- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

83kg

-

Product:

-

18 kw electric steam generator

-

Rated power:

-

18 kw

-

Rated steam capacity:

-

25 Kg/h

-

Rated working pressure:

-

0.7Mpa

-

OEM/ODM service:

-

Acceptable

-

Combustion method:

-

Electric heating

-

Color:

-

Blue

-

Custom processing:

-

Yes

-

Voltage:

-

380V

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Jiangxin

-

Dimension(L*W*H):

-

70cm*45cm*113cm

-

Weight:

-

83kg

-

Product:

-

18 kw electric steam generator

-

Rated power:

-

18 kw

-

Rated steam capacity:

-

25 Kg/h

-

Rated working pressure:

-

0.7Mpa

-

OEM/ODM service:

-

Acceptable

-

Combustion method:

-

Electric heating

-

Color:

-

Blue

-

Custom processing:

-

Yes

-

Voltage:

-

380V

The 18 kw electric steam boiler is mainly composed of a water supply system, an automatic control system, a furnace and a heating system, and a safety protection system. The working principle is: through an automatic control device to ensure that the liquid controller or high, medium and low electrode probes feedback control the opening and closing of the water pump during operation, the length of water supply, and the heating time of the furnace.

The maximum steam pressure is set, and the water level of the furnace is continuously decreased with the continuous output of steam. When it is in the low water level (mechanical type) and the middle water level (electronic type), the water pump automatically replenishes the water.

When the water level of the 18 kw electric steam boiler is high, the water pump stops the water supply; At the same time, the electric heating tube in the furnace continues to heat, and the source continuously generates steam. The pointer pressure gauge on the upper part of the panel or the top part immediately displays the steam pressure value, and the whole process can be automatically displayed by the indicator light.

The 18 kw electric heating boiler parameters are as follows:

Features of 18 kw electric steam boiler

1. Heat pipe: multiple heat pipes can improve efficiency and extend life

2. Liquid level control system: reliable liquid level control system, safer

3. Pressure control system: high precision pressure control system control is more precise

4. Electrical components: well-known brand custom components

5. Circuit board: The control system independently developed and produced is safer and more reliable.

6. Liner: professional boiler steel plate professional anti-corrosion treatment

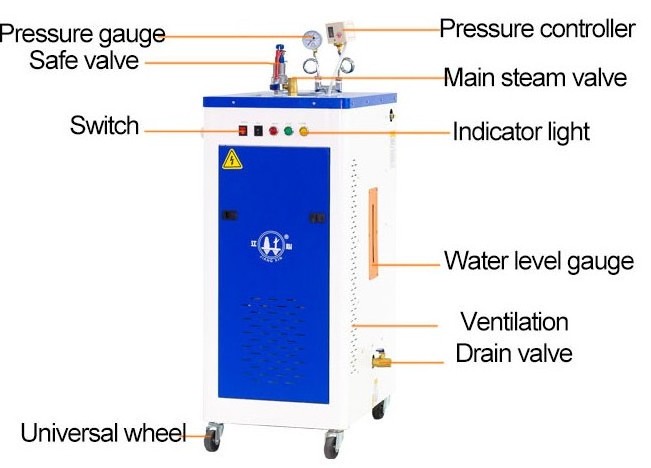

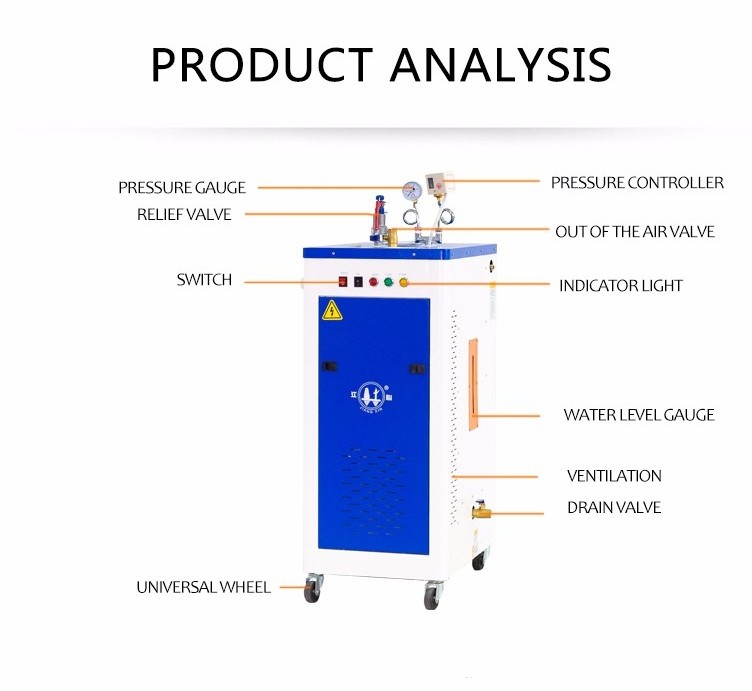

Original equipment manufacturer used 18 kw electric heating steam generator accessories including safe valve, switch, universal wheel, pressure controller, out of the air valve, pressure gauge, indicator light, water level gauge, ventilation and drain valve.

This type of product has the advantages of intelligent one machine, labor saving, provincial installation fee, economical and energy saving, stable gas supply, lifetime maintenance, environmental protection and energy saving

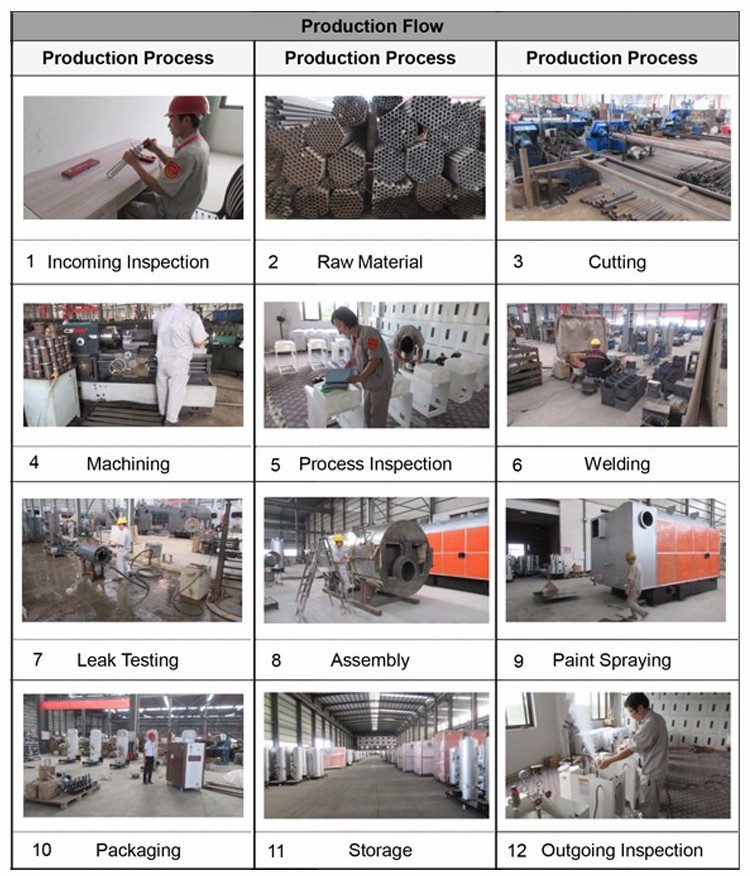

Jiangxin is mainly produce all kinds of boilers for customers. The entire production process includes the use of raw materials - processing - product storage.

In the current production process of Jiangxin, six processing workshops are involved with twelve processes. Each process is completed in a specific workshop. The correspondence is as follows:

In the process of production and processing, each workshop team member completes the process content of the workshop. At the beginning of each process, it is necessary to use raw materials and semi-finished products in a specific warehouse. At the completion of each process, semi-finished products and finished products need to be sent to a specific warehouse. Processing of different products will have different processing steps, but the processing workshop and the warehouse for storing items are fixed.