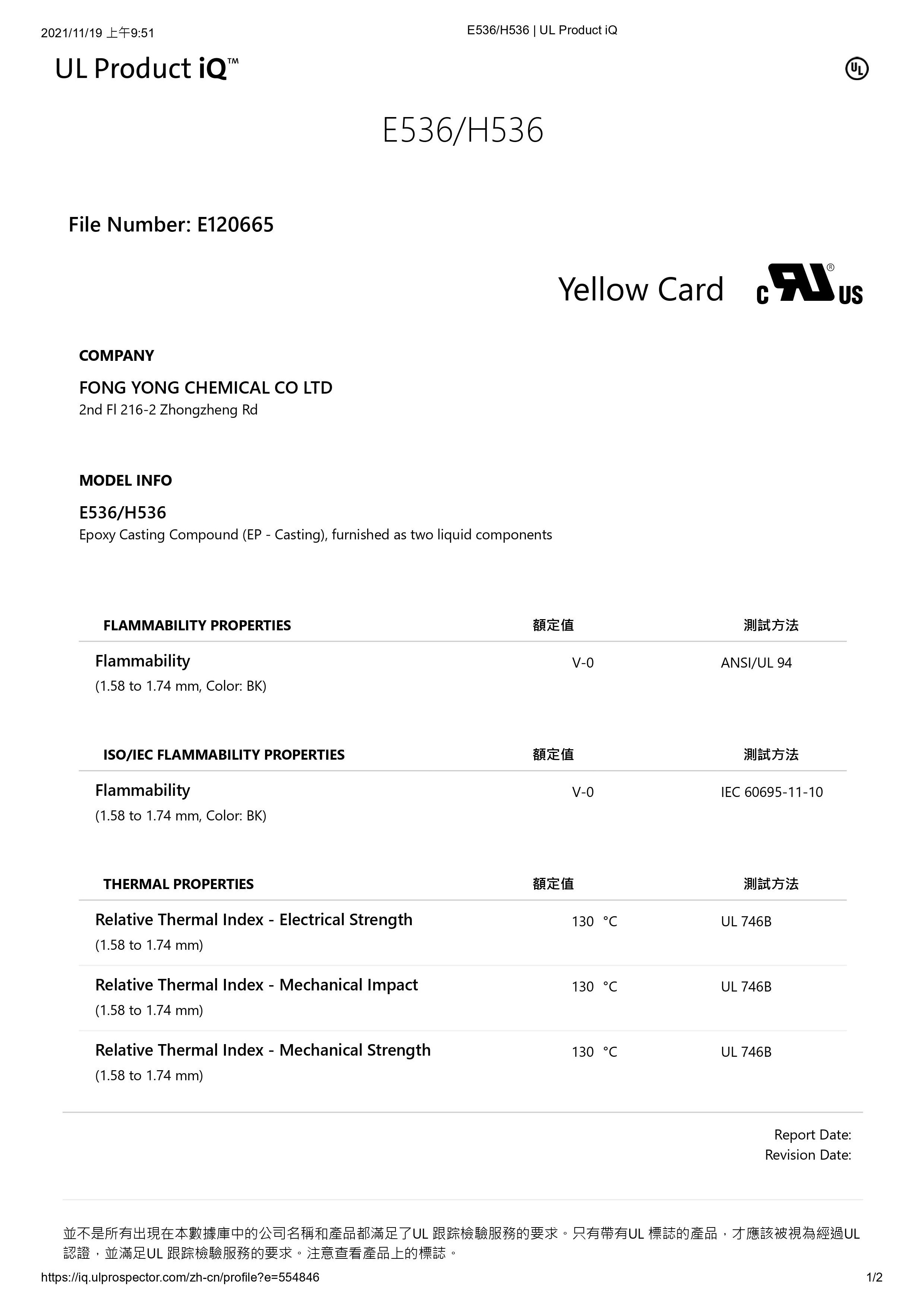

E536/H536

-

Type:

-

Two components black AB glue

-

Color:

-

Black

-

Mixing ratio:

-

100:30

-

Flammable retardant:

-

UL-94v0

-

Appearance:

-

Black liquid

-

Product name:

-

E536/H536

-

Application:

-

Potting against water, temperature, chemical...

