- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v/220v or customized

-

Dimension(L*W*H):

-

depends on model

-

Weight:

-

5200 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Tin ore processing Plant

-

Usage:

-

Alluvial tin,rock tin ore separation

-

Feeding size:

-

depends on the ore size

-

Model Number:

-

as customized

-

Capacity:

-

1-500tph

-

Processed materials:

-

alluvial tin,rock tin ore

-

Test&Installation:

-

Senior Professional Engineers Assigned

-

Spare parts supply:

-

Lifelong Provide

-

Factory visit:

-

Welcomed Warmly

Quick Details

-

Production Capacity:

-

1-500tph

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC

-

Voltage:

-

380v/220v or customized

-

Dimension(L*W*H):

-

depends on model

-

Weight:

-

5200 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Tin ore processing Plant

-

Usage:

-

Alluvial tin,rock tin ore separation

-

Feeding size:

-

depends on the ore size

-

Model Number:

-

as customized

-

Capacity:

-

1-500tph

-

Processed materials:

-

alluvial tin,rock tin ore

-

Test&Installation:

-

Senior Professional Engineers Assigned

-

Spare parts supply:

-

Lifelong Provide

-

Factory visit:

-

Welcomed Warmly

Product Description

Overview

The beneficiation method of placer tin ore is similar to that of placer gold ore, which is generally treated by gravity separation method and equipment. For placer tin ore with high monomer dissociation, the beneficiation is basically the same as that of placer gold ore. better beneficiation indexes can be obtained through simple screening and washing. For placer tin ore with low monomer dissociation, rod grinding and other processes are often needed to break the continuous structure in order to improve the beneficiation recovery and concentrate grade.

The gravity separation of placer tin ore is also based on the principle of gravity beneficiation. It is sorted according to the

specific gravity difference between tin and waste rock. Due to the large specific gravity difference between tin and waste rock in placer tin ore, a good beneficiation effect can be obtained by using gravity separation methods and equipment. At the same time, it has the advantages of high efficiency, energy-saving and environmental protection, small equipment investment, and low operation cost. It is an ideal choice for placer tin ore beneficiation.

specific gravity difference between tin and waste rock. Due to the large specific gravity difference between tin and waste rock in placer tin ore, a good beneficiation effect can be obtained by using gravity separation methods and equipment. At the same time, it has the advantages of high efficiency, energy-saving and environmental protection, small equipment investment, and low operation cost. It is an ideal choice for placer tin ore beneficiation.

The equipment for gravity separation of placer tin ore is mainly jig. Sometimes, in order to improve the recovery rate of

fine-grained tin ore, a shaking table will also be used. The process flow of tin ore gravity separation is screening → jigging → dehydration. For placer tin ore with low monomer dissociation, it often needs to go through two gravity separation processes: screening → jig → rod mill → jig → dehydration. Gravity separation is the most ideal, economical, and effective tin ore dressing method. The sand tin ore gravity separation equipment has a small investment, low operation cost, and no pollution to the environment. The screening gravity separation method is used to treat the sand tin ore in major sand tin washing plants and tin mining ships. The beneficiation effect is good and the application is very common.

fine-grained tin ore, a shaking table will also be used. The process flow of tin ore gravity separation is screening → jigging → dehydration. For placer tin ore with low monomer dissociation, it often needs to go through two gravity separation processes: screening → jig → rod mill → jig → dehydration. Gravity separation is the most ideal, economical, and effective tin ore dressing method. The sand tin ore gravity separation equipment has a small investment, low operation cost, and no pollution to the environment. The screening gravity separation method is used to treat the sand tin ore in major sand tin washing plants and tin mining ships. The beneficiation effect is good and the application is very common.

