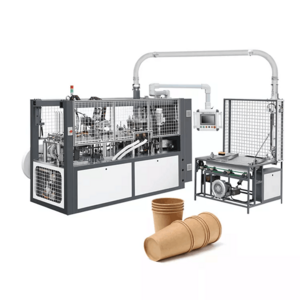

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

11KW

-

Dimension(L*W*H):

-

2800*1500*1800mm

-

Weight:

-

3000 kg

-

Product name:

-

PAPER BOWL MACHINE

-

Finished Products:

-

PAPER BOWL

-

Speed:

-

60-70PCS/MIN

-

Paper Cup Size:

-

MAX 1000ML

-

Certification:

-

CE

-

color:

-

customize

-

Function:

-

AUTOMATIC FORMING

-

After-sales Service:

-

ONLINE TEACHING

-

Material:

-

PE COATED PAPER

-

Total Power:

-

11KW

Quick Details

-

Production Capacity:

-

65pcs/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

GOOD

-

Voltage:

-

380V

-

Power:

-

11KW

-

Dimension(L*W*H):

-

2800*1500*1800mm

-

Weight:

-

3000 kg

-

Product name:

-

PAPER BOWL MACHINE

-

Finished Products:

-

PAPER BOWL

-

Speed:

-

60-70PCS/MIN

-

Paper Cup Size:

-

MAX 1000ML

-

Certification:

-

CE

-

color:

-

customize

-

Function:

-

AUTOMATIC FORMING

-

After-sales Service:

-

ONLINE TEACHING

-

Material:

-

PE COATED PAPER

-

Total Power:

-

11KW

Products Description

Machine details:

1. Paper cup bottom sealing by Leister CERAMIC hot air system, BRAND BANKO.

2. It is easy to make cups of different size by changing moulds.

3. Cup side sealing by ultrasonic.

4. Double PE coating paper cups for cold drink as well as hot drink.

5. Withour unique original designed bottom knurling system, single shaft, korea type, this ensures the low leaking ratio and

high quality of paper cups.

6. Paper sucking system adopt the vacuum pump, big power and stable running.

7. With unique single shaft design, the drive system is conducted by the stable gear system,it would be more stable when machine

running at a high speed.

8. With automatic lubricating system, it will automatic lubricating to every moving parts when machine runs.

9. Every cam will be harden to ensure it can run for a long long time.

10. Machine is designed with double turning plate

11. Equipped with automatic cup collecting stacking and counting system.

12. Bottom paper we have a special pre-feeding system, so the bottom paper feeding is “0”

Video link:https://youtu.be/xuUREfqEdFQ

2. It is easy to make cups of different size by changing moulds.

3. Cup side sealing by ultrasonic.

4. Double PE coating paper cups for cold drink as well as hot drink.

5. Withour unique original designed bottom knurling system, single shaft, korea type, this ensures the low leaking ratio and

high quality of paper cups.

6. Paper sucking system adopt the vacuum pump, big power and stable running.

7. With unique single shaft design, the drive system is conducted by the stable gear system,it would be more stable when machine

running at a high speed.

8. With automatic lubricating system, it will automatic lubricating to every moving parts when machine runs.

9. Every cam will be harden to ensure it can run for a long long time.

10. Machine is designed with double turning plate

11. Equipped with automatic cup collecting stacking and counting system.

12. Bottom paper we have a special pre-feeding system, so the bottom paper feeding is “0”

Video link:https://youtu.be/xuUREfqEdFQ

Recommend Products

Certifications

Exhibition

Hot Searches