- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

1500 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HY

-

Year:

-

2020/2021

-

Power (kW):

-

220KW

-

Weight (KG):

-

6000 KG

-

Product name:

-

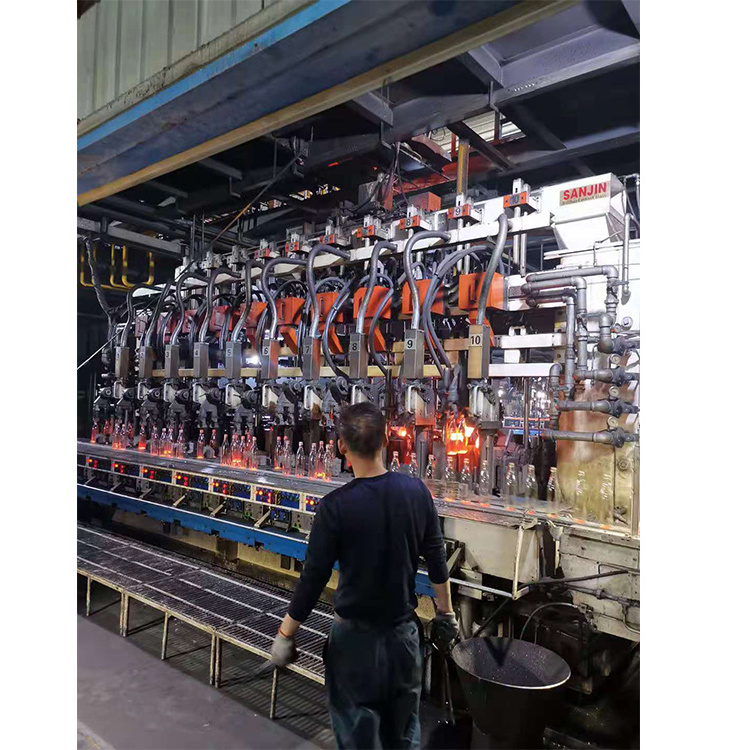

glass Blow Molding Machine

-

glass bottle making machine:

-

glass bottle

-

Blow Moulding Type:

-

Stretch Blow Moulding

-

Marketing Type:

-

New Product 2021

Quick Details

-

Neck Diameter(mm):

-

36 mm

-

Max.Bottle Diameter(mm):

-

320 mm

-

Max.Bottle Height(mm):

-

320 mm

-

Bottle Volume(ml):

-

1500 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HY

-

Year:

-

2020/2021

-

Power (kW):

-

220KW

-

Weight (KG):

-

6000 KG

-

Product name:

-

glass Blow Molding Machine

-

glass bottle making machine:

-

glass bottle

-

Blow Moulding Type:

-

Stretch Blow Moulding

-

Marketing Type:

-

New Product 2021

Products Description

|

Serial number

|

Model number

|

Equipment name

|

Selling price

|

Productivity

(500ml bottle) |

|

1

|

|

Bottle Preform dumper

|

14,000 USD

|

|

|

2

|

|

Bottle preform ion air deduster

|

28,000 USD

|

|

|

3

|

300ml-1250ml bottle

|

Blow mould

|

2300 USD/cavity

|

|

|

4

|

1500ml bottle

|

Blow mould

|

3500 USD/cavity

|

|

|

5

|

5000ml bottle

|

Blow mould

|

16,000 USD/cavity

|

|

|

6

|

ZYCP-4 (Big)

|

4-cavity bottle blowing machine

|

410000USD

|

Water bottle/4500 bottles/hour

(5L big bottle) |

|

7

|

ZYCP-6 (Big)

|

6-cavity bottle blowing machine

|

503000USD

|

Water bottle/6500 bottles/hour (5L big bottle)

|

|

8

|

ZYCP-6

|

6-cavity bottle blowing machine

|

310000USD

|

Water bottle/1200 bottles/hour; gas bottle/10000 bottles/hour; medium temperature bottle/10000 bottles/hour

|

|

9

|

ZYCP-8

|

8-cavity bottle blowing machine

|

350000USD

|

Water bottle/16000 bottles/hour; gas bottle/15200 bottles/hour; medium temperature bottle/12800 bottles/hour

|

|

10

|

ZYCP-10

|

10-cavity bottle blowing machine

|

380000USD

|

Water bottle/20,000 bottles/hour; with gas cylinder/19,000 bottles/hour, medium temperature bottle/16,000 bottles/hour

|

|

11

|

ZYCP-12

|

12-cavity bottle blowing machine

|

430000USD

|

Water bottle/24000 bottles/hour with gas cylinder/22800 bottles/hour, Medium temperature bottle/19200 bottles/hour

|

|

12

|

ZYCP-14

|

14-cavity bottle blowing machine

|

490000USD

|

Water bottle/28000 bottles/hour with gas cylinder/26600 bottles/hour

Medium temperature bottle/22400 bottles/hour |

|

13

|

ZYCP-16

|

16-cavity bottle blowing machine

|

552000USD

|

Water bottle/32000 bottles/hour, Gas cylinder/30400 bottles/hour, medium temperature bottle/25600 bottles/hour

|

|

14

|

ZYCP-18

|

18-cavity bottle blowing machine

|

610000USD

|

Water bottle/36000 bottles/hour with gas bottle/34200 bottles/hour, Medium temperature bottle/28800 bottles/hour

|

|

|

ZYCP-20

|

20-cavity bottle blowing machine

|

720000USD

|

Water bottle/36000 bottles/hour with gas bottle/34200 bottles/hour, Medium temperature bottle/28800 bottles/hour

|

|

15

|

ZYCP-20

|

20-cavity bottle blowing machine

|

800000USD

|

Water bottle/40000 bottles/hour

Gas cylinder/38000 bottles/hour, medium temperature bottle/32000 bottles/hour |

|

16

|

ZYCP-24

|

24-cavity bottle blowing machine

|

1050000USD

|

Water bottle/48000 bottles/hour, gas cylinder/43000 bottles/hour, Medium temperature bottle/43000

|

Filling line:

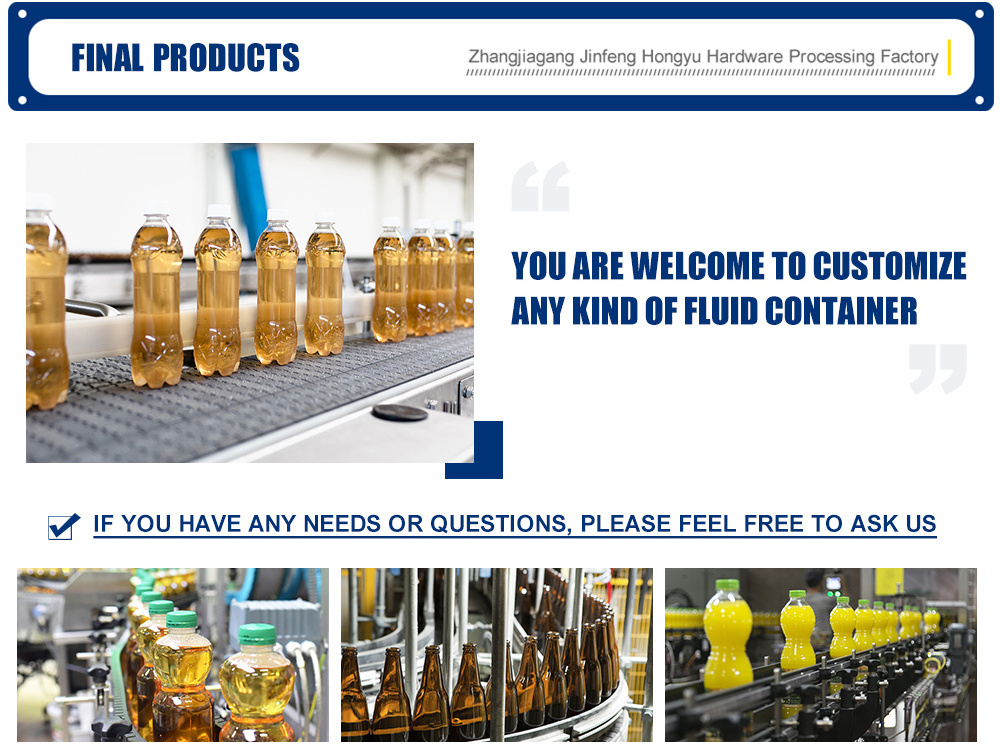

This machine is a filling machine, mineral water filling machine, pure water filling machine, this XGF washing and filling top

cover three-in-one unit: the beverage machine is used to produce polyester bottled mineral water, pure water, alcoholic beverage machinery and other non-gas Beverage machinery. CGF washing-filling-capping three-in-one equipment: the beverage machine can complete all the processes of bottle pressing, filling and sealing, which can reduce the contact time of materials and the outside world, improve sanitary conditions, production capacity and economic benefits.

Features:

1. Adopt the technology of air supply and transfer wheel to directly connect the bottle mouth; the screw and conveyor chain are eliminated, which makes it easier to change the bottle shape.

2. The bottle transmission adopts clip bottleneck technology, the bottle shape transformation does not need to adjust the

equipment level, just change the relevant bending plate, wheel and nylon parts.

3. The specially designed stainless steel bottle washing machine clip is sturdy and durable, and has no contact with the screw position of the bottle mouth, which can avoid secondary pollution.

4. Filling valve with high speed and large gravity flow valve, fast filling speed, accurate filling and no liquid loss.

5. The screw descends when the bottle is discharged, and the height of the conveyor chain is not required to adjust the bottle shape.

This machine is a filling machine, mineral water filling machine, pure water filling machine, this XGF washing and filling top

cover three-in-one unit: the beverage machine is used to produce polyester bottled mineral water, pure water, alcoholic beverage machinery and other non-gas Beverage machinery. CGF washing-filling-capping three-in-one equipment: the beverage machine can complete all the processes of bottle pressing, filling and sealing, which can reduce the contact time of materials and the outside world, improve sanitary conditions, production capacity and economic benefits.

Features:

1. Adopt the technology of air supply and transfer wheel to directly connect the bottle mouth; the screw and conveyor chain are eliminated, which makes it easier to change the bottle shape.

2. The bottle transmission adopts clip bottleneck technology, the bottle shape transformation does not need to adjust the

equipment level, just change the relevant bending plate, wheel and nylon parts.

3. The specially designed stainless steel bottle washing machine clip is sturdy and durable, and has no contact with the screw position of the bottle mouth, which can avoid secondary pollution.

4. Filling valve with high speed and large gravity flow valve, fast filling speed, accurate filling and no liquid loss.

5. The screw descends when the bottle is discharged, and the height of the conveyor chain is not required to adjust the bottle shape.

More Products

Hot Searches