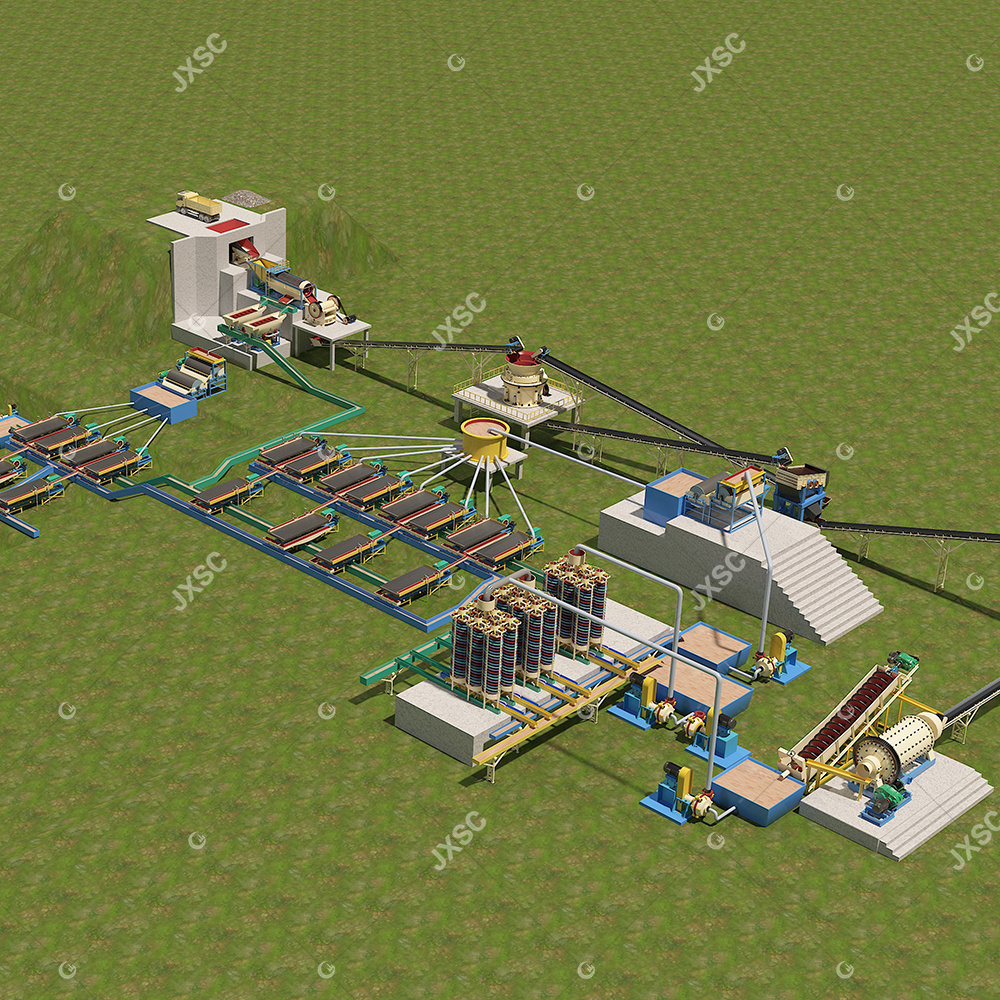

100 TPH Alluvial Tin and Rock Tin Process Flowchart Explanation ▼

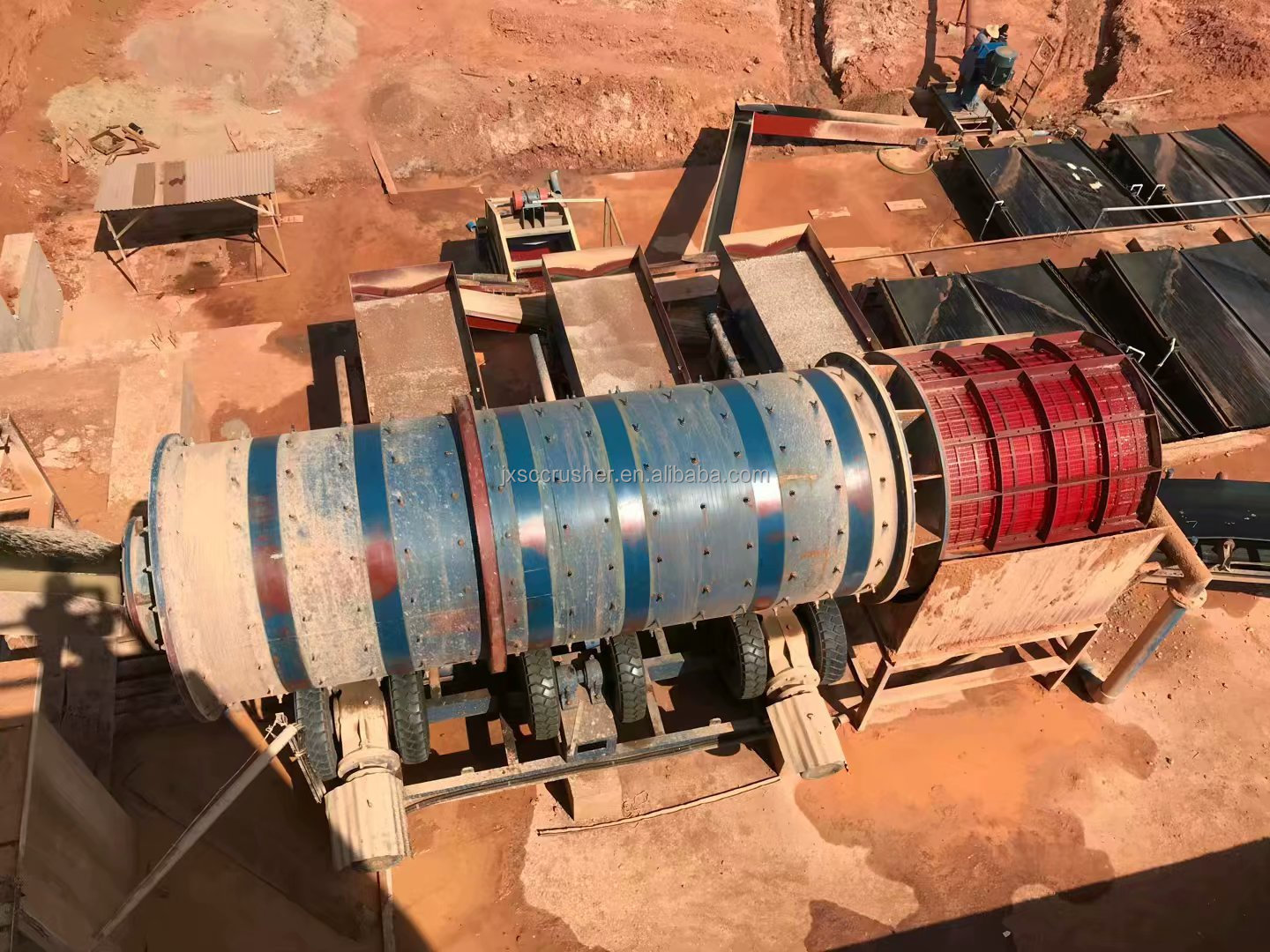

1. This setup is one 100tph alluvial tin and Rock tin processing plant, it is configured with a trommel screen, jaw crusher, cone crusher, vibrating screen, belt conveyor, ball mill, spiral classifier, spiral chute separator, magnetic separator, shaking table, jig machine, dewatering screen, and dryer machine.

2. The raw ore feed into the trommel screen for washing a few little clays, and can separate the gravel or stone which needs to crush&grind to get the inside tin, the separated gravel can transfer to the next jaw crusher by the belt conveyor. After the jaw crusher, goes to a cone crusher for second crushing. The output from the cone crusher goes to a vibrating screen for sieving. The overscreen size back to cone crusher for crushing again.

3. The under-screen particles will go to the ball mill for grinding. There is one hopper for transferring and buffering materials before being fed into the ball mill. Under the hopper, there is an Electromagnetic vibration feeder for feeding the material more evenly. Ball mill and spiral combination circulating closed-circuit system, which can make sure the final output meets less than 200mesh (0.074mm) The small fine particles from the spiral classifier will transport to first stage spiral chute separator by a slurry pump. The middlings from the first stage spirals separator will go to the second stage spirals separator. All the concentrates from the spiral separators will transport to two drums magnetic separators to separate the iron/Fe material( Like magnetite, hematite).