-

Name:

-

epoxy resin

-

Keywords:

-

casting resin

-

Certificate:

-

RoHS, REACH, IATF-16949fd, fire resistance

Quick Details

-

CAS No.:

-

28064-14-4

-

Other Names:

-

Electronic potting compound

-

MF:

-

mixture

-

EINECS No.:

-

28064-14-4

-

Place of Origin:

-

Taiwan, China

-

Brand Name:

-

FONG YONG

-

Model Number:

-

E536/H536

-

Type:

-

Two components black AB glue

-

Color:

-

Black

-

Mixing ratio:

-

100:30

-

Flammable retardant:

-

UL-94v0

-

Appearance:

-

Black liquid

-

Product name:

-

E536/H536

-

Application:

-

Potting against water, temperature, chemical...

-

Name:

-

epoxy resin

-

Keywords:

-

casting resin

-

Certificate:

-

RoHS, REACH, IATF-16949fd, fire resistance

Black Electrical Resin Epoxy for Protecting Electrical Components

Fong Yong electronic component potting material E536/H536 is a kind of ab glue, hard type epoxy resin and hardener complying with

fire rating UL-94v0. This circuit board epoxy potting compound is designed for high temperature resistance potting, sealing and

encapsulation of electronic parts. This circuit board encapsulant has good water resistance, chemical resistance, thermal shock resistance and excellent electrical insulation properties and excellent bond strength. This epoxy on pcb can be cured at high temperature in the oven to meet the requirements of high temperature resistance. The thermally conductive potting compound E532/H532 is the best solution for potting and encapsulation of electronic/electrical components requiring flame retardant UL-94v0 certification and thermal conductivity.

Products Description

|

Country of origin:

|

Taiwan

|

|

Part No.:

|

E536/H536

|

|

MOQ

|

1kg

|

|

Usages

|

water resistance/chemical resistance/ heat resistance/fire resistance

|

|

Product properties:

|

|

|

|

|

||||

|

Part No

|

E536

|

|

H536

|

|

||||

|

Appearance

|

Black liquid

|

|

Amber liquid

|

|

||||

|

Viscosity (cps, 25 ℃)

|

150,000 ~ 240,000

|

|

50 ~ 160

|

|

||||

|

Mixed viscosity

(cps, 25 ℃)

|

1,500 ~ 1,800

|

|

|

|

||||

|

Pot life (25 ℃)

|

24 hours

|

|

|

|

||||

|

Curing conditions

|

80 ℃ x 2 hours + 120 ℃ x 4 hours

|

|

|

|

||||

|

Hardness (shore D)

|

87

|

|

|

|

||||

|

Thermal Conductivity (W/m‧K)

|

0.5

|

|

|

|

||||

|

Heat dissipation temperature ( ℃)

|

118

|

|

|

|

||||

|

Frame Resistivity Level

|

UL 94V0 Approval (UL file No. E120665)

|

|

|

|

||||

Product Category

When did we start?

1983.

What are we “MANUFACTURING”?

1. One component and two component epoxy resin and hardener for potting, encapsulating and coating on electronic components for the requirements of fire resistance, electrical insulation, water resistance, thermal conductivity, weather resistance, chemical resistance…etc.

2. AB epoxy glue for doming, casting, coating on label stickers, artworks, graphics, woodworking like river tables,

1983.

What are we “MANUFACTURING”?

1. One component and two component epoxy resin and hardener for potting, encapsulating and coating on electronic components for the requirements of fire resistance, electrical insulation, water resistance, thermal conductivity, weather resistance, chemical resistance…etc.

2. AB epoxy glue for doming, casting, coating on label stickers, artworks, graphics, woodworking like river tables,

bar top coating, dining tables…

3. Flexible polyurethane urethane pu resin and hardener for motorcycle tank decals, automotive identification decals.

4. One part and two component rtv cure liquid silicone rubber sealant for sealing, bonding and potting on electronic components for requirement of high temperature resistance.

5. UV light curing glue for universal bonding, sealing and coating.

6. rtv 1 silicone conformal coating.

7. Structural adhesive for universal bonding.

8. Floor coating epoxy.

9. Others…

3. Flexible polyurethane urethane pu resin and hardener for motorcycle tank decals, automotive identification decals.

4. One part and two component rtv cure liquid silicone rubber sealant for sealing, bonding and potting on electronic components for requirement of high temperature resistance.

