- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Alloy Steel

-

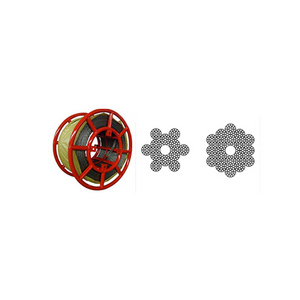

Product name:

-

Steel Hoisting Rope Guider Fairlead

-

Process:

-

sand casting

-

Dimensions:

-

Customized Dimension

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

no

-

Model Number:

-

no

-

Material:

-

Alloy Steel

-

Product name:

-

Steel Hoisting Rope Guider Fairlead

-

Process:

-

sand casting

-

Dimensions:

-

Customized Dimension

| Accurate in reading drawings & Fast in delivery & Exact dimension control & 100% quality control & OEM Service & Strict material inspection & Prompt quote & lead time guarantee | |

| 1.Product Name: | Steel Hoisting Rope Guider Fairlead |

| 2. Material: | Alloy steel |

| 3.Material Standard: | ASTM,AISI,ASME,SAE,NF EN,DIN EN,ISO,,BS EN,SS,etc. |

| 4. Items: | FOB Ningbo or Shanghai,China |

| 5. Lead time: | 30~40 days |

| 6. Place of origin | Ningbo, China |

| 7. Software for specification drawings: | PDF, Auto CAD, Solidworks, JPG, ProE,etc. |

| 8. Main production equipments: | CNC-machine-center, Lathe, Milling machine,Drilling machine,Boring Lathe,Grinding Machine, Heat treatment Furnace. |

| 9.Heat Treatment Machine: | Mesh-Belt-Furnace,Carburizing Quench Furnace,Chamer Furnace,etc. |

| 10.Surface Treatment: | Cold/Hot Zn Plating,Blackening Treatment(Salt Spray Test 48-96 hours),Ni Plating,Cr Plating,Spraying Undercoat,Anti-Rust Paint,Surface Paint,Plastic Paint,Coated Anti-Rust Water,Anti-oil,etc. |

| 11.Surface Heat Treatment: | Medium Frequence Quenching,High Frequence Quenching and Carburizing and Quenching,Oil Quenching,Water quenching,Normalizing,Temper,Annealing,etc. |

| 12.Dimension Inspection: | Calipers,Height Laugue,Micrometer Calipers,Inside Caliper Gauge,Angle and R Gauge,Three coordinates measuring instrument. |

| 13. Productivity: | 50000 pcs / year |

| 14. Packaging: | Wooden package after mandatory treatment or other |

| 15. They are using for mining equipment,Construction equipment,Agricultural equipment and others. | |

| 16. We make Steel Hoisting Rope Guider Fairlead in Ningbo, China,process include sand casting,gravity casting and die casting. | |

| 17. Export Markets: Australia Steel Hoisting Rope Guider Fairlead parts; America Steel Hoisting Rope Guider Fairlead casting, U.S.A. United States Steel Hoisting Rope Guider Fairlead casting; Canada Steel Hoisting Rope Guider Fairlead casting parts; U.K. England, Britain Steel Hoisting Rope Guider Fairlead casting parts; Germany Steel Hoisting Rope Guider Fairlead casting parts; France Steel Hoisting Rope Guider Fairlead casting parts; Italy Steel Hoisting Rope Guider Fairlead casting parts; Spain Espana Steel Hoisting Rope Guider Fairlead casting parts; Holand Steel Hoisting Rope Guider Fairlead casting parts; South Africa Steel Hoisting Rope Guider Fairlead casting parts; Danmark Steel Hoisting Rope Guider Fairlead casting parts; Sweden Steel Hoisting Rope Guider Fairlead casting parts; Finland Steel Hoisting Rope Guider Fairlead casting parts; Austria Steel Hoisting Rope Guider Fairlead casting parts; Russia Steel Hoisting Rope Guider Fairlead casting parts; Lithuania Steel Hoisting Rope Guider Fairlead casting parts; Serbia Steel Hoisting Rope Guider Fairlead casting parts,etc. | |

| 18.Supplier:China Steel Hoisting Rope Guider Fairlead factory;China Precision company;China Co.,Ltd;China Steel Hoisting Rope Guider Fairlead INC;China Steel Hoisting Rope Guider Fairlead corporation;China Steel Hoisting Rope Guider Fairlead Manufacturer;China Steel Hoisting Rope Guider Fairlead supplier; China Steel Hoisting Rope Guider Fairlead, China Steel Hoisting Rope Guider Fairlead. | |

| 19.Relationship Information:Ningbo Steel Hoisting Rope Guider Fairlead factory;Ningbo Precision company;Ningbo Steel Hoisting Rope Guider Fairlead Co.,Ltd;Hangzhou Steel Hoisting Rope Guider Fairlead factory;Hangzhou Steel Hoisting Rope Guider Fairlead company;Hangzhou Steel Hoisting Rope Guider Fairlead Co.,Ltd;Zhejiang Steel Hoisting Rope Guider Fairlead company;Zhejiang Steel Hoisting Rope Guider Fairlead Co.,Ltd. | |

| If you have any other question, please feel free to contact us. | |

Sand casting process

|

|

|

1. Mould D esigning Strictly making 3D model based on customer's drawing dimensions, and mastered the contractibility rate for all types of material. |

2.Mold shaping sand mold is formed by packing sand into each half of the mold. The sand is packed around the pattern, which is a replica of the external shape of the casting. |

|

|

| 3.Sand Core Making The cores are positioned and the mold halves are closed and securely clamped together |

|

| 5. Smelting the Liquid Steel: Allocate the chemical composition and sampling before steel casting. |

6.

Spectrochemistry Analysis Inspection on materials by spectrometer testing.

|

|

7. Smelting the Liquid Steel:

Allocate the chemical composition and sampling before steel casting.

|

8.Spectrochemistry Analysis Inspection on materials by spectrometer testing. |

|

9. Pouring

In the conventional process, the shell is filled with molten metal by gravity pouring. |

10.Sand Cleaning Removing sand from castings when the surfaces are not going to red anymore. |

|

11.

Heat Treating

Carbon steel and low-alloy steel need normalizing and temper, oil-quenching, water-quenching and so on. We can set out different heat treatment method as per different requirement from customers.

|

12.Shot blasting treatment This process can make the products surface color to be the same and remove the polishing trace. In use of different dimensional steel ball could have different vision on the product surface.

|

|

13. Polishing Polishing is to modify the out of flatness on casting head after casting cuttig and to modify the burring and splashing in the process of casting cycle. |

14. Machining Cut the piece of raw material into a desired final shape and size. Now we have CNC, Lathe, milling machine, drilling machine, boring lathe and grinding machine. |

| 15.Quality Inspection Quality inspection on the machining dimension. Mainly tools we use is like specialized gauge and callipers, mircocalliper,three-dimensional and so on. | 16. Storage and Delivery Efficiency of package goods delivery on time per your shipping requests. |