4.After separating the Iron first, the others mineral-like tin (which do not contain the magnetism) will go to a two-stage shaking table for Tin separation. The middlings from the first stage shaking table will go to the second stage shaking table for beneficiation again to improve the recovery rate. The shaking table quantities can adjust based on your mine situation and requirements.

5. The under-screen from the first trommel screen machine will go to the jig machine. The jig screen meshes with a

2mm aperture. The concentrates from the jig machine go to two drums magnetic separator separate the iron/Fe material first. After removing the iron, then goes to the shaking table for Tin separation. The middlings from the first stage shaking table will go to the second stage shaking table for beneficiation again to improve the recovery rate.

2mm aperture. The concentrates from the jig machine go to two drums magnetic separator separate the iron/Fe material first. After removing the iron, then goes to the shaking table for Tin separation. The middlings from the first stage shaking table will go to the second stage shaking table for beneficiation again to improve the recovery rate.

6. All the final tin concentrates from the second stage shaking table will go to the dryer machine for drying.

7. All the tailings from the jig machine, spiral chute separator, and shaking tables will go to a dewatering screen via a slurry pump for dewatering. After precipitation, the water can be recycled. The overscreen waste can transport away by belt conveyor.

4.The

three disc dry magnetic separator

is a Dry Intensified Magnetic Separator, applicable for separations of coltan, zircon, rutile etc

Successful Cases

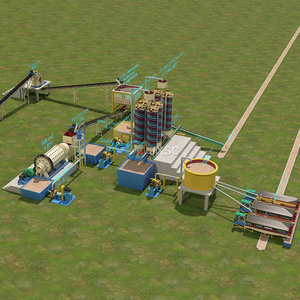

100T/H Tin /Ta & Nb ore processing plant in Uganda

JXSC company have built a 100T/H Ta & Nb ore processing plant in Uganda. We provided “turnkey solution” to our clients in this project. Details include below:

● Mining project processing consulting at beginning.