5. UV light curing glue for universal bonding, sealing and coating.

6. rtv 1 silicone conformal coating.

7. Structural adhesive for universal bonding.

8. Floor coating epoxy.

9. Others…

Where are our main markets?

Asia, Middle East, Euro areas, American, Australia, New Zealand.

How start our cooperation?

1. Provide us details of your applications and requirements.

2. Solve problems and confirm the products.

3. Quote-pay-delivery.

4. After sale service.

5. Re-order regularly.

Why us?

1. More than 30 years experiences of resin formulation, manufacturing and distributing.

2. Instant technical support.

3. Strict SOP for manufacturing, QC test and fast order delivery.

4. Small orders are accepted.

5. Customs made products for unique requirements.

6. OEM/ODM order available.

7. Multi-payment methods: Bank wire transfer, Western Union, Paypal, Alibaba payment.

How to contact with us?

Email: fong.yong01@msa.hinet.net;fongyong@fongyong.com.tw;fongyong@ms23.hinet.net

Skype: chialinglee5612

Wechat/whatsapp: +886983197925

Tel: +886226824939 ext 211

Where are we?

New Taipei City, Taiwan

Asia, Middle East, Euro areas, American, Australia, New Zealand.

How start our cooperation?

1. Provide us details of your applications and requirements.

2. Solve problems and confirm the products.

3. Quote-pay-delivery.

4. After sale service.

5. Re-order regularly.

Why us?

1. More than 30 years experiences of resin formulation, manufacturing and distributing.

2. Instant technical support.

3. Strict SOP for manufacturing, QC test and fast order delivery.

4. Small orders are accepted.

5. Customs made products for unique requirements.

6. OEM/ODM order available.

7. Multi-payment methods: Bank wire transfer, Western Union, Paypal, Alibaba payment.

How to contact with us?

Email: fong.yong01@msa.hinet.net;fongyong@fongyong.com.tw;fongyong@ms23.hinet.net

Skype: chialinglee5612

Wechat/whatsapp: +886983197925

Tel: +886226824939 ext 211

Where are we?

New Taipei City, Taiwan

Certifications

Q1: Why is my resin wavy?

A1: Sometimes, resin components can crystallize when the kit has gotten too cold. These crystals can show up as swirls or waves in resin. Before using the kit again, gently warm it in a warm water bath. Moisture has contaminated the resin.

Q2: What is thermal paste?

A2: Thermal paste or thermal interface material (TIM) is an agent or material that transfers heat. It is used to fill gaps between two metals.

Q3: What is an RTV Silicone?

A3: An RTV (Room Temperature Vulcanization) silicone sealant is a sealant that begins to cure immediately upon being exposed to air (specifically the moisture present in the air), as opposed to water based sealants such latex.

Q4: Is silicone lubricant the same as silicone grease?

A4: Silicone grease Silicone grease and paste are frequently meant the same thing. They are used for lubrication and because they wrap the area of application they protect the parts from rust and elements.

Q5: Is silicone gel a polymer?

A5: "Silicone gels" are optimized polymeric resins used for such applications, especially for protecting surfaces of organic integrated circuit chips due to their ability to replace conventional ceramic hermetic packaging.

A1: Sometimes, resin components can crystallize when the kit has gotten too cold. These crystals can show up as swirls or waves in resin. Before using the kit again, gently warm it in a warm water bath. Moisture has contaminated the resin.

Q2: What is thermal paste?

A2: Thermal paste or thermal interface material (TIM) is an agent or material that transfers heat. It is used to fill gaps between two metals.

Q3: What is an RTV Silicone?

A3: An RTV (Room Temperature Vulcanization) silicone sealant is a sealant that begins to cure immediately upon being exposed to air (specifically the moisture present in the air), as opposed to water based sealants such latex.

Q4: Is silicone lubricant the same as silicone grease?

A4: Silicone grease Silicone grease and paste are frequently meant the same thing. They are used for lubrication and because they wrap the area of application they protect the parts from rust and elements.

Q5: Is silicone gel a polymer?

A5: "Silicone gels" are optimized polymeric resins used for such applications, especially for protecting surfaces of organic integrated circuit chips due to their ability to replace conventional ceramic hermetic packaging.

Hot Searches