- Product Details

- {{item.text}}

Quick Details

-

Raw materials:

-

Cement

-

Product name:

-

lightweight wall panel machine

-

Color:

-

Demand

-

Main process:

-

Forming Demoulding

-

Advantage:

-

Longer Working Time

-

Name:

-

Lightweight Wall Panel Molding Machine

-

Quality:

-

Good

-

Keywords:

-

prefabricated concrete wall brick making machine

-

Certification:

-

ISO CE

Quick Details

-

Place of Origin:

-

Henan, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

Type:

-

concrete wall panel making machine/concrete prefabricated houses

-

Raw materials:

-

Cement

-

Product name:

-

lightweight wall panel machine

-

Color:

-

Demand

-

Main process:

-

Forming Demoulding

-

Advantage:

-

Longer Working Time

-

Name:

-

Lightweight Wall Panel Molding Machine

-

Quality:

-

Good

-

Keywords:

-

prefabricated concrete wall brick making machine

-

Certification:

-

ISO CE

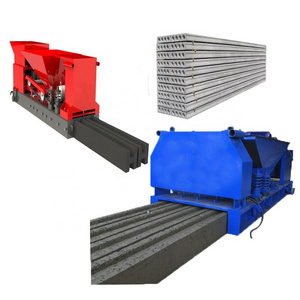

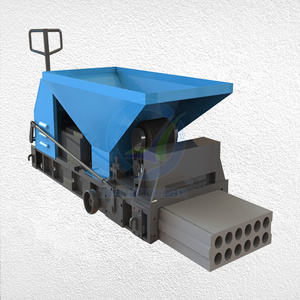

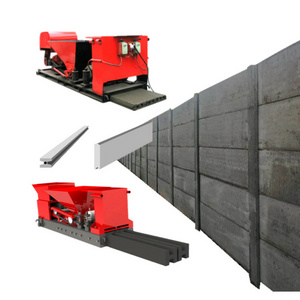

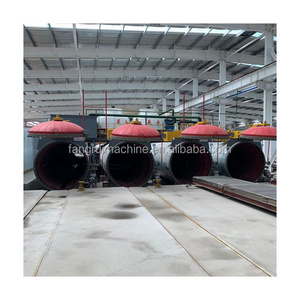

Lightweight wall panel making machine price precast concrete fence mold gypsum panel production line

Lightweight wall panel making machine price precast concrete fence mold gypsum panel production line

Introduction of concrete prefabricated houses wall panel making machine:

1. Extensive use of hard wear-resistant alloy of the precast concrete buildings concrete

fence post mould/concrete pole mould

2. To use the best Vibrator and Reducer of the precast concrete buildings concrete fence

post mould/concrete pole mould

3. Precast concrete pole column extruder machine works on long-line table; use the flat pushing work method to form the concrete purlin/column, 60% steel material will be saved which compared with traditional revolving die method.

4. Efficiency can be improved 3 to 5 times compared with conical die method, the machine is easy for operation and convenient for maintenance, the products made by the machine are in good quality, smooth surface and accurate size.

Feature of concrete prefabricated houses wall panel making machine:

1. The machine is used for making the prestressed concrete post and beam.

2. The machine is used for slipformer and extruder technology.

3. The raw materials are cement, sand and Aggregate.

4. The machine can make 1.2-1.4m concrete lintel and beam.

5. The prestressed system can prestress the steel wire.

6. The machine can make different sizes of concrete lintel.

Advantages of concrete prefabricated houses wall panel making machine:

Excellent profitability

Low production cost

Minimum energy requirement

Minimum labor

Little production area requirement

Environment-friendly production: no pollution, noiseless and no vibrations are produced

Easy handling and maintenance

Factory automation according to customer's requirements

Application of concrete prefabricated houses wall panel making machine:

The Finished product is a high quality and economic construction component for partition wall board purpose , The walls highly are suited for areas with high degree of moisture e.g.bathrooms ,kitchens and shower room as well as areas where good sound insulation is needed,such as apartments ,hotels and schools . Besides, the walls can bu installation in workshop,structure buildings.

Technical parameters of concrete prefabricated houses wall panel making machine:

|

Type |

Thickness(mm) |

Width(mm) |

Molding speed(m/min) |

Hole number |

hole diameter(mm) |

|

MN60*600 |

60 |

600 |

1.3---1.5 |

12 |

32 |

|

MN80*600 |

80 |

600 |

1.3---1.5 |

8 |

48 |

|

MN90*600 |

90 |

600 |

1.3---1.5 |

7 |

58 |

|

MN100*600 |

100 |

600 |

1.3---1.5 |

6 |

68 |

|

MN110*600 |

11 |

600 |

1.3---1.5 |

6 |

68 |

|

MN120*600 |

120 |

600 |

1.3---1.5 |

5 |

88 |

|

MN130*600 |

130 |

600 |

1.3---1.5 |

5 |

88 |

|

MN140*600 |

140 |

600 |

1.3---1.5 |

5 |

88 |

|

MN150*600 |

150 |

600 |

1.3---1.5 |

5 |

100 |

|

MN160*600 |

160 |

600 |

1.3---1.5 |

5 |

100 |