● Design and draw flowchart.

● Engineer go to mine site to check the mine and ore before starting.

● Providing complete set processing equipments.

● Dispatching engineer to customer’s mine site for guidance of equipments installation, commissioning and training worker.

Ta&Nb ore condition: most of ore is alluvial type, some are bigger size rock type, so firstly need to separate out big particles to crush to smaller size, the use the gravity processing machine to separate out Ta&Nb. Main machines include: vibrating feeder->vibration screen-> belt conveyor-> cone crusher-> belt conveyor->jig separator-> shaking table

100TPH Capacity Complete Set Tin/Coltan Processing Plant in Nigeria

Hopper->Vibrating Feeder->Trommel Scrubber->Jig Separator->(roll crushing mill->)Vibration Screen->Slurry Pump->Shaking Table->Air Dryer->three disc magnetic separator

1) We supplied the full plant for this tin& coltan project.

● Hopper was produced on customer's coltan site of rolled steel

● Vibration Feeder, capacity 100tph, sieve size 80mm, Model ZSW420X110, 1SET

● Trommel Scrubber washing machine, screen mesh 5mm, capacity 100tph, Model 1500, 1SET

● Jig Separator, capacity 25tph/set, Model JT6-3, total 4SETS

● Roll Crushing Mill, Model PC-800x600, 1SET

● Vibration Screen, capacity 30-90tph, JXSC-1536, total 2SETS

● Slurry Pump, flow 80-136m3/h, Model 4PNJ, 1SET

● Shaking Table, Model 6-s, total 7SETS

● Three Disc Magnetic Separator, Capacity 120-800kg/h, Model 3PC-600, 1SET

2) We dispatched our chief engineer Mr. Lee and engineer Mr. Wen service at mining site.

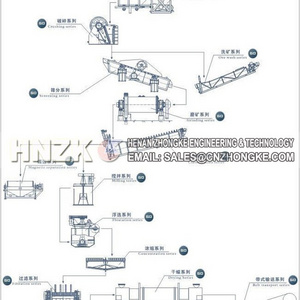

Other Flowchart

Not only tin ore, our factory also can make gold ore machine line, chrome ore machine line, tin ore machine line, iron ore machine line, diamond ores machine line and so on.

Packaging & Delivery

|

1.Small parts packed in the wooden cases.

|

|

2.Big parts packed by plastic membrane.

|

|

3.The whole big machine is loaded in the container.

|

Company Introduction

JXSC mine machinery factory located in Jiangxi province. we are a professional company providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore / Diamond/ Coltan ore / Silica sand / Zircon sand/ Black sand/Chrome ore, ect.

1.+30years history factory at mining machinery

2.Provide engineer team after sale service

3.Provide complete set mineral processing plant

4.Provide sample testing service in factory lab for free

5.Provide professional mining solution consulting

1. Inquiry and consulting support.

2. Ore sample testing support.

3. View our Factory.

4. Design Flowchart.

1. Training how to instal the machine, training how to use the machine.

2. 1 year warranty .

3. Engineers available to service machinery overseas.

FAQ

1.How is the quality of your products?(mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will do a test on every machine before delivery.

1. Which machine do you need? like gold washing machine, spiral chute, vibrating screen, Jig separator, Shaking table, etc.

2. What is your raw ore that you plan to process? like gold ore, diamond ore, tantalite or silica sand, etc.

3. What is the capacity you need? Like 10 tones per hour.

4. What is the feeding size to the machine? and what is the discharging-material size that you require?

Sincerely welcome to send your inquiry,you can get best quotation and professional service.

Answer: Our products are manufactured strictly according to national and international standard, and we will do a test on every machine before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description or promise we made before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.

If you are interested in our products, please don't hesitate to contact us. Could you tell me the following questions, so that I can give you a complete solution, including best Exw-works Price Quotation!

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description or promise we made before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.

If you are interested in our products, please don't hesitate to contact us. Could you tell me the following questions, so that I can give you a complete solution, including best Exw-works Price Quotation!

1. Which machine do you need? like gold washing machine, spiral chute, vibrating screen, Jig separator, Shaking table, etc.

2. What is your raw ore that you plan to process? like gold ore, diamond ore, tantalite or silica sand, etc.

3. What is the capacity you need? Like 10 tones per hour.

4. What is the feeding size to the machine? and what is the discharging-material size that you require?

Sincerely welcome to send your inquiry,you can get best quotation and professional service.

Hot Searches